Nanofiber carbon black conductive paper and preparation method thereof

A nanofiber, conductive paper technology, applied in the field of papermaking, can solve the problems of limiting the application field of conductive paper, low electrical conductivity and stability, low electrical conductivity of paper, etc., to broaden the scope of use, promote good dispersion, and improve pulp uniformity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

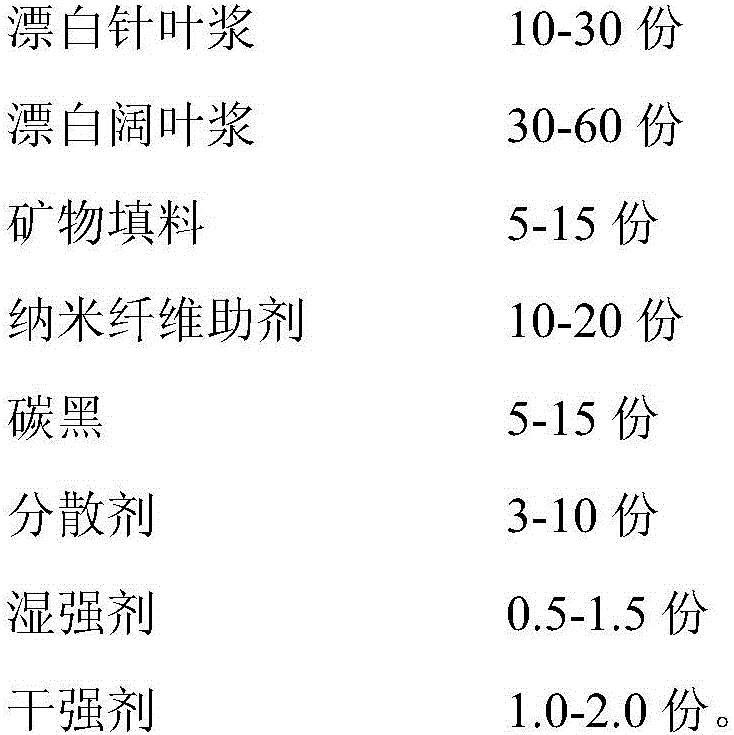

Method used

Image

Examples

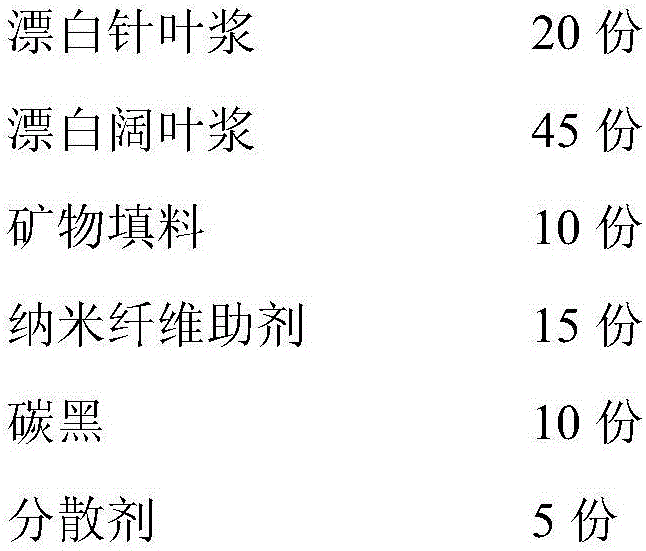

Embodiment 1

[0038] (1) Put the bleached coniferous pulp and bleached hardwood pulp into the pulper respectively, first crush the bleached softwood pulp, and then crush the bleached hardwood pulp, fully disintegrate at 38°C, and control the degree of knocking to 35°SR, 42°C respectively °SR, after the mass concentration reaches 4.5%, add nanofiber additives and stir well, then pump it into the pulping tank for standby;

[0039] (2) Dilute the mineral filler with water to a mass concentration of 55%, add carbon black and stir fully, and rotate at 2500 rpm to make the mineral filler and carbon black disperse evenly, and finally pump into the crushing tank of step (1) and step ( 1) The obtained product is mixed uniformly to obtain a mixed slurry;

[0040] (3) After the pulp mixed in step (2) is defiberized, the fiber is cut off and divided into filaments by refining; Fill in wet strength agent, dry strength agent and dispersant, adjust the mass concentration to 2.5%, pH value 6.9, and finall...

Embodiment 2

[0044] (1) Put the bleached coniferous pulp and bleached hardwood pulp into the pulper respectively, first crush the bleached softwood pulp, then the bleached hardwood pulp, fully disintegrate at 45°C, and control the degree of knocking to 32°SR, 37° °SR, after the mass concentration reaches 4.0%, add nanofiber additives and stir well, then pump it into the pulping tank for standby;

[0045](2) Dilute the mineral filler with water to a mass concentration of 55%, add carbon black and stir fully, and rotate at 2500 rpm to make the mineral filler and carbon black disperse evenly, and finally pump into the crushing tank of step (1) and step ( 1) The obtained product is mixed uniformly to obtain a mixed slurry;

[0046] (3) After the pulp mixed in step (2) is defiberized, the fiber is cut off and divided into filaments by refining; Fill in wet strength agent, dry strength agent and dispersant, adjust the mass concentration to 2.5%, pH value 7.1, put the slurry into the forebear po...

Embodiment 3

[0050] (1) Put the bleached coniferous pulp and bleached broadleaf pulp into the pulper respectively, first crush the bleached coniferous pulp, and then crush the bleached broadleaf pulp, fully disintegrate at 35°C, and control the degree of knocking to 32°SR, 37° °SR, after the mass concentration reaches 4.0%, add nanofiber additives and stir well, then pump it into the pulping tank for standby;

[0051] (2) Dilute the mineral filler with water to a mass concentration of 55%, add carbon black and stir fully, and rotate at 2500 rpm to make the mineral filler and carbon black disperse evenly, and finally pump into the crushing tank of step (1) and step ( 1) The obtained product is mixed uniformly to obtain a mixed slurry;

[0052] (3) After the pulp mixed in step (2) is defiberized, the fiber is cut off and divided into filaments by refining; Fill in wet strength agent, dry strength agent and dispersant, adjust the mass concentration to 2.5%, pH value 7.1, put the slurry into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com