A kind of soft magnetic ferrite material with high frequency, low loss and high saturation magnetic flux density and its preparation method

A soft ferrite and magnetic flux density technology, applied in the direction of inorganic material magnetism, etc., can solve the problem of not improving the saturation magnetic flux density characteristics, and achieve the effect of optimizing the sintering process and high magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

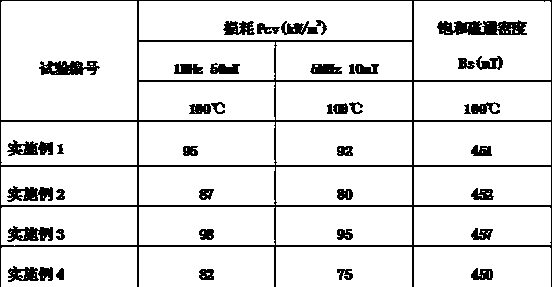

Embodiment 1

[0018] Embodiment 1: A high-frequency, low-loss, high-saturation magnetic flux density soft ferrite material, composed of a main component and a sub-component, the main component is a quaternary system, respectively Fe 2 O 3 : 54.96mol%, ZnO: 5.66mol%, Co 2 O 3 :0.10mol%, the rest is MnO; secondary component Nb 2 O 5 :0.02wt%, CaCO 3 :0.10wt%, V 2 O 5 :0.03wt%, ZrO 2 : 0.01wt%, the above auxiliary components are as Fe 2 O 3 , ZnO, MnO, Co 2 O 3 The total weight percentage is calculated.

[0019] A method for preparing the high-frequency, low-loss, high-saturation magnetic flux density soft ferrite material described in Example 1, including the following steps:

[0020] 1) Ingredients: adopt quaternary formula, follow the main formula Fe 2 O 3 , ZnO, Co 2 O 3 The ratio of MnO and MnO is weighed and mixed with sanding, and the sanding time is 15min;

[0021] 2) Pre-burning: pre-burn the mixed powder, the pre-burning temperature is 850℃, and the heat preservation is 2h;

[0022] 3) Sand ...

Embodiment 2

[0027] Embodiment 2: A high-frequency, low-loss, high-saturation magnetic flux density soft ferrite material, composed of a main component and a secondary component, the main component is a quaternary system, respectively Fe 2 O 3 :55.36mol%, ZnO: 4.00mol%, Co 2 O 3 :0.20mol%, the rest is MnO; secondary component Nb 2 O 5 :0.02wt%, CaCO 3 :0.05wt%, V 2 O 5 :0.03wt%, ZrO 2 : 0.01wt%, the above auxiliary components are as Fe 2 O 3 , ZnO, MnO, Co 2 O 3 The total weight percentage is calculated.

[0028] A method for preparing the high-frequency, low-loss, high-saturation magnetic flux density soft ferrite material described in Example 2, including the following steps:

[0029] 1) Ingredients: adopt quaternary formula, follow the main formula Fe 2 O 3 , ZnO, Co 2 O 3 The ratio of MnO and MnO is weighed and sanded, and the sanding time is 20min;

[0030] 2) Pre-burning: pre-burning the mixed powder, the pre-burning temperature is 900℃, and the heat preservation is 2h;

[0031] 3) Sand mill...

Embodiment 3

[0036] Embodiment 3: A high-frequency, low-loss, high-saturation magnetic flux density soft ferrite material, consisting of a main component and a sub-component, the main component is a quaternary system, respectively Fe 2 O 3 :55.40mol%, ZnO: 3.77mol%, Co 2 O 3 :0.20mol%, the rest is MnO; secondary component Nb 2 O 5 :0.02wt%, CaCO 3 :0.10wt%, V 2 O 5 :0.03wt%, Ta 2 O 5 :0.03wt%, the above auxiliary components are as Fe 2 O 3 , ZnO, MnO, Co 2 O 3 The total weight percentage is calculated.

[0037] A method for preparing the high-frequency, low-loss, high-saturation magnetic flux density soft ferrite material described in Example 3 includes the following steps:

[0038] 1) Ingredients: adopt quaternary formula, follow the main formula Fe 2 O 3 , ZnO, Co 2 O 3 The ratio of MnO and MnO is weighed and mixed with sanding, and the sanding time is 15min;

[0039] 2) Pre-burning: pre-burning the mixed powder, the pre-burning temperature is 750℃, and the heat preservation is 2h;

[0040] 3) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com