Method for recycle gas condensation and liquid nitrogen separation of synthesis ammonia

A technology of condensation separation and circulating gas, which is applied in the directions of refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems that the ammonia ice machine refrigeration technology cannot satisfy the condensation of circulating gas and separation of liquid ammonia, and achieve good chemical stability and safety. The effect of large cooling capacity and small compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

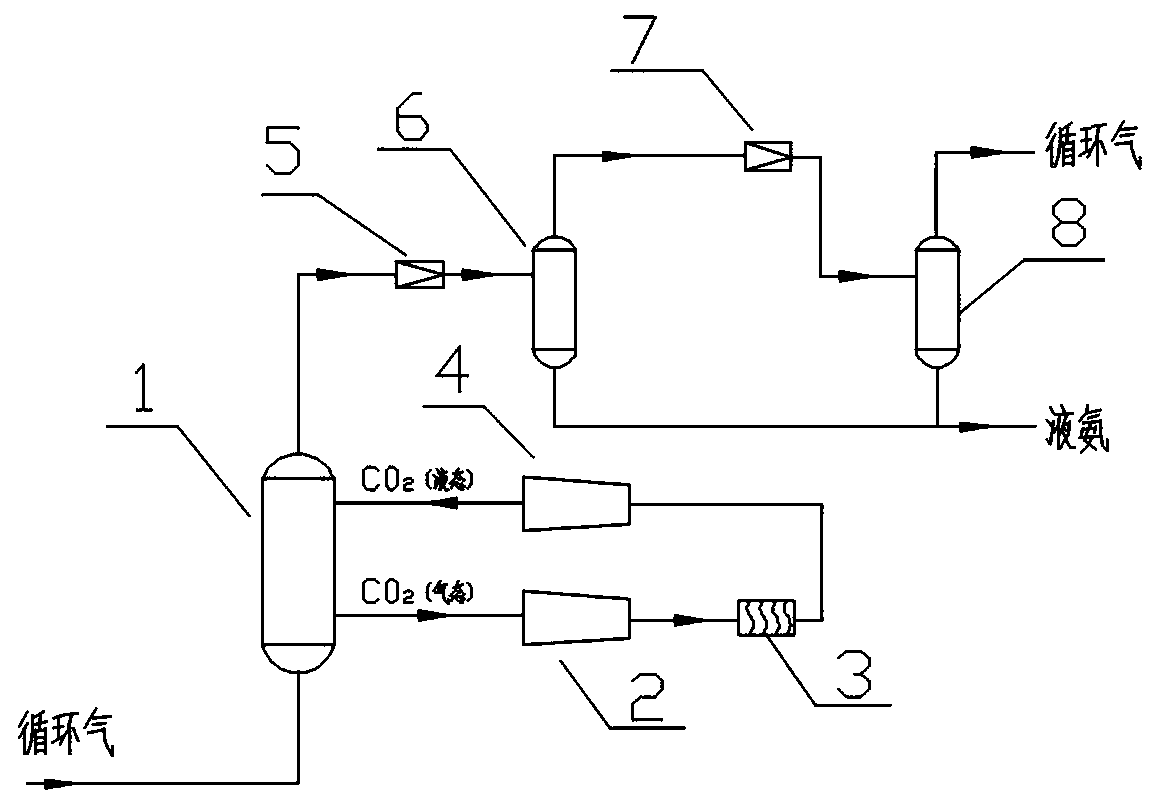

[0028] This embodiment is a method for condensing and separating liquid ammonia from the circulating gas of synthetic ammonia, and the specific steps include:

[0029] S1) CO 2 Compression boost of gas:

[0030] Select CO 2 Gas is used as the medium to provide cooling capacity, and the centrifugal compressor driven by the steam turbine is selected as the supercharger, and the CO 2 The gas first enters the compressor 2, the initial pressure P 1 =1.87 MPa, volume flow V 1 =12693.8 M3 / h, temperature T 1 =-20℃

[0031] In this embodiment, the steam pressure of the driving steam turbine is P=3.82 MPa, the steam consumption is 7t / h, and the shaft power is 1430KW.

[0032] CO 2 After the gas is compressed by compressor 2, P 2 =2.62 MPa, volume flow V 2 =16936 M3 / h, temperature T 2 =52°C, it can be known that CO 2 The gas obtains 5148MJ energy through compressor 2.

[0033] S2) Compressed CO 2 The heat exchange pressure between the gas and the cold water through the corru...

Embodiment 2

[0040] CO in this example 2 The volume of gas, the pressure of initial circulating gas are all identical with embodiment one, and concrete steps comprise:

[0041] S1) CO2 gas is passed into the compressor 2 to compress and cool down; the CO 2 The initial pressure of the gas P 1 =1.85MPa, temperature T 1 =-18°C, the CO after being compressed by compressor 2 2 Gas pressure P 2 =2.60MPa, temperature T 2 =50°C.

[0042] S2) The compressed CO 2 The gas passes into the corrugated plate heat exchanger 3, and the CO after heat exchange with cold water 2 Gas pressure P 3 =P 2 , temperature T 3 down to 39°C.

[0043] S3) CO after cooling 2 The gas makes gaseous CO in an isentropic expansion system 2 Condensed into a liquid state; the isentropic expansion system includes an impeller type isentropic expander 4, and the high-pressure CO 2The temperature of the gas in the isentropic expander 4 in the adiabatic state drops through the impeller to make the gaseous CO 2 Condens...

Embodiment 3

[0049] In this embodiment, the volume of CO2 gas and the pressure of the initial circulating gas are all the same as in Embodiment 1, and the specific steps include:

[0050] S1) CO 2 The gas is passed into the compressor 2 to compress and cool down; The CO 2 The initial pressure of the gas P 1 =1.88MPa, temperature T 1 =-19°C, the CO after being compressed by compressor 2 2 Gas pressure P 2 =2.64MPa, temperature T 2 =55°C.

[0051] S2) The compressed CO 2 The gas exchanges heat with cold water, making the CO 2 Gas cooling; the cold water heat exchange method is to CO 2 The gas passes into the corrugated plate heat exchanger 3, and the CO after heat exchange with cold water 2 Gas pressure P 3 =P 2 , temperature T 3 down to 42°C.

[0052] S3) CO after cooling 2 The gas makes gaseous CO in an isentropic expansion system 2 Condensed into a liquid state; the isentropic expansion system includes an impeller type isentropic expander 4, and the high-pressure CO 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com