Antibacterial and anti-mite laundry sheet and preparation method thereof

A laundry sheet and anti-mite technology, applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent powder/flake/sheet, etc., can solve the problem that the effect of machine washing is difficult to reach the level of laundry detergent and cannot meet the needs of consumption Consumers' consumption concepts, environmental consumers' adverse effects and other issues, to achieve the effect of raw material technology green environmental protection, good adsorption, and prevent hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

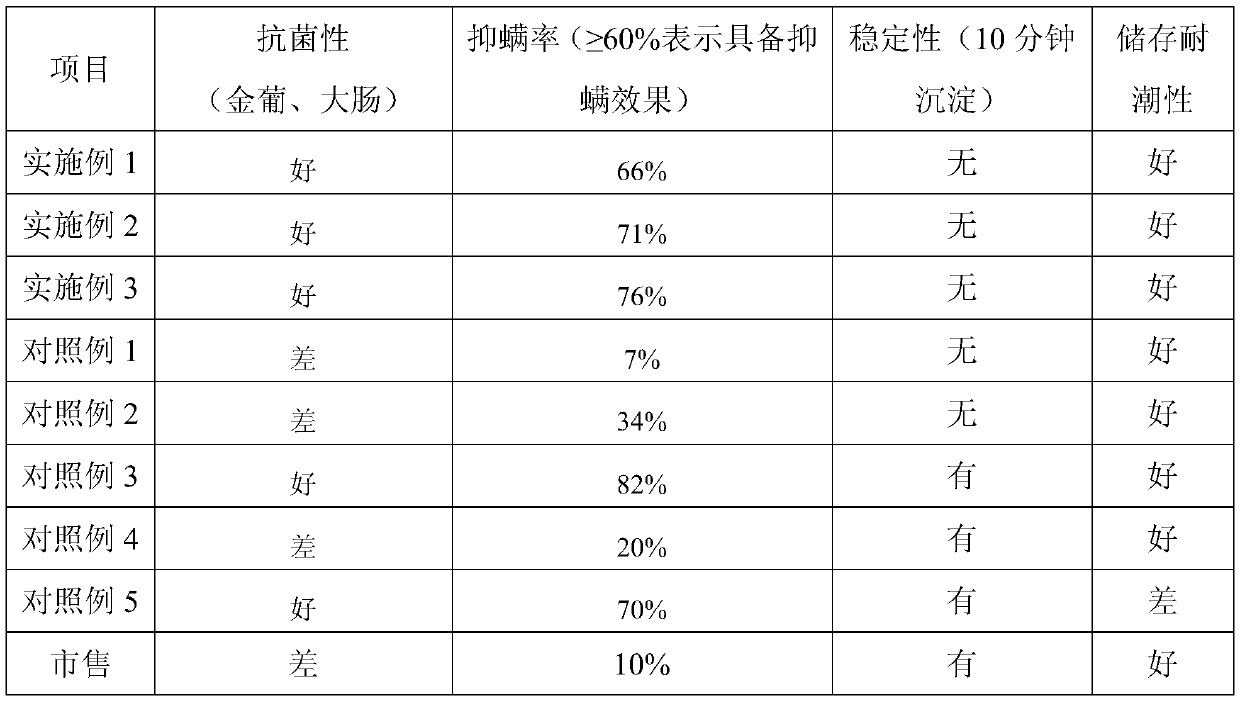

Examples

Embodiment 1

[0027] (1) Raw material components of antibacterial and anti-mite laundry tablets

[0028] 20 parts of alcohol ether glycoside, 10 parts of sodium fatty acid methyl ester sulfonate, 5 parts of sodium α-alkenyl sulfonate, 10 parts of fatty alcohol ether sodium sulfate, 30.0 parts of deionized water, 0.5 parts of crosslinking agent, microcapsules of wormwood essential oil 1.0 parts, absolute ethanol 2.0 parts, glutinous rice milk 1.0 parts, carboxymethyl starch sodium 6.0 parts, protease 0.2 parts, citric acid 0.1 parts, essence 0.01 parts, coloring agent 0.02 parts, preservative 0.01 parts.

[0029] (2) Preparation steps

[0030] Step 1: Add deionized water into the emulsifier and turn on the stirring device. Add the weighed cross-linking agent, colorant, citric acid, essence, and preservative in sequence, and stir for 10 minutes.

[0031] Step 2: Add the weighed alcohol ether glycoside, sodium fatty acid methyl ester sulfonate, sodium α-alkenyl sulfonate, sodium fatty alcoho...

Embodiment 2

[0039] (1) Raw material components of antibacterial and anti-mite laundry tablets

[0040] 25 parts of alcohol ether glycoside, 15 parts of sodium fatty acid methyl ester sulfonate, 5 parts of sodium α-alkenyl sulfonate, 10 parts of fatty alcohol ether sodium sulfate, 50.0 parts of deionized water, 1.0 part of crosslinking agent, 2.0 parts of cinnamon essential oil microcapsules 4.0 parts of absolute ethanol, 2.0 parts of glutinous rice milk, 8.0 parts of sodium carboxymethyl starch, 0.4 parts of protease, 0.5 parts of citric acid, 0.5 parts of essence, 0.03 parts of coloring agent, and 0.02 parts of preservative.

[0041] (2) Preparation steps

[0042] Step 1: Add deionized water into the emulsifier and turn on the stirring device. Add the weighed cross-linking agent, colorant, citric acid, essence, and preservative in sequence, and stir for 10 minutes.

[0043] Step 2: Add the weighed alcohol ether glycoside, sodium fatty acid methyl ester sulfonate, sodium α-alkenyl sulfo...

Embodiment 3

[0051] (1) Raw material components of antibacterial and anti-mite laundry tablets

[0052] 30 parts of alcohol ether glycoside, 12 parts of sodium fatty acid methyl ester sulfonate, 3 parts of sodium α-alkenyl sulfonate, 15 parts of fatty alcohol ether sodium sulfate, 60.0 parts of deionized water, 1.0 part of crosslinking agent, microcapsules of eucalyptus essential oil 2.0 parts, 1.0 parts of cinnamon essential oil microcapsules, 6.0 parts of absolute ethanol, 3.0 parts of glutinous rice milk, 12.0 parts of sodium carboxymethyl starch, 0.8 parts of protease, 1.0 parts of citric acid, 0.8 parts of essence, 0.04 parts of coloring agent, preservatives 0.03 parts.

[0053] (2) Preparation steps

[0054] Step 1: Add deionized water into the emulsifier and turn on the stirring device. Add the weighed colorant, citric acid, essence and preservative in turn, and stir for 10 minutes.

[0055] Step 2: Add the weighed alcohol ether glycoside, sodium fatty acid methyl ester sulfonate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com