Integral pillow foaming production process and production device thereof

A production process and production device technology, which are applied in the field of an integrated pillow foam production process and production devices, can solve the problems of large space occupied by semi-finished products, great pressure on market price reduction, and increased production costs, thereby saving trimming time, The effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The integrated pillow foaming production process of the present invention, concrete process is as follows:

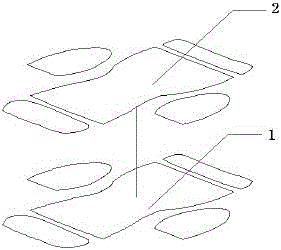

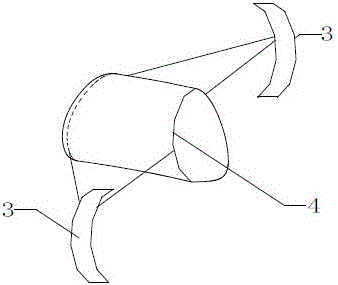

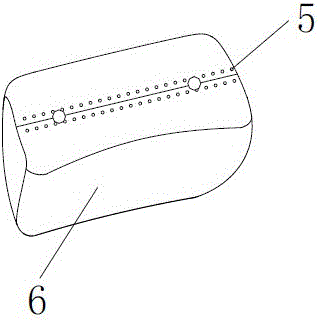

[0035] a. Pillow material epidermis is usually made of PVC / PU / velvet. Burn and paste PU film 2 on the back of the cut PVC / PU / velvet piece 1. Put the cut piece 1 together and press a single needle. The woven tape 3 is pasted to the 4 sewing lines of the cutting piece 1 to prevent material leakage. The non-woven tape 3 is hydrophobic, breathable, and impermeable to the material. It is used for foaming and degassing of the cotton, and the finished product 6 of the pillow skin assembly is turned over and sent to the next project;

[0036] b. The raw materials polyether polyol 7 and isocyanate 8 are sent to the material tank in the pumping room respectively, wherein the raw material polyether polyol-A material and isocyanate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com