Surgical dressing material with cooling property and preparation method of surgical dressing material

A technology with ability and any proportion, applied in the field of medical dressing materials and its preparation, can solve the problems of alleviating the pain of patients, and there is no way to reduce the temperature of the wound site and surroundings, so as to achieve the effects of pain relief, shortening the recovery time, and reducing the temperature of the wound surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

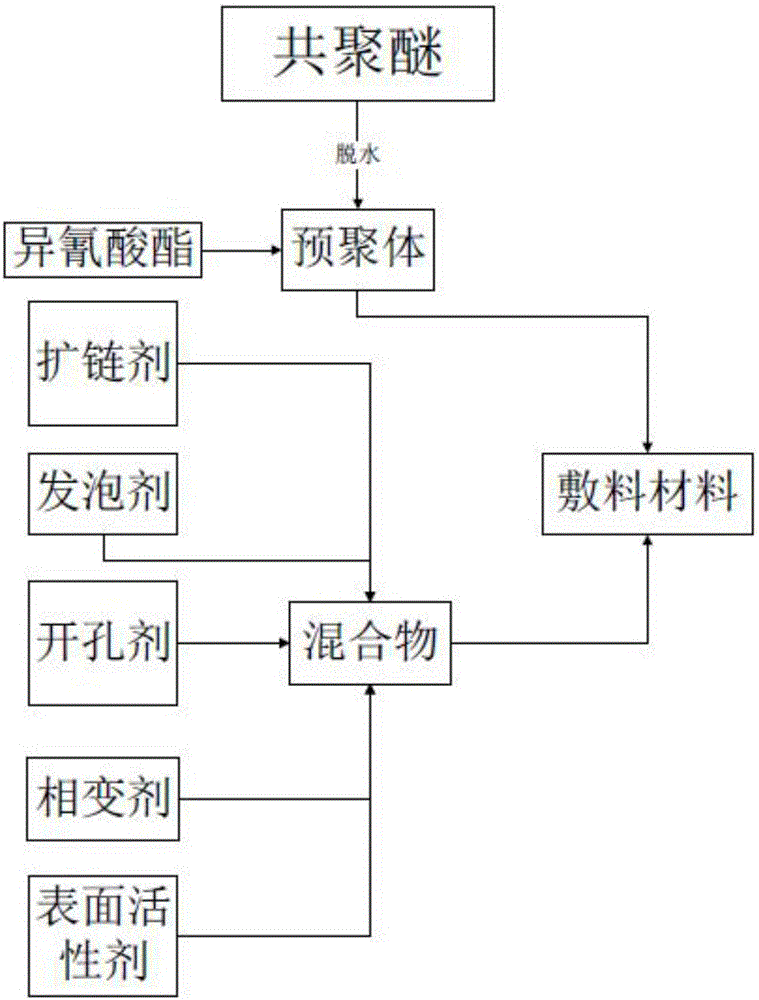

[0033] like figure 1 Shown, there is the preparation method of the medical dressing material of cooling ability, comprises the steps:

[0034] Step 1. Weigh the copolyether according to the proportion by weight, and vacuum dehydrate the copolyether at 70-130° C. for 60-300 minutes. Preferably, the dehydration temperature is 130° C. and the dehydration time is 120 minutes.

[0035] Step 2: Weigh the isocyanate according to the proportion by weight and add it to the dehydrated copolyether in step 1, and react under vacuum at 50-80°C for 50-100min, preferably at a reaction temperature of 70°C, to obtain a prepolymer.

[0036] Step 3: Weighing the chain extender, foaming agent, surfactant, cell opening agent and deformation agent according to the proportion by weight, and fully mixing to obtain a uniform mixture.

[0037] Step 4: Mix the prepolymer with the mixture, pour into a mold preheated to 30-50°C, pressurize and vulcanize for 5-30min, cool, demould, and cut to obtain a dre...

Embodiment 1

[0040] Medical dressing material with cooling ability: by 65 parts by weight of copolyether, 20 parts by weight of isocyanate, 30 parts by weight of chain extender, 40 parts by weight of foaming agent, 2 parts by weight of surfactant, 3 parts by weight of cell opening agent and 20 parts by weight of Part phase change agent composition.

[0041] The preparation method of the above-mentioned medical dressing material with cooling ability: firstly weigh the copolyether according to the proportion by weight, and vacuum dehydrate the copolyether at 100° C. for 80 minutes. The isocyanate was weighed in proportion by weight and added to the dehydrated copolyether in step 1, and reacted at 50° C. for 100 minutes under vacuum to obtain a prepolymer. The chain extender, the foaming agent, the surfactant, the cell opener and the deformation agent are weighed according to the proportion by weight, and fully mixed to obtain a uniform mixture. Mix the prepolymer with the mixture, pour it i...

Embodiment 2

[0045] Medical dressing material with cooling ability: by 85 parts by weight of copolyether, 10 parts by weight of isocyanate, 40 parts by weight of chain extender, 60 parts by weight of foaming agent, 5 parts by weight of surfactant, 1 part by weight of cell opener and 35 parts by weight of Part phase change agent composition.

[0046] The preparation method of the above-mentioned medical dressing material with cooling ability: firstly weigh the copolyether according to the proportion by weight, and vacuum dehydrate the copolyether at 70° C. for 300 min. The isocyanate was weighed in proportion by weight and added to the dehydrated copolyether in step 1, and reacted at 80° C. for 60 minutes under vacuum to obtain a prepolymer. The chain extender, the foaming agent, the surfactant, the cell opener and the deformation agent are weighed according to the proportion by weight, and fully mixed to obtain a uniform mixture. Mix the prepolymer with the mixture, pour it into a mold pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com