Fully automatic industrial circulation cooling water purification and scale treatment system

A technology of circulating cooling water and treatment system, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve good flocculation and microfiltration functions, low cost, reduced hardness and conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

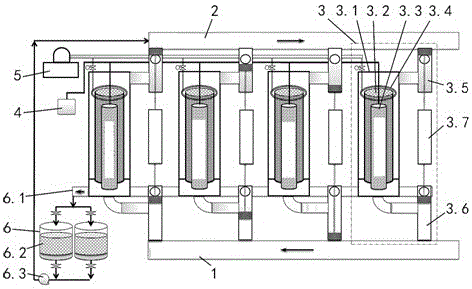

[0048] see figure 1 , the invention discloses a fully automatic industrial circulating cooling water purification and dirt treatment system. As shown in the figure: it includes the jellyfish inlet pipe 1, the jellyfish outlet pipe 2, the scale suction and filtration module 3, the electric control system 4, the high pressure gas system 5, and the sewage discharge system 6.

[0049] Wherein: the scale suction and filter module 3 includes: processor 3.1, scale suction and filter electrode 3.2, sterilizing and algae killing electrode 3.3, air distribution pipe 3.4, uplink tee 3.5, downlink tee 3.6, valve controller 3.7.

[0050] Wherein: sewage system 6 includes: sewage main pipe 6.1, sewage tank 6.2, drainage pump 6.3.

[0051] Between the inlet jellyfish pipe 1 and the jellyfish outlet pipe 2, several scale suction and filter modules 3 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com