Focal plane detection apparatus, focal plane calibration method and silicon chip aeration method

A technology of detection device and calibration method, which is used in testing optical performance, microlithography exposure equipment, photolithography process exposure device, etc., can solve actual focal plane drift, calibration and compensation of optimal focal plane offset, height and problems such as tilt deviation, to achieve the effect of good measurement accuracy and measurement repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

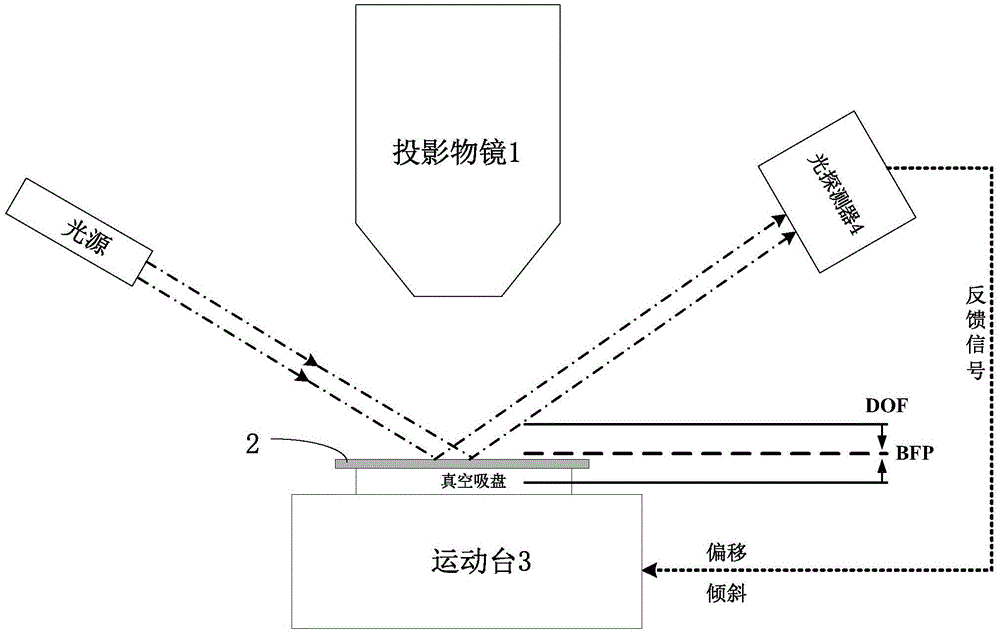

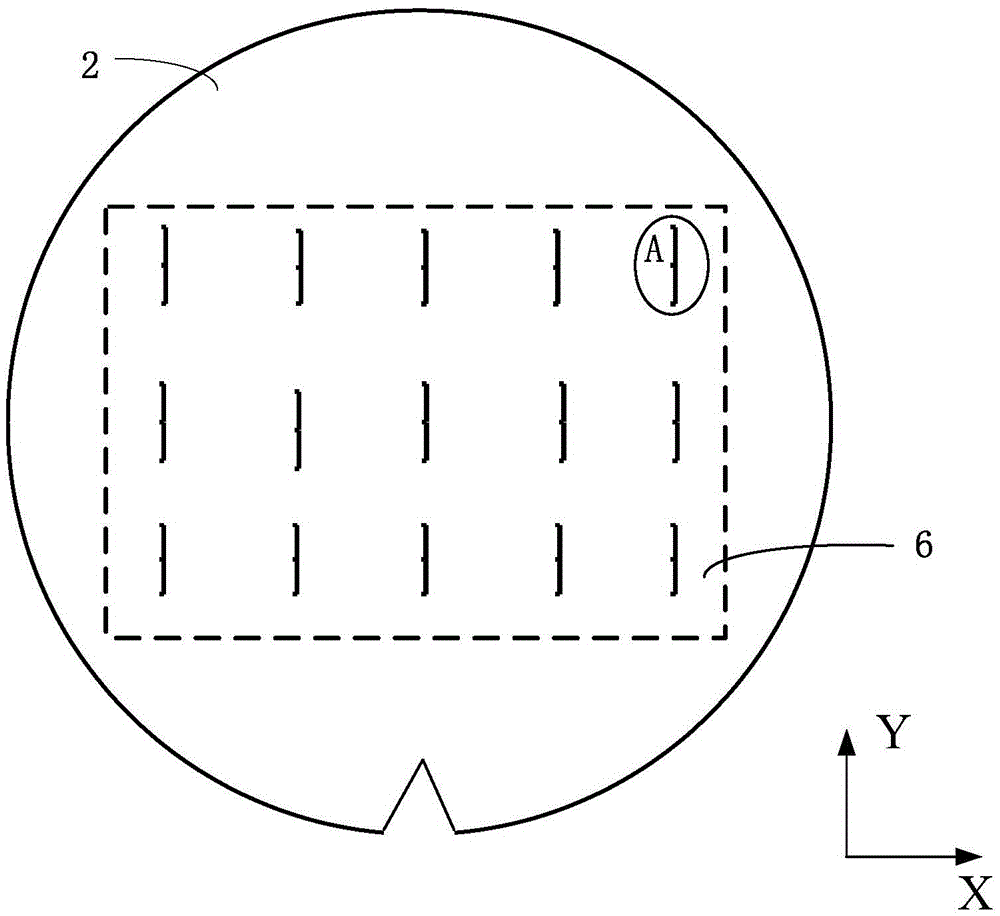

[0034] Such as image 3 As shown, this embodiment provides a focal plane detection device, including: a light source unit (not shown in the figure), an imaging unit, a focusing drive unit 109, a moving stage unit 107, and a control unit 110, wherein the light source unit It is used to irradiate the mask plate 101 to generate an imaging beam, and the mask plate 101 has a focusing pattern 101a; the imaging unit is used to image the focusing pattern 101a on the reflection device 108 and the focusing image sensor 106; The focusing drive unit 109 is used to vertically adjust the projection objective lens 104 to complete the focusing; the moving table unit 107 is provided with a reflecting device 108 with a reflecting mark 108a, which is used to move the reflecting device 108 horizontally and vertically The control unit 110 is used to analyze and process the graphic data collected by the focusing image sensor 106 , and to control the focusing drive unit 109 in feedback.

[0035] Sp...

Embodiment 2

[0055] Such as Figure 9 As shown, the focusing drive unit 109 in this embodiment adopts a vertical displacement adjustment platform with a vertical focusing function, and the control unit 110 is directly connected to the vertical displacement adjustment platform, and the output focusing control amount is directly The vertical displacement adjustment table is endowed, and the vertical displacement adjustment table is used as the actuator to complete the precise displacement action of the vertical position of the silicon wafer. In other words, the motion table unit 107 in this embodiment only moves the reflection device 108 horizontally.

Embodiment 3

[0057] Such as Figure 10 As shown, in this embodiment, a physical mask is used to replace the digital mask in Embodiment 1, and the physical mask is a transmissive or reflective mask 101, which is carried by the mask table 101b. The focusing pattern 101a on the physical mask is an IC integrated circuit process pattern to be exposed and developed, and this pattern can be analyzed and processed by a specific focusing algorithm and an image processing system of the control unit 110 .

[0058] In summary, the focal plane detection device of the present invention includes: a light source unit for irradiating the mask 101 to generate an imaging beam; an imaging unit for imaging the focusing pattern 101a on the mask 101 into a focusing image On the sensor 106; the focusing drive unit 109 is used to vertically adjust the projection objective lens 104 or the moving stage unit 107 to complete focusing; the moving stage unit 107 is provided with a reflective device 108 with a reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com