Tapered corrugated extrusion die

A corrugated extrusion port technology, applied in the field of gradual corrugated extrusion dies, can solve the problem that the extrusion size of polymer materials is not easy to control, and achieve the effect of small internal stress, better mechanical properties and better mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

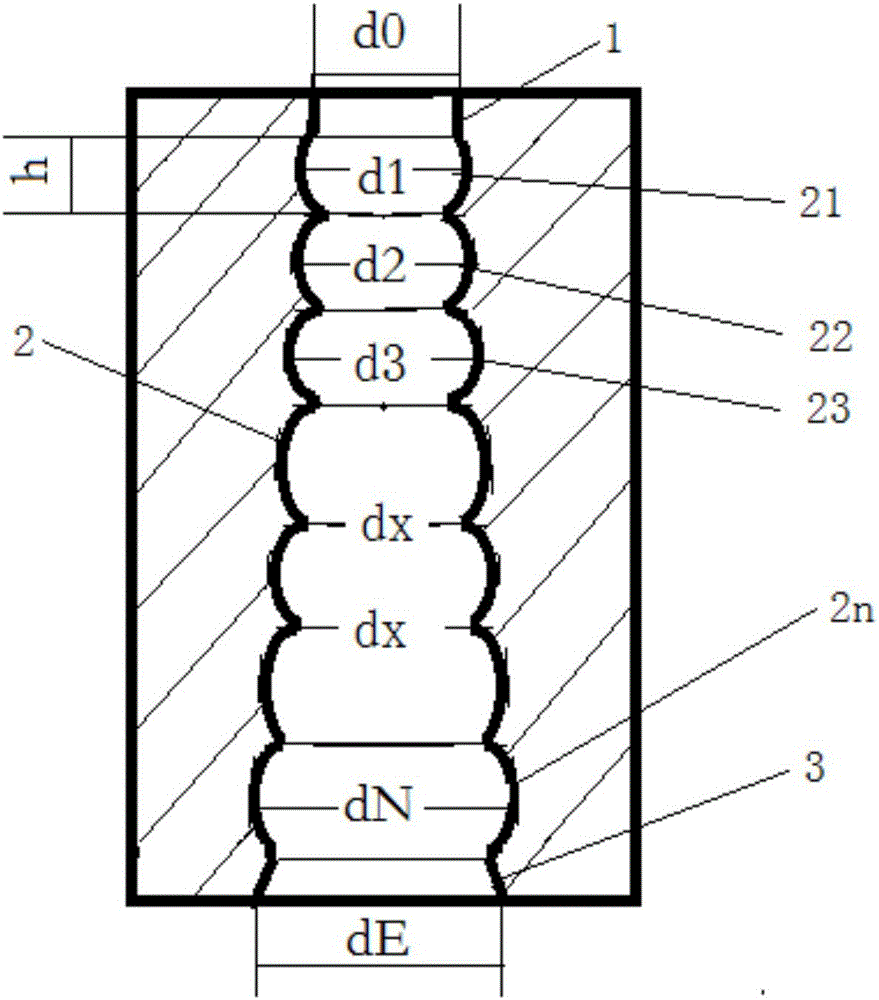

[0020] Such as figure 1 As shown, it is the best embodiment of the present invention, a gradual corrugated extrusion die, the die can be connected with the extruder, and can extrude rods, pipes, etc., and the inner wall of the die is basically in the shape of a similar bellows. The shape of the die is cylindrical, and there is a corrugated through hole on the central axis of the die. The corrugated through hole is the entrance area 1, the die area 2 and the exit area 3 from the entrance to the exit.

[0021] The entrance area 1 is cylindrical with a diameter of d0; the entrance area 1 is made into a cylinder to ensure the strength and rigidity of the die. If t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap