3D printer and printing method thereof

A 3D printer and printer technology, applied in the field of printing technology, can solve the problems that 3D printing technology cannot be realized, and achieve the effects of reducing initial setting time, reducing defects, and inhibiting fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

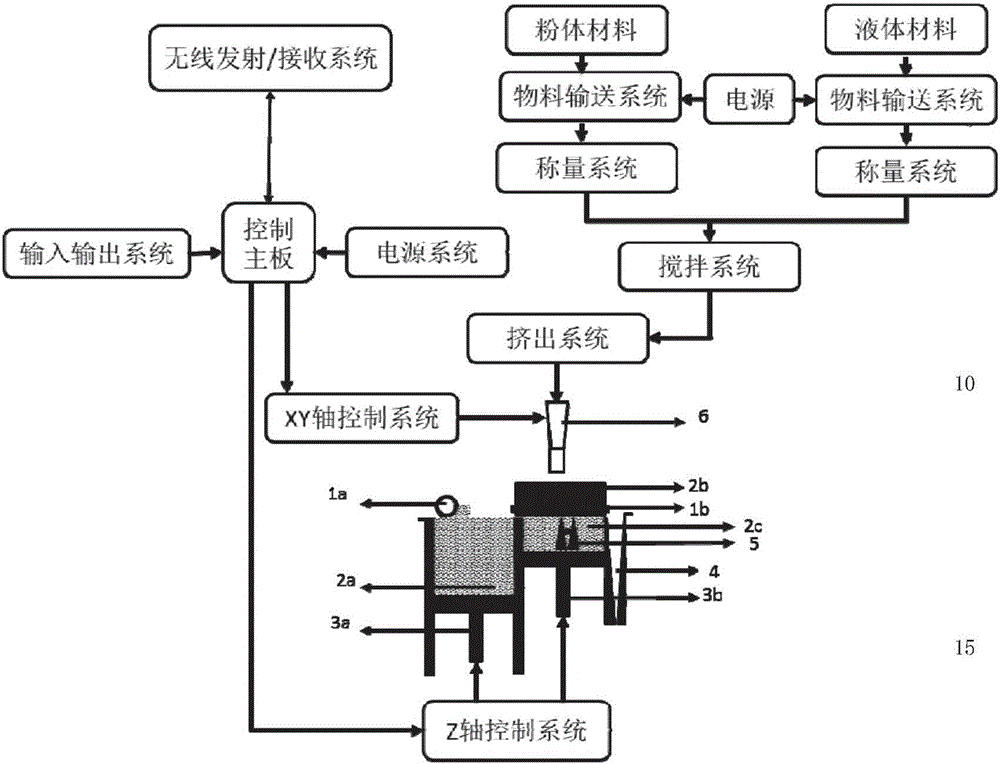

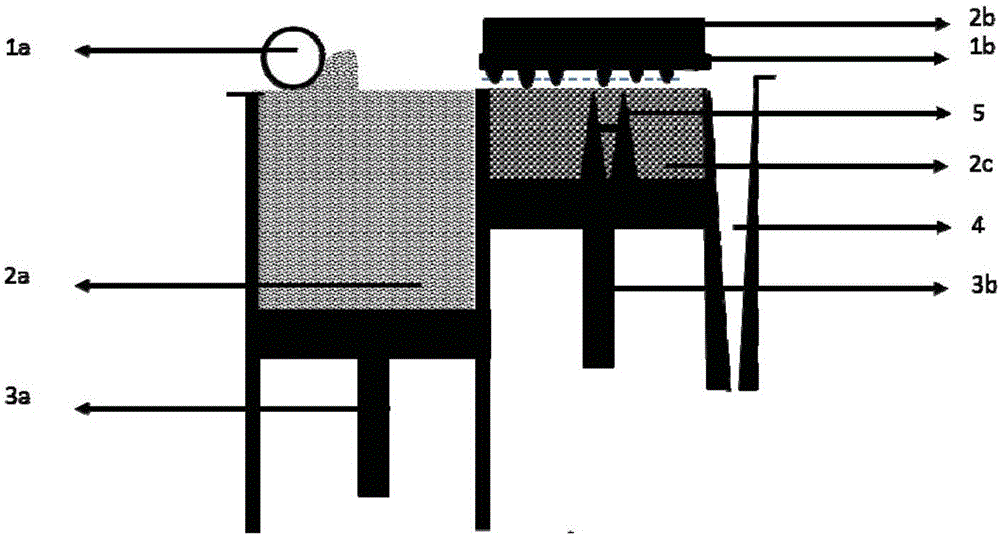

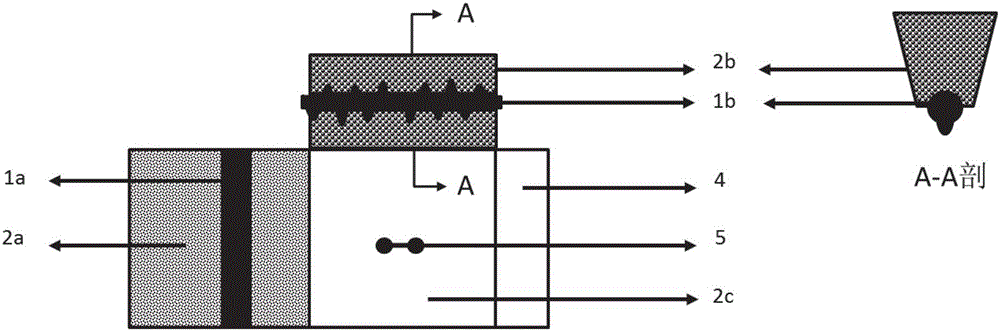

[0085] This embodiment provides a printing method of a 3D printer for cement-based materials. The 3D printer provided by this embodiment is as figure 1 As shown, the front view of the z-axis system of the 3D printer of the cement-based material in this embodiment is as figure 2 As shown, the top view of the z-axis system of the 3D printer of the cement-based material in this embodiment is as follows image 3 shown.

[0086] Step 1, through the mobile phone APP, use the wireless transmission / reception system to set the printing parameters.

[0087] The stirring time of the stirring system is 1min, the stirring rate is 90 rpm, the extrusion rate of the extrusion system is 3mm / s, the printing layer thickness is set to 1mm, the filling mode is grid filling, the filling density is 30%, the printing speed 70mm / s, idling speed 100mm / s. And transmit the corresponding parameter command to the corresponding system through the network, and then control the operation of the printer. ...

Embodiment 2

[0093] This embodiment provides a printing method of a 3D printer for cement-based materials.

[0094] Step 1, carry out the input and output system to set the printing parameters.

[0095] The stirring time of the stirring system is 2min, the stirring rate is 50 rpm, the extrusion rate of the extrusion system is 2mm / s, the printing layer thickness is set to 2mm, the filling mode is linear filling, the filling density is 20%, and the printing speed is 50mm / s, idling speed 80mm / s. The corresponding parameter command is transmitted to the corresponding system through the network, and then the operation of the printer is controlled.

[0096] Step 2, the powder spreading roller 1a evenly spreads the molding powder in the powder storage cylinder 2a on the second piston 3b of the molding cylinder in the molding cylinder 2c, and the excess molding powder falls into the powder collection cylinder 4, And can be reused. The printing nozzle 6 dips the uniformly mixed liquid material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com