Folium isatidis non-tobacco cigarette and preparation method thereof

A Folium Folium, non-tobacco technology, applied in the field of cigarettes, can solve the problems of unstable product smell and taste and shelf life, poor smell of drug cigarettes, waste of Folium Folium resources, etc., to increase smoking safety and good mildew resistance , The effect of stabilizing the taste and smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

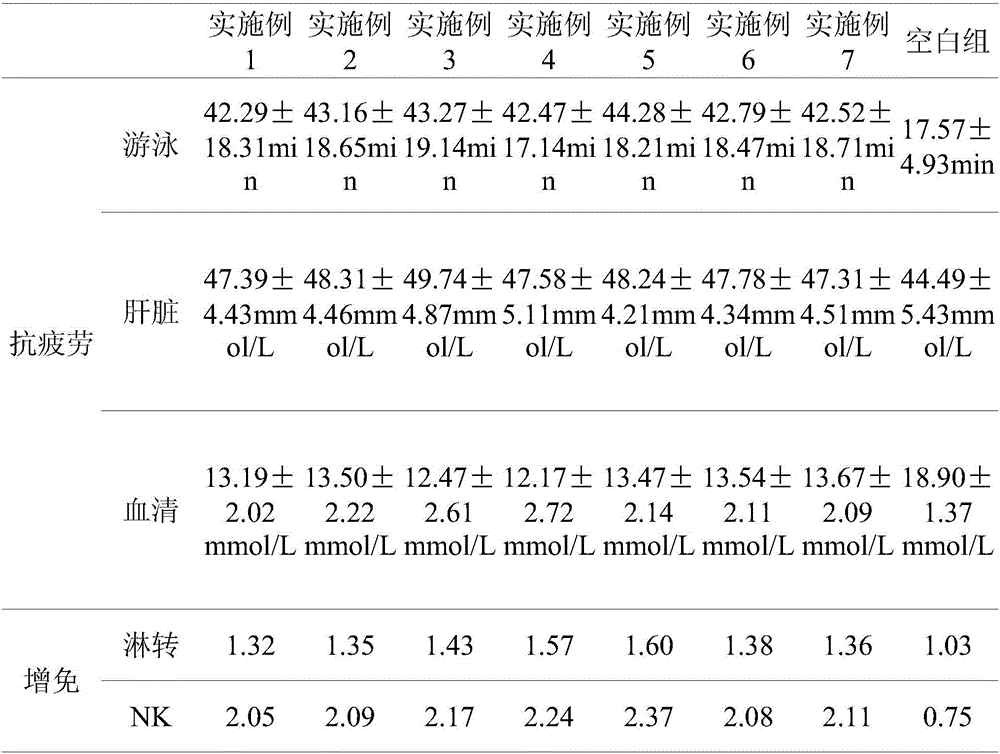

Examples

preparation example Construction

[0029] The preparation method of Daqingye non-tobacco cigarette, the steps are as follows:

[0030] Step 1. Take the big green leaves to remove moth-eaten and mildewed products, leave fresh big green leaves, wash them, and soak them in hydrogen-rich saline with a hydrogen concentration of 0.3-0.8mmol / L. 3 The Folium Folium soaked for more than 3min, preferably 3-6min, more preferably 5min, to obtain the Folium Folium after soaking;

[0031] Among them, if the hydrogen concentration of hydrogen-rich saline is lower than 0.3mmol / L and the time is lower than 3min, the oxygen free radical reaction of leaves cannot be effectively reduced, so that the damage of smoke to the respiratory tract cannot be effectively reduced. If it is higher than 0.8mmol / L, If the concentration is too high, it will affect the smell and taste of cigarettes.

[0032] Step 2: Heat the soaked Folium Folium at 40°C for 5min, then heat at 40°C-50°C for 5-15min, preferably 10min, then heat at 50°C-55°C for 3-...

Embodiment 1

[0041] The preparation method of Daqingye non-tobacco cigarette, the steps are as follows:

[0042] Step 1. Remove the moth-eaten and moldy products from the big green leaves, leave the fresh big green leaves, wash them, and soak them in hydrogen-rich saline with a hydrogen concentration of 0.3mmol / L. 3 The Folium Folium was soaked for 6 minutes to obtain the Folium Folium after soaking;

[0043] Step 2: heating the soaked Folium folium at 40°C for 5 minutes, then heating at 40°C for 15 minutes, then heating at 50°C for 8 minutes, then cooling down to room temperature, and drying with 2450 MHz microwave to obtain dried Folium folium;

[0044] Step 3: Moisturize the dried Folium folium until the water content is 13%, cut into shredded tobacco, add glucose oxidase powder, the mass ratio of glucose oxidase powder to shredded tobacco is 1.5:100, mix evenly to obtain shredded tobacco for cigarettes, and form cigarettes , get Daqingye non-tobacco cigarettes.

Embodiment 2

[0046] The preparation method of Daqingye non-tobacco cigarette, the steps are as follows:

[0047] Step 1. Remove the moth-eaten and moldy products from the big green leaves, leave the fresh big green leaves, wash them, and soak them in hydrogen-rich saline with a hydrogen concentration of 0.4mmol / L. 3 The Folium Folium was soaked for 8min to obtain the Folium Folium after soaking;

[0048] Step 2, heating the soaked Folium Folium at 40°C for 5 minutes, then heating at 40°C for 15 minutes, then heating at 50°C for 8 minutes, then cooling down to room temperature, and drying with 2200 MHz microwave to obtain dried Folium folium;

[0049] Step 3, remoisturize the dried Folium Folium until the water content is 15%, cut into shredded tobacco, add protamine powder, the mass ratio of protamine powder to shredded tobacco is 3:100, mix evenly, obtain shredded tobacco for cigarettes, and The shredded tobacco is irradiated with cobalt 60, and the irradiation dose is 5KGy, and then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com