Preparation method of TiO2/g-C3N4 composite visible-light photocatalyst

A visible light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of operator safety and hidden danger operation requirements, and achieve high photocatalytic degradation rate , simple process, and more photocatalytic active centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0035] This embodiment prepares TiO 2 / g -C 3 N 4 The method for composite visible light catalyst comprises the following steps:

[0036] ① Precursor preparation. 20mL Ti(OBu) 4 and 20g of melamine in 500mL of ethanol at 20°C were uniformly dispersed, and then added to the Ti(OBu) containing Ti(OBu) 4 Add 50 mL of water dropwise to ethanol containing melamine to obtain a mixed material; evaporate the mixed material to dryness in a water bath at 70° C. to 85° C. (80° C. in this embodiment) under stirring to obtain a precursor.

[0037] ② Transfer the precursor prepared in step ① to a muffle furnace, and calcinate it at 520 °C for 2 hours in the muffle furnace to obtain TiO 2 / g -C 3 N 4 Composite visible light catalyst.

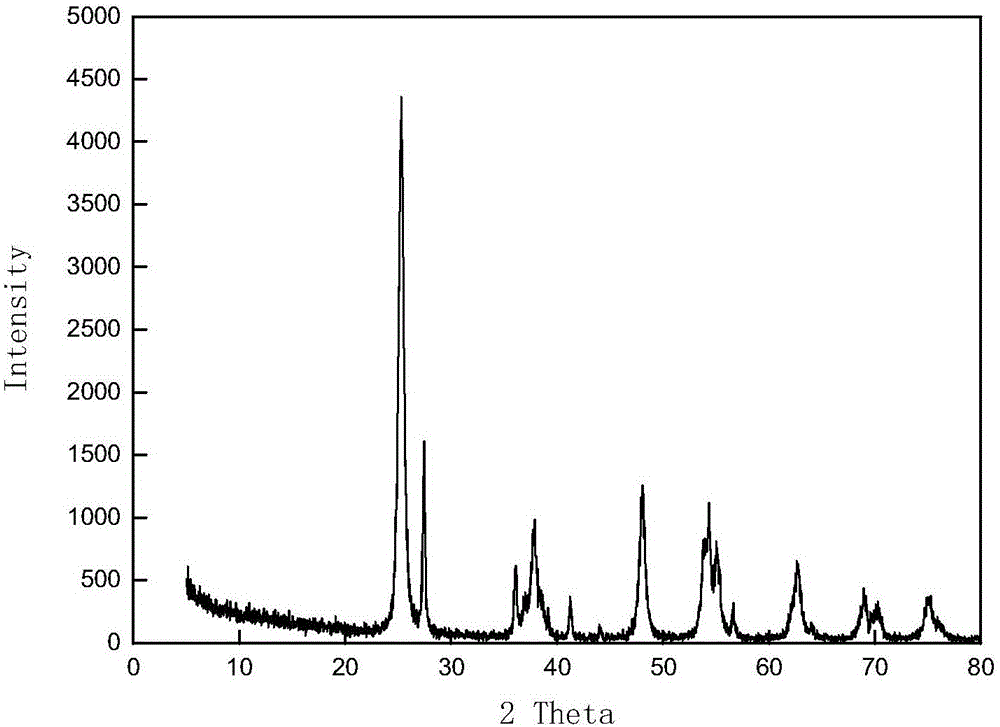

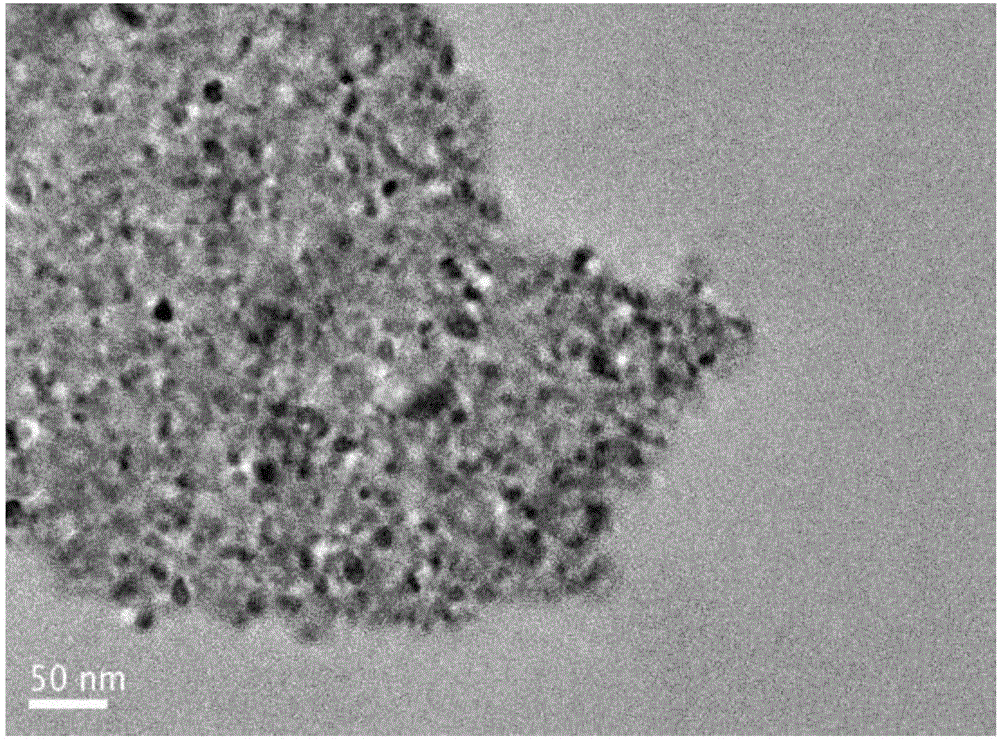

[0038] Characterize the product obtained in this embodiment: the transmission electron microscope (TEM) used for the characterization is the transmission electron microscope of the JEOL 2010 model of JEOL Corporation; the X-ray diffractometer is the X-...

Embodiment 2)

[0044] This embodiment prepares TiO 2 / g -C 3 N 4 The method all the other of composite visible photocatalyst is identical with embodiment 1, and difference is: step 1. in Ti(OBu) 4 The addition amount of the solution is 5mL, the temperature of ethanol is 25°C, and the temperature of the water bath is 85°C.

[0045] Detected by X-ray diffractometer, the product of the present embodiment is g-C 3 N 4 , Anatase TiO 2 and rutile TiO 2 The mixture of crystals shows that this embodiment has successfully produced TiO 2 / g -C 3 N 4 Composite visible light catalyst.

[0046] TiO prepared in this embodiment 2 / g -C 3 N 4 The TEM spectrum of the composite visible photocatalyst reveals nano-TiO 2 The particles are evenly distributed in the graphite flake g-C 3 N 4 middle.

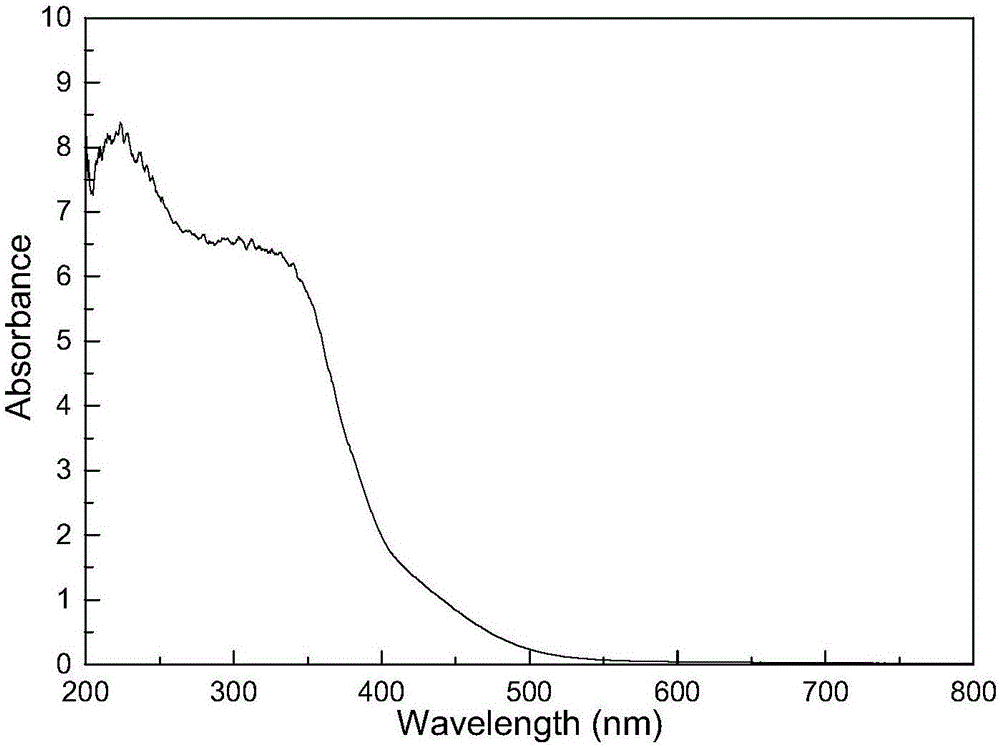

[0047] Detected by the ultraviolet-visible spectrometer, the TiO synthesized in this embodiment 2 / g -C 3 N 4 The visible light absorption region of the composite visible light catalyst is from 390 ...

Embodiment 3)

[0050] This embodiment prepares TiO 2 / g -C 3 N 4 The method all the other of composite visible photocatalyst is identical with embodiment 1, and difference is: step 1. in Ti(OBu) 4 The addition amount of water is 100mL, the dropwise addition amount of water is 1000mL, and the temperature of the water bath is 85°C.

[0051] Detected by X-ray diffractometer, the product of the present embodiment is g-C 3 N 4 , Anatase TiO 2 and rutile TiO 2 The mixture of crystals shows that this embodiment has successfully produced TiO 2 / g -C 3 N 4 Composite visible light catalyst.

[0052] TiO prepared in this embodiment 2 / g -C 3 N 4 The TEM spectrum of the composite visible photocatalyst reveals nano-TiO 2 The particles are evenly distributed in the graphite flake g-C 3 N 4 middle.

[0053] Detected by the ultraviolet-visible spectrometer, the TiO synthesized in this embodiment 2 / g -C 3 N 4 The visible light absorption region of the composite visible light catalyst is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com