Normal-temperature curing type high-early-strength concrete and preparation method thereof

A concrete and early-strength technology, applied in the field of early-strength concrete and early-strength concrete cured at room temperature, can solve the problems of high energy consumption, poor later strength and durability, and low early-strength concrete of steam curing early-strength concrete, and avoid the problems of early-strength concrete. Excessive curing speed, excellent late strength and durability, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Concrete raw materials are taken according to the following proportions by weight: 100 parts of Portland cement, 20 parts of fly ash, 4 parts of silica fume, 8 parts of metakaolin, 220 parts of natural sand, 310 parts of gravel, and 0.7 parts of polycarboxylate superplasticizer part, 41 parts of mixing water. These raw materials are mixed according to a proper mixing method, and the early-strength concrete is obtained after mixing evenly. The early-strength concrete was prepared and cured at room temperature, and its compressive strength reached 16.5MPa in 10 hours, and the test showed that its compressive strength in 28 days reached 65.1MPa.

Embodiment 2-6

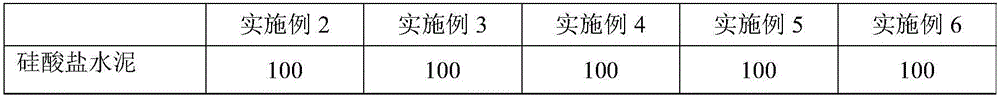

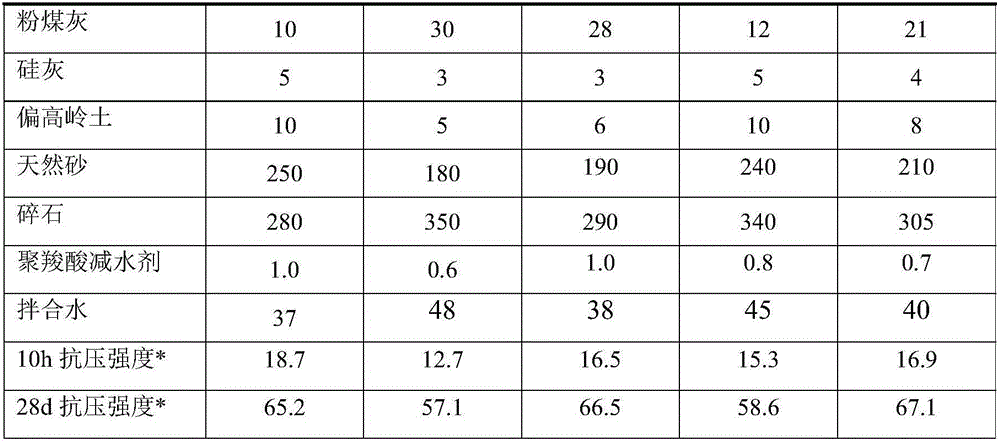

[0030] The early-strength concrete was prepared according to the same method as in Example 1, and the proportions by weight of the concrete raw materials used in the preparation process were shown in Table 1 below. The prepared concrete samples were prepared into squares, cured at room temperature, and the compressive strength of 10h and 28d was tested.

[0031] One of table 1 early-strength concrete formula ratio (unit: parts by weight)

[0032]

[0033]

[0034] *The unit of compressive strength is MPa.

[0035] It can be seen from Table 1 that the overall quality of concrete is better, and it can basically reach the demoulding strength requirement of 15Mpa in 10 hours, which has important application significance for the environment that requires the properties of early strength and super early strength of concrete.

Embodiment 7-11

[0037] Weigh the raw materials according to the ratio of raw materials recorded in Table 2, and mix Portland cement, fly ash, silica fume and high-grade soil under the condition of 15°C to 35°C, and stir evenly. Then, add natural sand and gravel to the mixture of cementitious materials and stir for 8-120 seconds. Finally, mix the polycarboxylate water reducer and tap water and add it into the mixture mixed with sand and gravel, stir for 90-180 seconds, preferably 90-150 seconds, stop, and get the early-strength concrete. The early-strength concrete was made into a square, cured at room temperature, and its 10h and 28d compressive strength was tested.

[0038] Two (weight parts) of early-strength concrete formula ratio of table 2

[0039] Example 7 Example 8 Example 9 Example 10 Example 11 Portland cement 100 100 100 100 100 fly ash 29 15 22 23 19 Silica fume 4 4 3 4 5 Metakaolin 7 9 8 9 8 natural sand 200 240 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com