Method for preparing aerogel

An aerogel and hydrogel technology, applied in the field of preparation of β-cyclodextrin-based polymer aerogels, can solve problems such as few reports, and achieve the effects of low cost, flexible and simple process, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

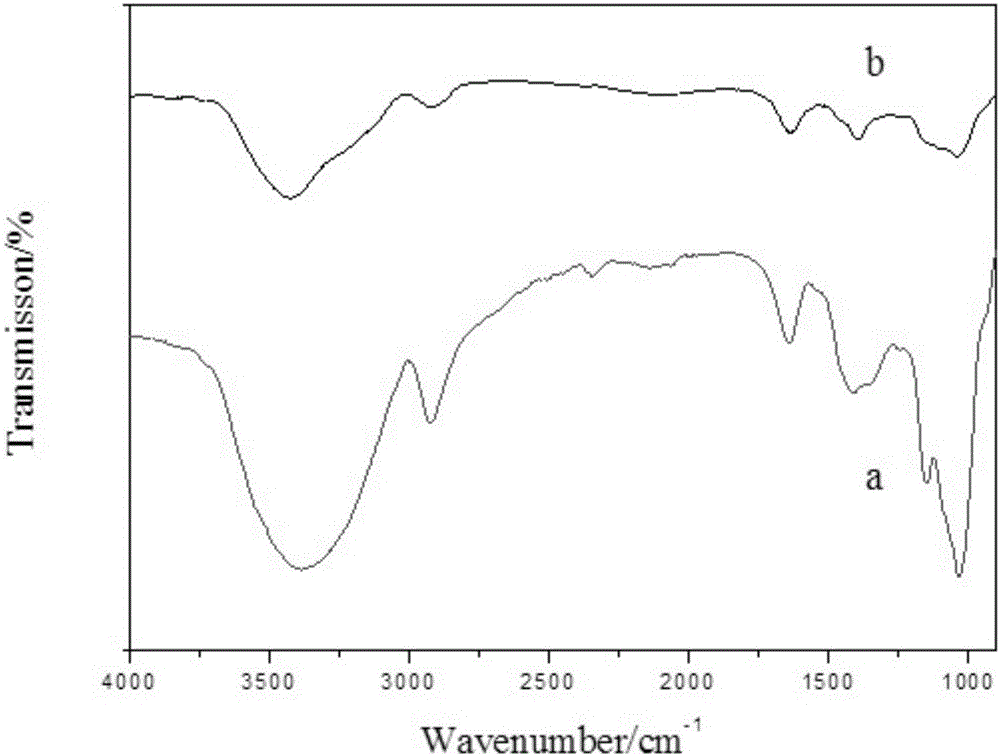

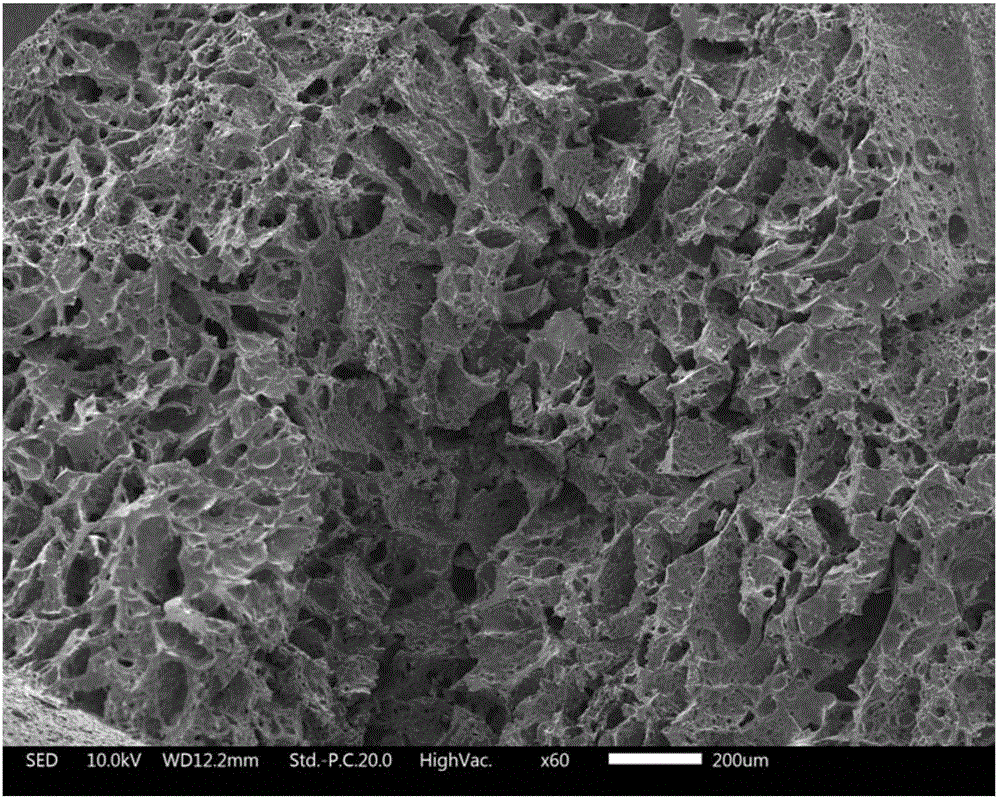

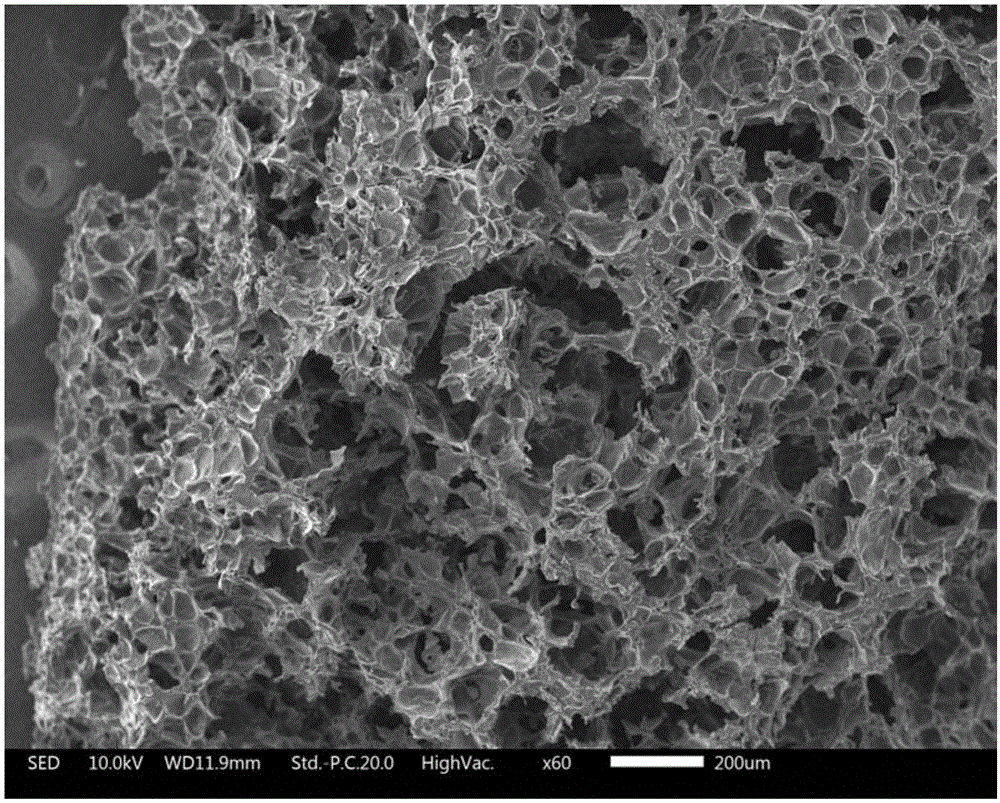

[0029] (1) An appropriate amount of β-cyclodextrin was completely dissolved in deionized water at 90°C, recrystallized twice, and then dried at 105°C to constant weight.

[0030] (2) Weigh 2 g of recrystallized and dried β-cyclodextrin, and simultaneously weigh an appropriate amount of epichlorohydrin, sodium hydroxide and polyethylene glycol in proportion. Add β-cyclodextrin into the sodium hydroxide solution, stir magnetically at 55-60°C until completely dissolved; then add polyethylene glycol into the solution, stir magnetically at 55-60°C until completely dissolved; finally Add epichlorohydrin dropwise, and stir magnetically at 55-60° C. until a hydrogel is formed. In the above solution system, the ratio of the amount of glucose units of β-cyclodextrin to the amount of epichlorohydrin is 1:1, the ratio of the amount of matter of polyethylene glycol to β-cyclodextrin is 1:3, The ratio of epichlorohydrin to sodium hydroxide is 1:1, the molecular weight of polyethylene glyco...

Embodiment 2

[0034] In this example, the molecular weight of polyethylene glycol is 1000; the ratio of the glucose unit of β-cyclodextrin to the amount of epichlorohydrin is 1:2; the rest of the treatment is the same as that of Example 1.

Embodiment 3

[0036] In this embodiment, the ratio of the amount of substances of β-cyclodextrin glucose unit to epichlorohydrin is 1:2; the ratio of the amount of substances of polyethylene glycol to β-cyclodextrin is 1:4; the rest The processing is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com