Discharging rapid consolidation method and device for Ti cutting recycling and reproducing

A technology of recycling chips, which is applied in the field of metal material processing, can solve the problems of intensified oxidation of Ti chips, microstructure metallurgical defects, etc., and achieve short consolidation period, high consolidation pressure and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

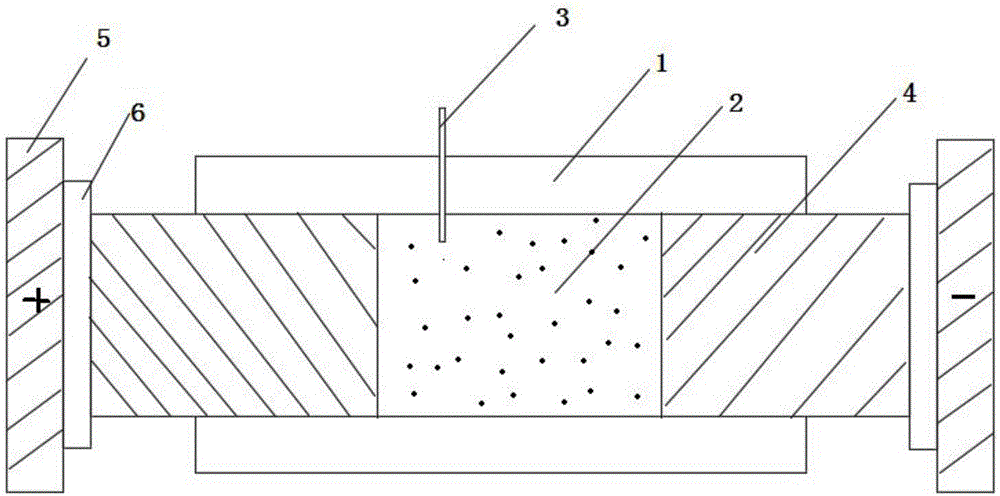

[0027] Such as figure 1 As shown, a kind of discharge rapid consolidation method of titanium swarf recycling remanufacturing that the present invention proposes, comprises the following steps:

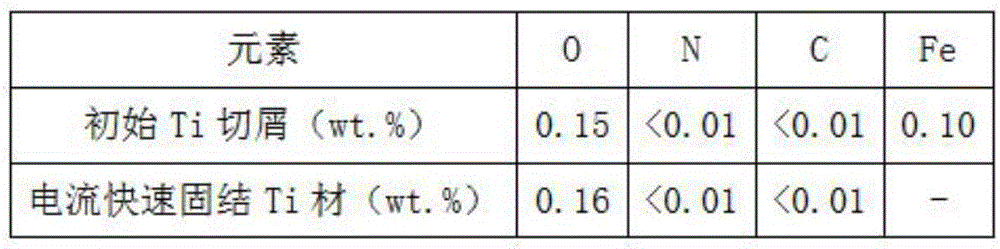

[0028] Step (1)-Ti cutting recovery pretreatment: use the chips generated by end milling Ti 2 (ASTM Grade 2) as raw materials, collect the chips, and use Inductively coupled plasma atomic emission spectroscopy (ICP for short) -AES) analyzes its chemical composition (mass percentage, wt.%), and analysis result is as follows: initial Ti cutting (mass percentage, wt.%) O=0.15, N<0.01, C<0.01, Fe=0.10; By analysis result It can be seen that the chemical composition (oxygen content) of the grade 2 Ti chips processed by milling meets the ASTM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com