Micro-tube yield increase device and method for marine shallow natural gas hydrates

A hydrate and natural gas technology, which is applied in earth-moving drilling, wellbore/well components, construction, etc., can solve the problems of difficult construction of horizontal wells, fast deposition rate, weak degree of reservoir cementation, etc. The effect of heat and mass transfer efficiency and flow conductivity, expanding contact area, and improving production increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

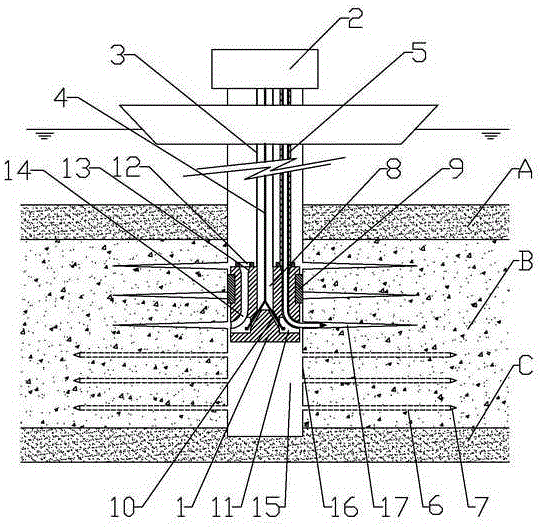

[0025] Such as figure 1 and figure 2 As shown, a marine shallow natural gas hydrate microtube stimulation device of the present invention is composed of a guide device 1, a wellhead device 2, a central pipe string 3, a cable 4, a thick-walled conduit 5, a microtube 6, and a pilot bit 7. .

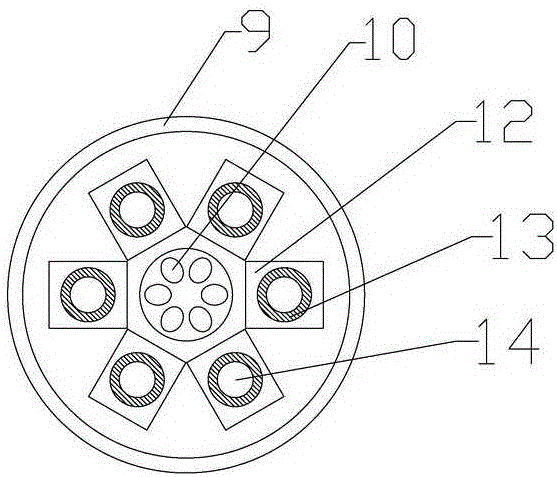

[0026]The guide device 1 includes a central channel 8, a seat seal mechanism 9, an inclined hole 10, an electrochemical cutter 11, a positioning mechanism 12, a guide cone 13 and a guide hole 14; the guide hole 14 is a circular channel with a suitable curvature, and the guide hole 14 are arranged in six, and the six guide holes 14 are symmetrically distributed around the central passage 8; there are six electrochemical cutters 11, and the six electrochemical cutters 11 are respectively connected with the outlets of the six guide holes 14 for Micropipe 6 carries out cutting operation. The central pipe string 3 is used to connect the central channel 8 of the guiding device 1 , to lower th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com