Flux composition and solder paste

A technology of composition and flux, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems such as the reduction of insulation resistance of flux residues, and achieve the effect of suppressing the reduction of insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

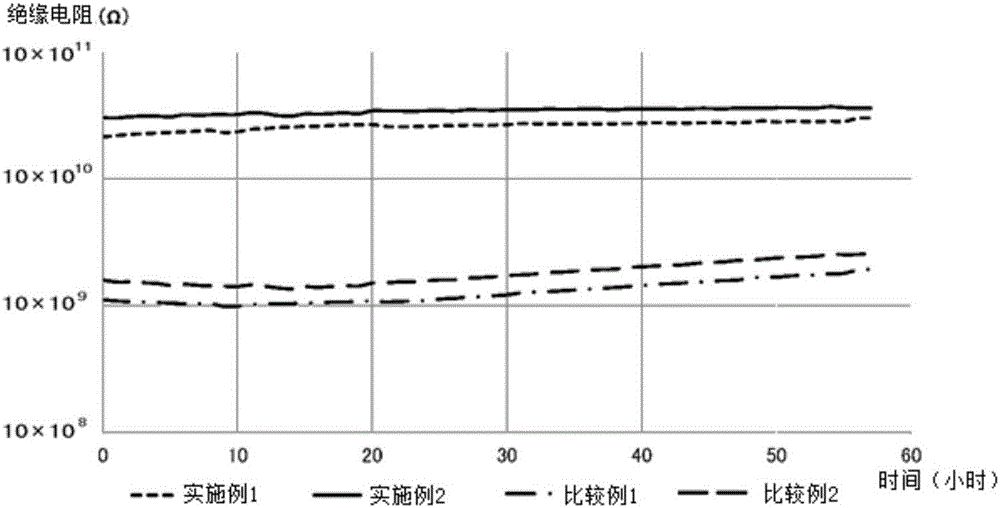

[0100] Hereinafter, the present invention will be described in detail with reference to Examples and Comparative Examples. In addition, this invention is not limited to these Examples.

[0101] Each component described in Table 1 was kneaded to obtain each flux composition. Then, 11.50% by weight of each of these flux compositions and 88.50% by weight of Sn-3Ag-0.5Cu solder alloy powder (average particle diameter: 28 μm) were mixed to prepare the respective solder pastes of Examples 1 and 2 and Comparative Examples 1 and 2. .

[0102] It should be noted that, unless otherwise specified, the numerical values described in Table 1 mean % by weight.

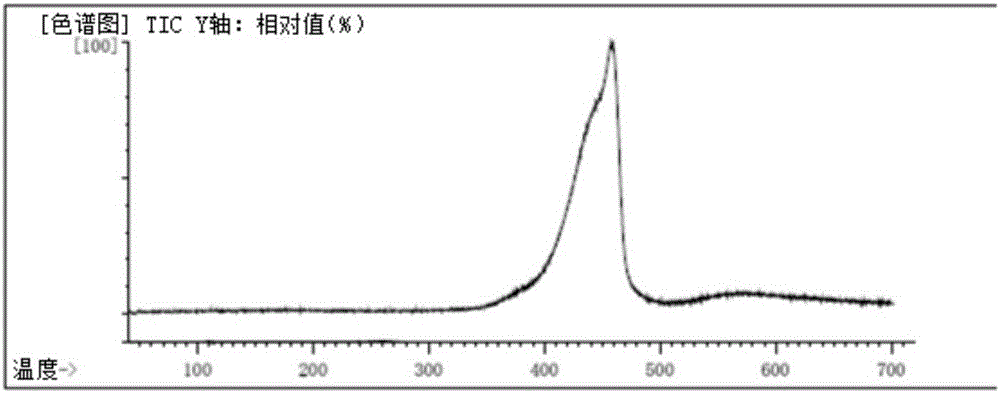

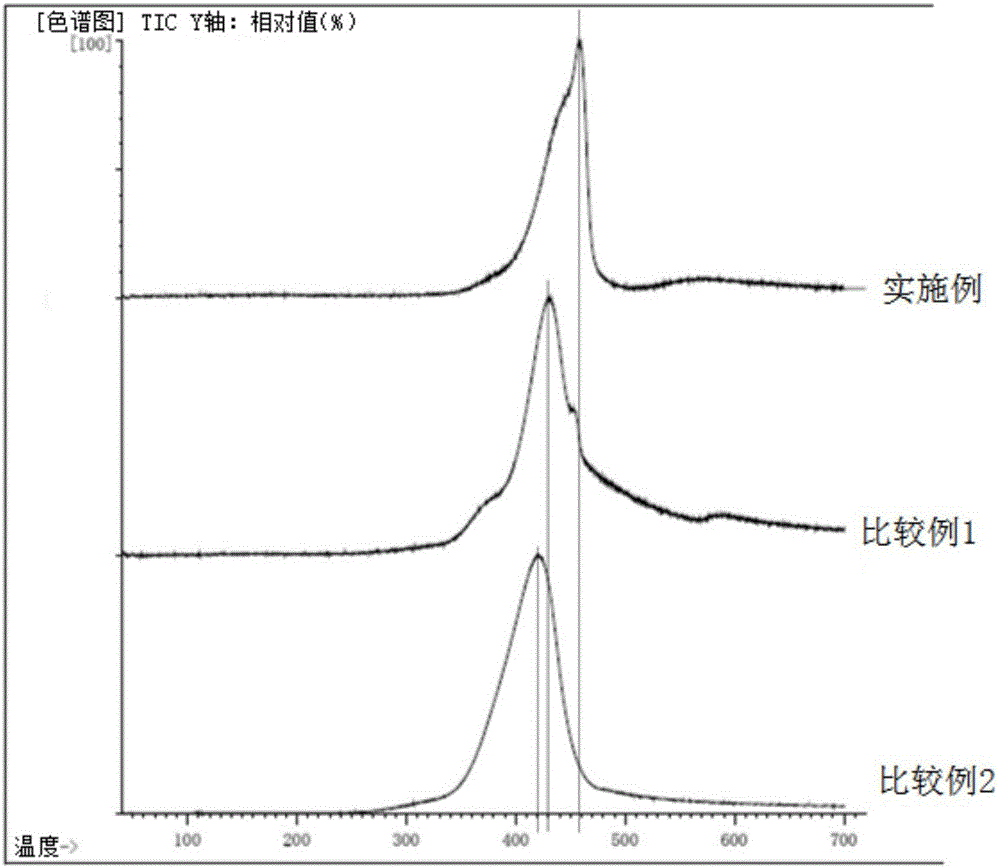

[0103] In addition, the thixotropic agents used in Examples (1 and 2) and Comparative Examples 1 and 2 were measured using pyrolysis gas chromatography mass spectrometry under the following measurement conditions. Its gas chromatogram is shown in figure 2 .

[0104] (sample)

[0105] 0.3mg

[0106] (pyrolysis)

[0107] Pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com