Welding technique of compressor and liquid accumulator

A welding process and accumulator technology, applied in welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of refrigerant leakage from compressors, danger of flame welding, long time consumption, etc., to ensure welding effect, welding quality, welding high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

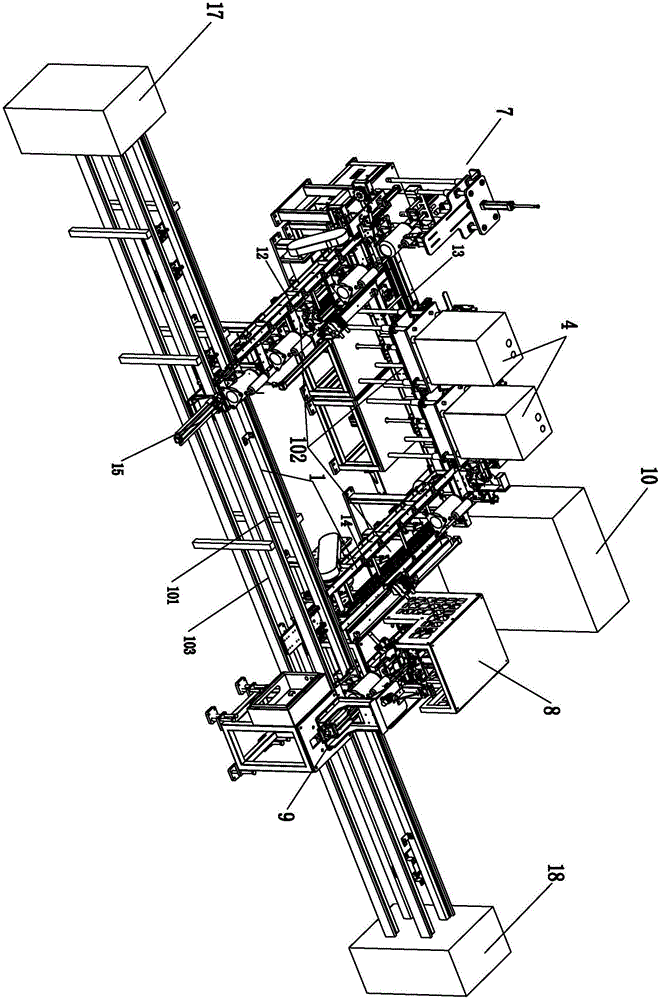

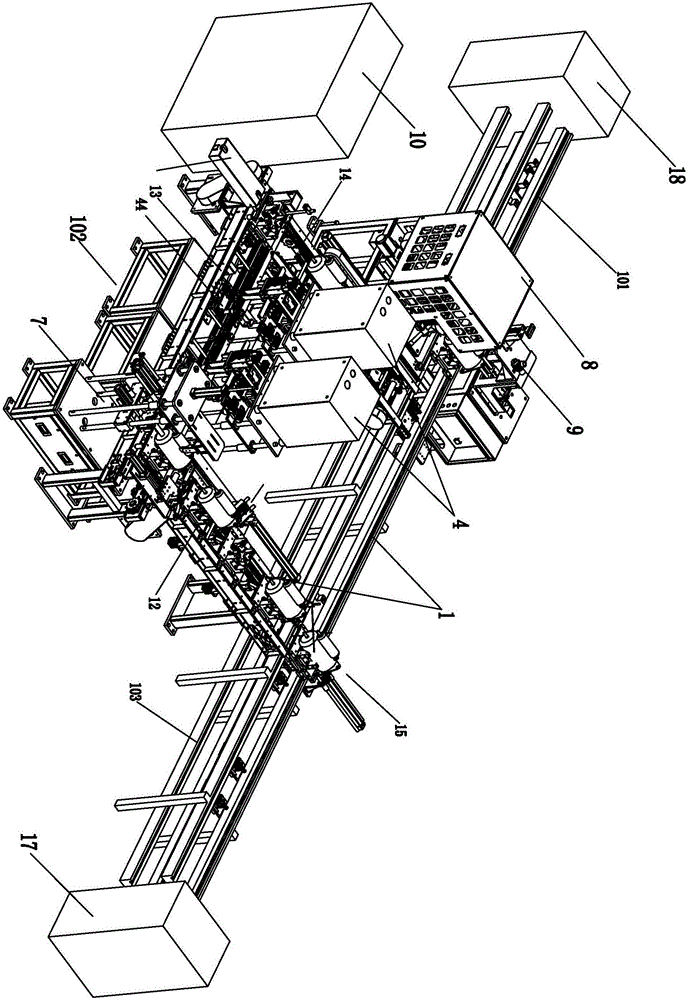

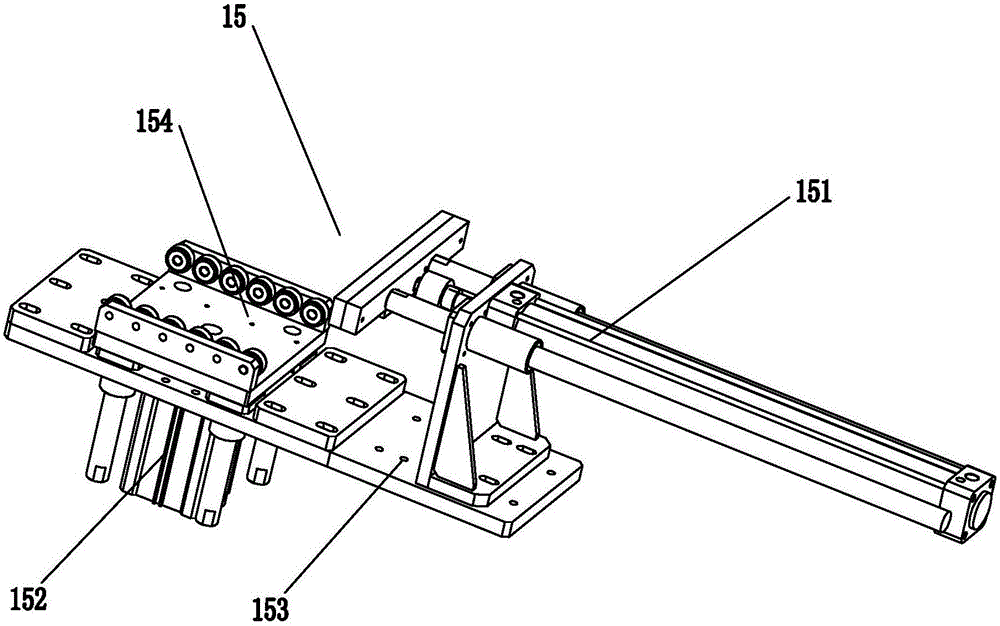

[0039] Embodiment one, see Figure 1 to Figure 19 As shown, a welding process method for a compressor and an accumulator is characterized in that it includes the following steps.

[0040] Step One: Install solder on the tube to be welded of the reservoir.

[0041] Step 2: Clean the reservoir with high-pressure air, the pressure of which is 0.1-1 MPa.

[0042] Step 3: Butt the pipe to be welded of the liquid accumulator with the pipe to be welded of the compressor, and at the same time place the liquid accumulator on the liquid accumulator bracket on the compressor for pre-fixation.

[0043] Step 4: Fill the interior of the liquid reservoir with nitrogen in advance, and the speed of nitrogen filling is 200-1000ML / S.

[0044] Step 5: Use the high-frequency brazing machine to position the liquid receiver and the compressor to ensure that the tubes to be welded of the liquid receiver and the compressor are aligned with the center of the high-frequency brazing coil. After positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com