Control method for ammonia spraying amount of denitration device and control device thereof

A control method and the technology of ammonia injection amount, applied in various fluid ratio control, injection devices, separation methods, etc., can solve the problems that the denitrification efficiency cannot guarantee the amount of ammonia escape, and the denitrification efficiency cannot meet expectations, so as to achieve accurate adjustment process And stable, eliminate residual error, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

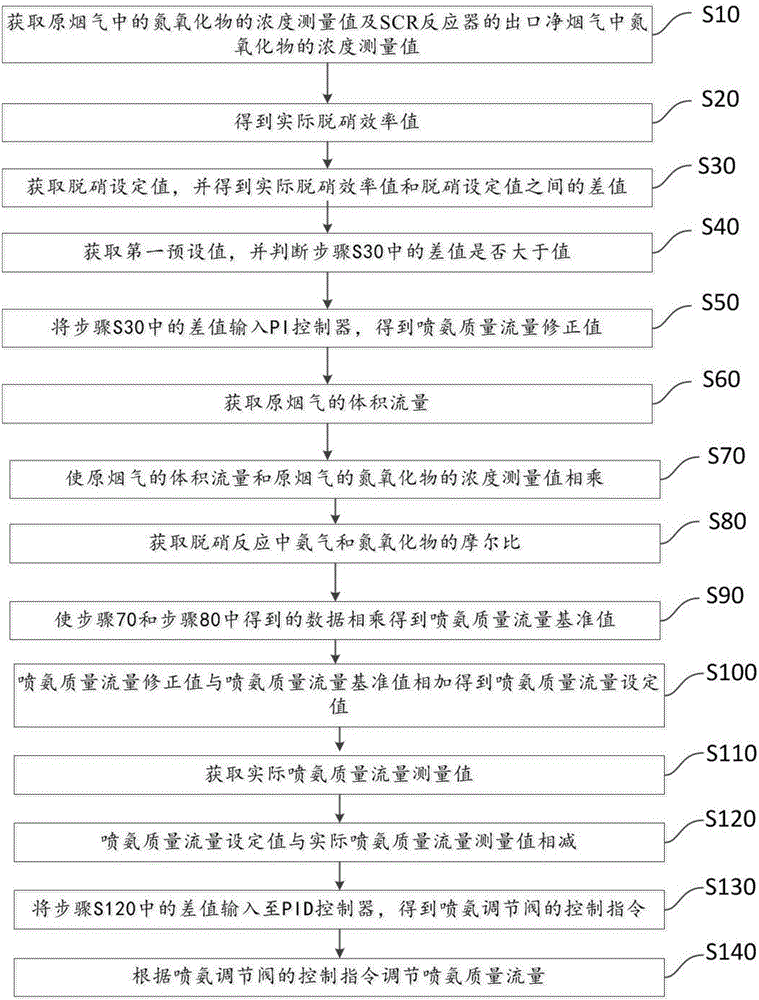

[0040] to combine figure 1 and figure 2 As shown, this embodiment 1 discloses a method for controlling the amount of ammonia sprayed by a denitrification device. The plate catalyst used in this embodiment is a vanadium-titanium-tungsten catalyst, and its main components include titanium dioxide, vanadium pentoxide, and tungsten trioxide. In the present invention, two layers of the catalyst are provided.

[0041] S10: Obtain the NO in the raw flue gas before entering the SCR reactor through the measurement of the first acquisition module 1 x The measured concentration is 355.1mg / Nm 3 NO in the net flue gas at the outlet of the SCR reactor x The measured concentration is 79.05mg / Nm 3 ;

[0042] S20: The NO in the raw flue gas obtained in the first acquisition module 1 x Concentration measurement value and NO in net flue gas x The actual denitrification efficiency value calculated from the concentration measurement value is 77.74%;

[0043] S30: Obtain the set value of t...

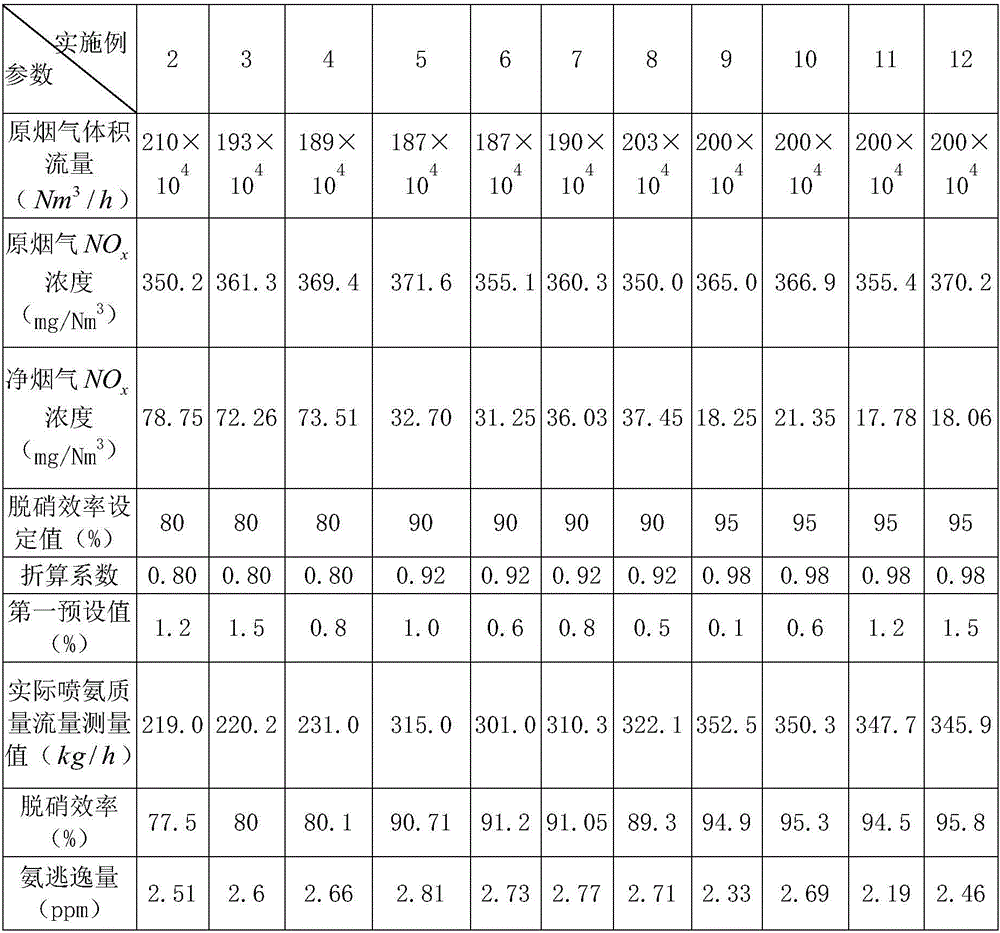

Embodiment 2 12

[0057] Table 1 shows eleven specific examples obtained according to the method in Example 1. Please refer to Table 1 for specific test parameters and results.

[0058] Table 1

[0059]

[0060] It can be seen from Table 1 that after adjusting the amount of ammonia injection by the method in the first embodiment, the denitrification efficiency is effectively guaranteed, and the amount of ammonia escape is controlled below 3ppm.

Embodiment 13

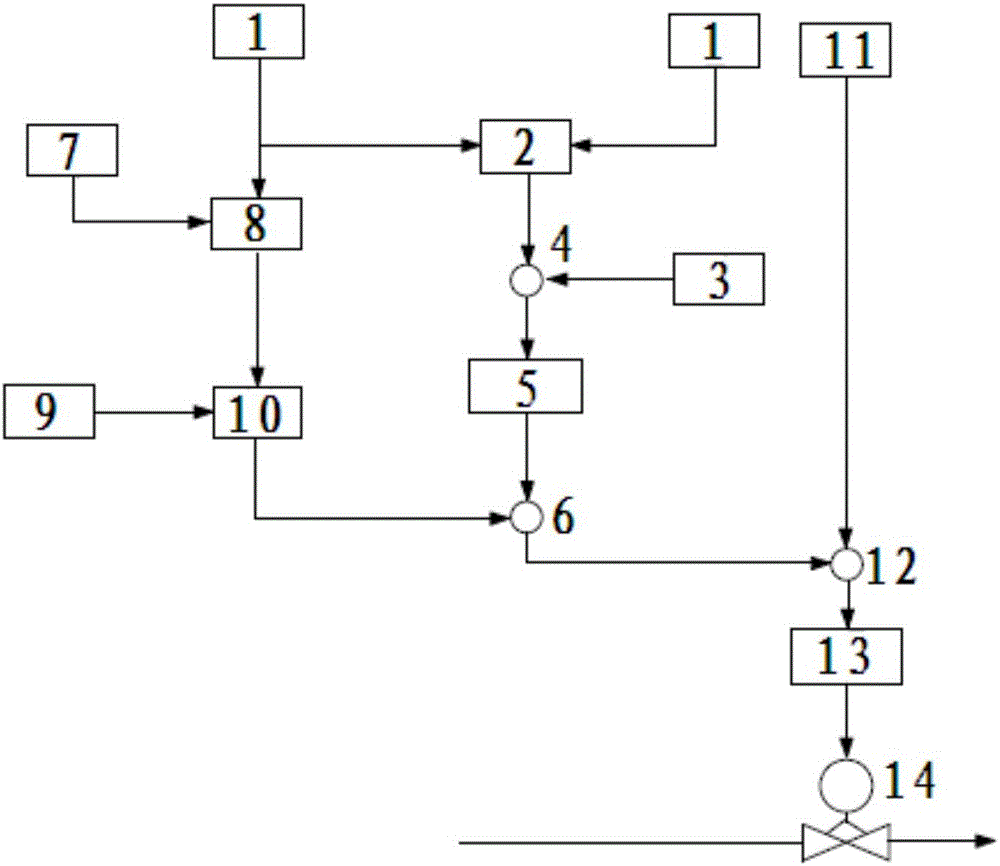

[0062] Such as figure 2 As shown, this embodiment discloses a control device for the amount of ammonia sprayed by a denitrification device. The control device includes: a first acquisition module 1 for obtaining NO in the raw flue gas at the entrance of the SCR reactor x The concentration measured value and the NO in the net flue gas at the outlet of the SCR reactor x Concentration measurement value; the first calculation module 2, connected with the first acquisition module 1, through the NO in the original flue gas x Concentration measurement value and NO in net flue gas x The concentration measurement value is calculated to obtain the actual denitration efficiency value; the second acquisition module 3 is used to obtain the denitration efficiency set value; the second calculation module 4 is connected to the first calculation module 2 and the second acquisition module 3 respectively, and is used for calculation to obtain The difference between the denitrification efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com