Cold storage material with phase transformation point between 2 DEG C and 8 DEG C and preparation method thereof

A technology of cold storage material and phase transition point, applied in the field of chemistry, can solve the problems of lack of cold storage material, easy overcooling of biological products, etc., and achieve the effects of simple process, large latent heat of evaporation, and good cold storage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with specific embodiments.

[0023] 1. Preparation of Liquid A

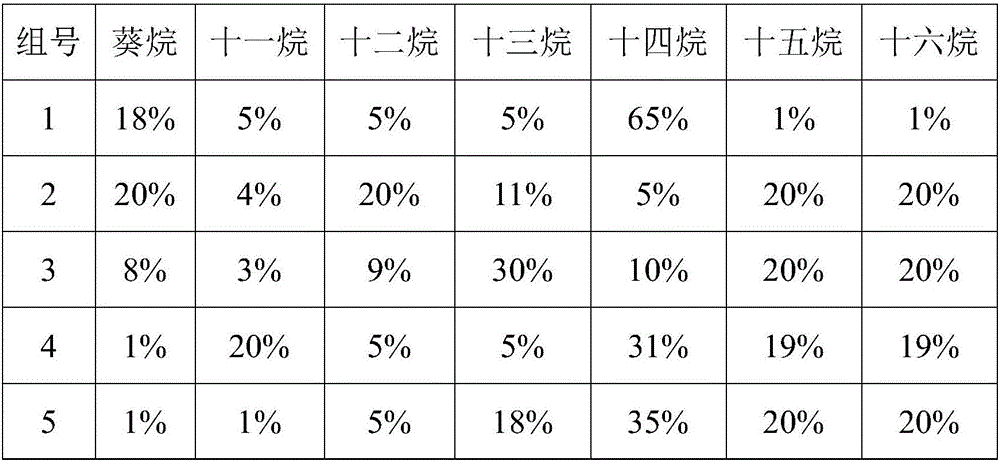

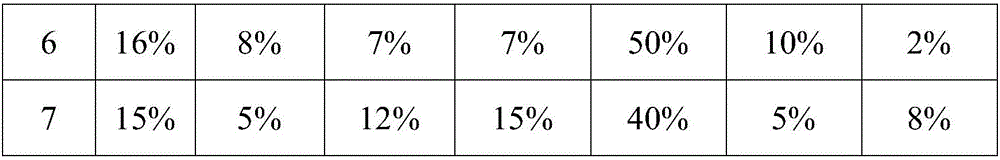

[0024] See Table 1 for the components prepared for preparing Liquid A in volume percentage.

[0025] Table 1 is used to prepare each component of liquid A and proportioning ratio

[0026]

[0027]

[0028] Preparation method: Mix decane, undecane, dodecane, tridecane, tetradecane, pentadecane and hexadecane at room temperature, and stir for 10 minutes to obtain liquid A.

[0029] Decane, undecane, dodecane, tridecane, tetradecane, pentadecane, and hexadecane are homologues that have similar, but not identical, physical and chemical properties. The liquid A composed of these homologues provides necessary reaction sites and material basis for the chemical reactions involved in the post-production process of cold storage materials. At the same time, they are also an important part of cold storage materials.

[0030] 2. Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com