Low-energy consumption urban sewage treatment system

A technology for urban sewage and treatment systems, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Clogging and other problems to achieve the effect of reducing energy consumption and carbon source demand, good denitrification and phosphorus removal, and preventing the loss of filter materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

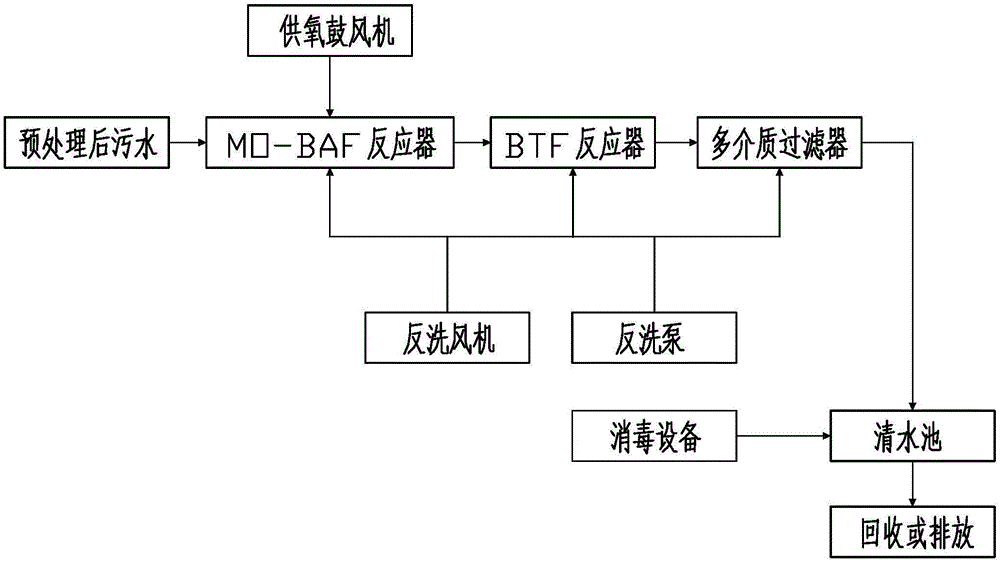

[0033] Such as figure 1 Shown, a kind of low-energy urban sewage treatment system of the present invention comprises the MO-BAF reactor, BTF reactor, multimedia filter and clear water tank connected successively by pipeline, described MO-BAF reactor, BTF reaction The device and the multimedia filter are all externally connected with a backwash pump and a backwash fan, and the MO-BAF reactor and the BTF reactor are all externally connected with an oxygen supply blower. The MO-BAF reactor is for applying micro-oxygen technology to BAF Composed of sewage treatment equipment. Disinfection equipment is also installed in the clear water pool or disinfectant is directly added.

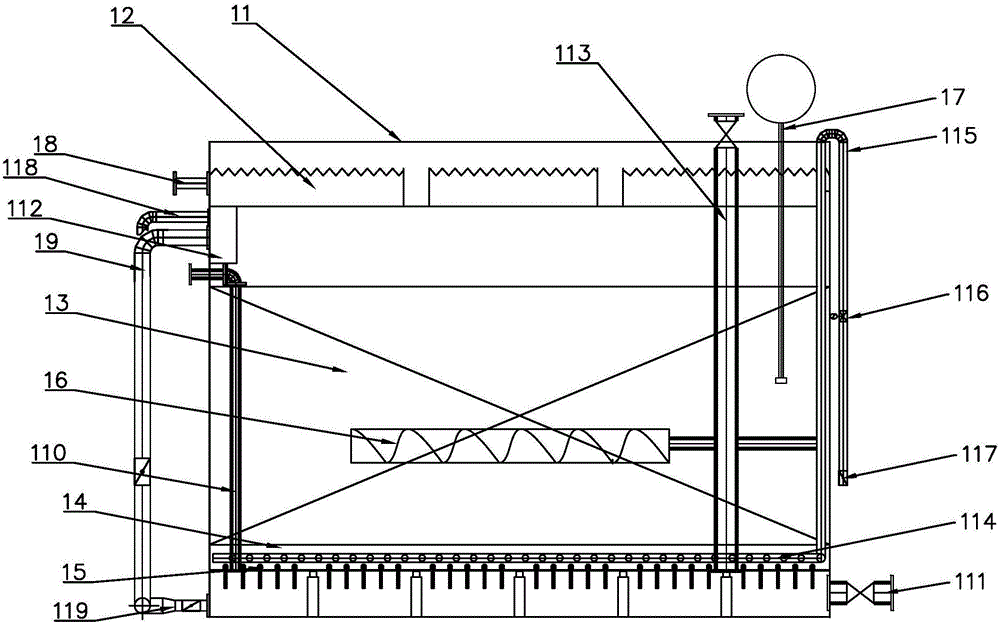

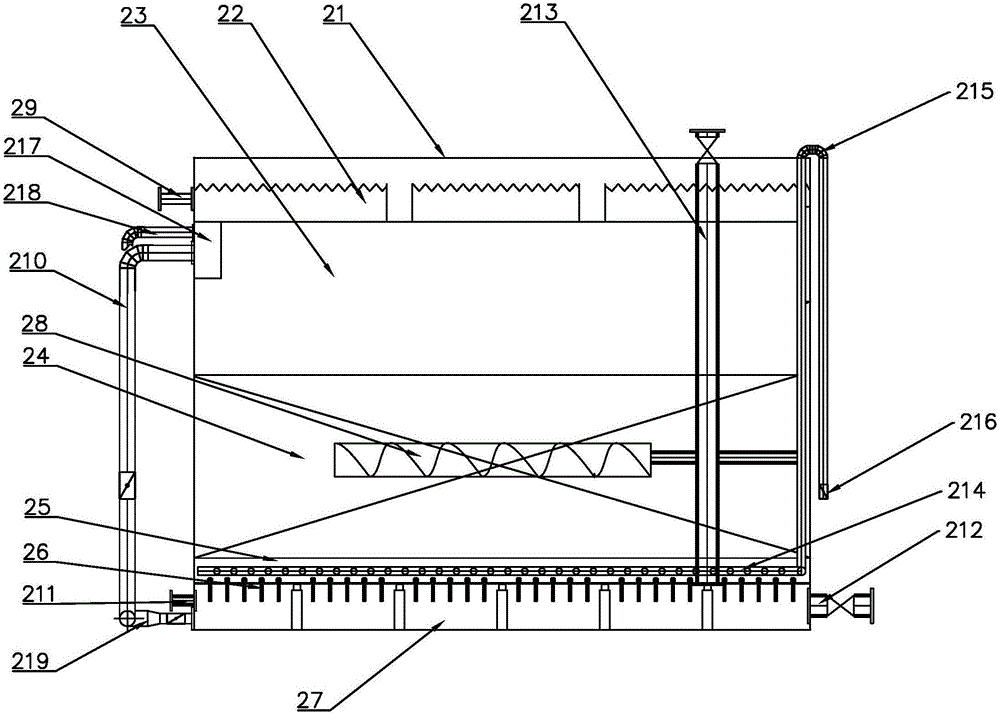

[0034] Such as figure 1As shown, the MO-BAF reactor includes a reaction tank body 11, and the reaction tank body 11 is sequentially provided with a water distribution system 12, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com