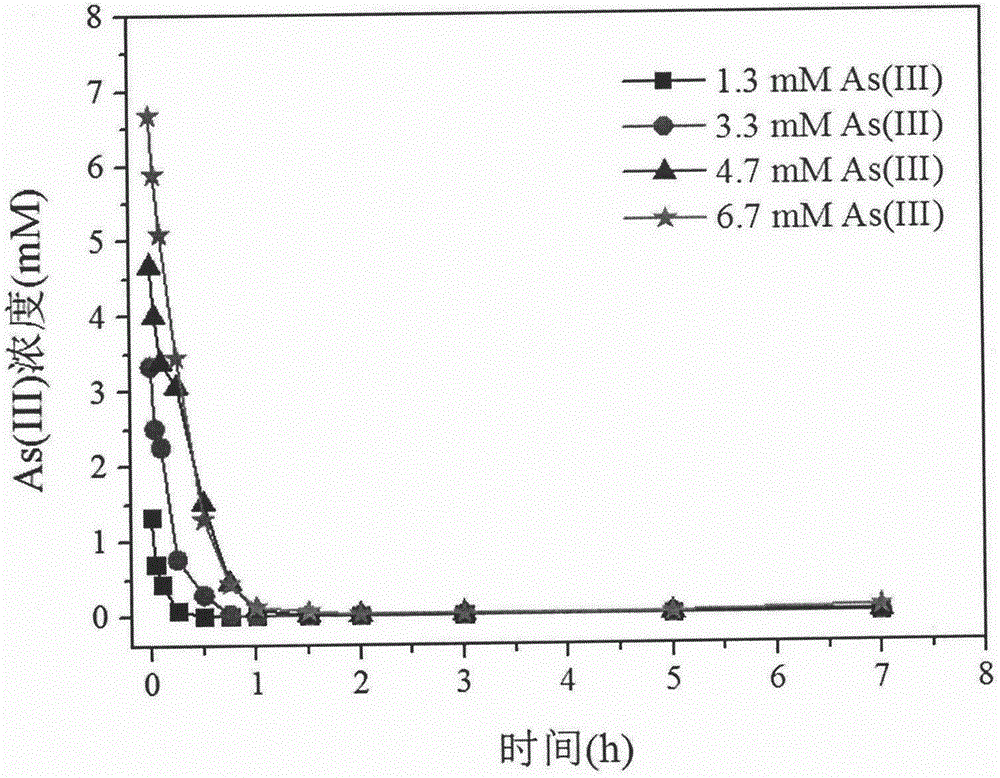

Method for removing high-concentration As (III) in water body through oxidation dissolution of ferrous sulfide (FeS)

A ferrous sulfide, high-concentration technology, applied in the direction of iron sulfide, chemical instruments and methods, oxidized water/sewage treatment, etc., to achieve good arsenic removal effect, arsenic removal effect and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The preparation process of FeS (except the centrifugation process) is carried out in an anaerobic glove box with an argon atmosphere, and the Pt catalyst can be used to make the oxygen concentration in the box less than 0.5ppm;

[0027] (2) The aqueous solution used for FeS synthesis preparation is all prepared with oxygen-free deionized water purged with high-purity nitrogen for half an hour;

[0028] (3) Weigh 28.33g FeCl 2 4H 2 O and 39.63 g Na 2 S·9H 2 O was sent into the glove box, and 250mL of 0.57M Fe(II) solution and 150mL of 1.1M S(-II) solution were prepared respectively with anaerobic water;

[0029] (4) Under the condition of moderate stirring, quickly pour the Fe(II) solution in step (3) into the S(-II) solution, so that the two are quickly and fully mixed to obtain a black suspension, and put it in gloves Stirring and aging in the box for three days;

[0030] (5) After three days, the suspension in step (4) was centrifuged at 10,000 rpm in a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com