Wind turbine wind pressure variable-pitch whole-process control device

A control device and pitch variable technology, which is applied in the control of wind turbines, engine control, wind turbines, etc., can solve the problems that the wind turbine cannot be fully controlled, elastic materials are prone to fatigue failure, and the pitch angle adjustment range is small. Achieve excellent anti-gale performance, compact structure, and adapt to a wide range of wind speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

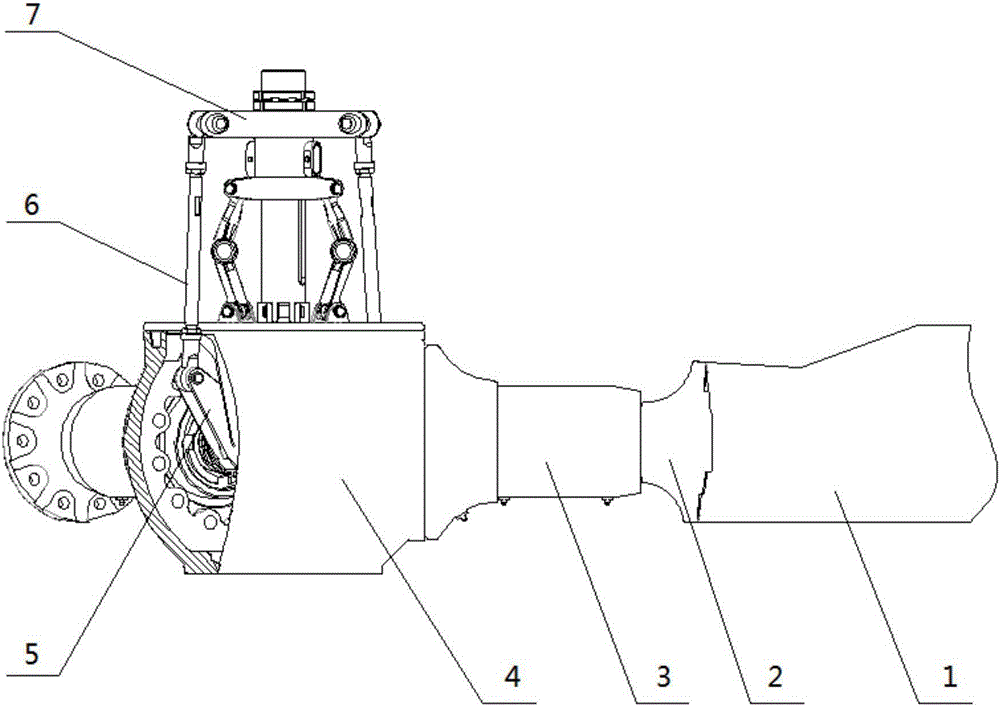

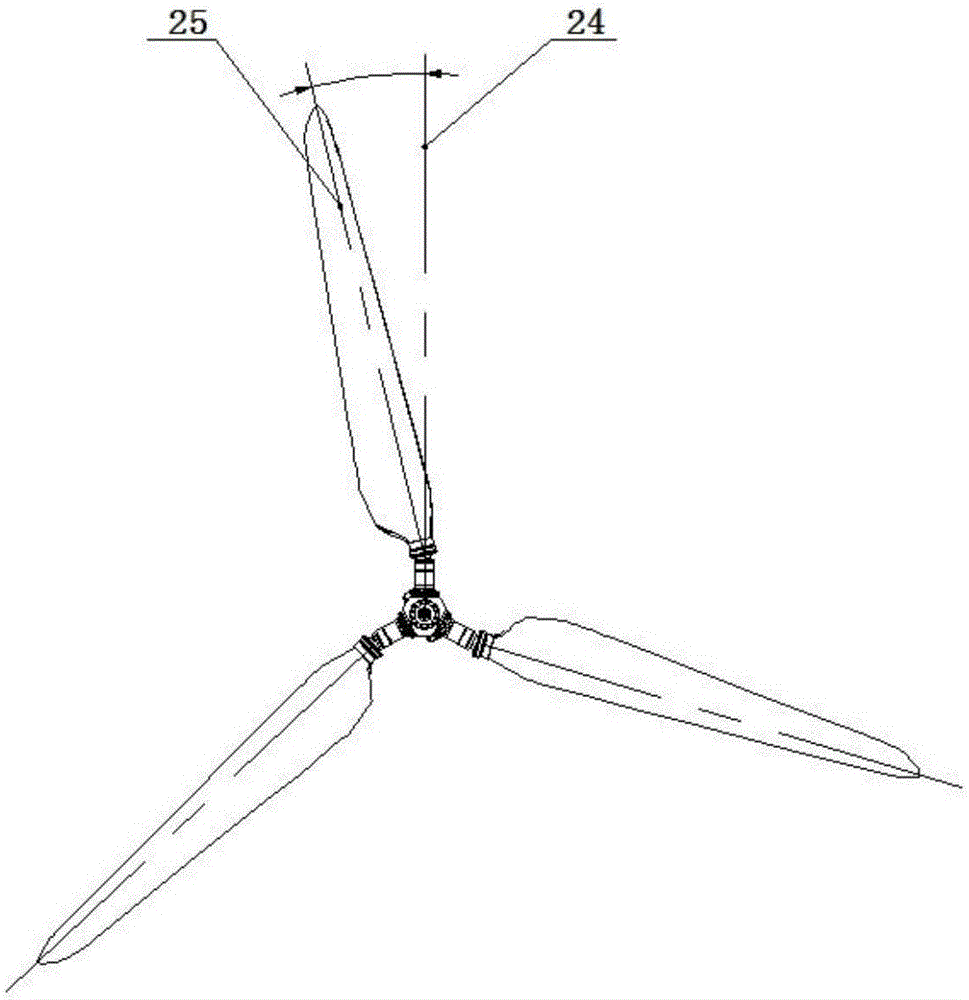

[0037] Such as figure 1 As shown, the wind pressure variable pitch control device of the present invention includes a hub 4, a blade 1 and a pitch actuator, and the hub includes a left end face, a right end face and three evenly distributed hollow disc-shaped circular end faces. A spoke sleeve 3 is fixed on each circular end surface, and a paddle shaft 2 is installed in the spoke sleeve. The paddle shaft and the spoke sleeve are coaxial, and the paddle shaft can rotate flexibly in the spoke sleeve. The rocker arm 5 that can rotate the blade shaft is installed, and the flange plate connecting the blade is installed on the outer end. The blade is fixed on the flange plate. There is a certain angle between 25 and the blade shaft axis 24, such as figure 2 As shown, the included angle is 3 degrees in this embodiment.

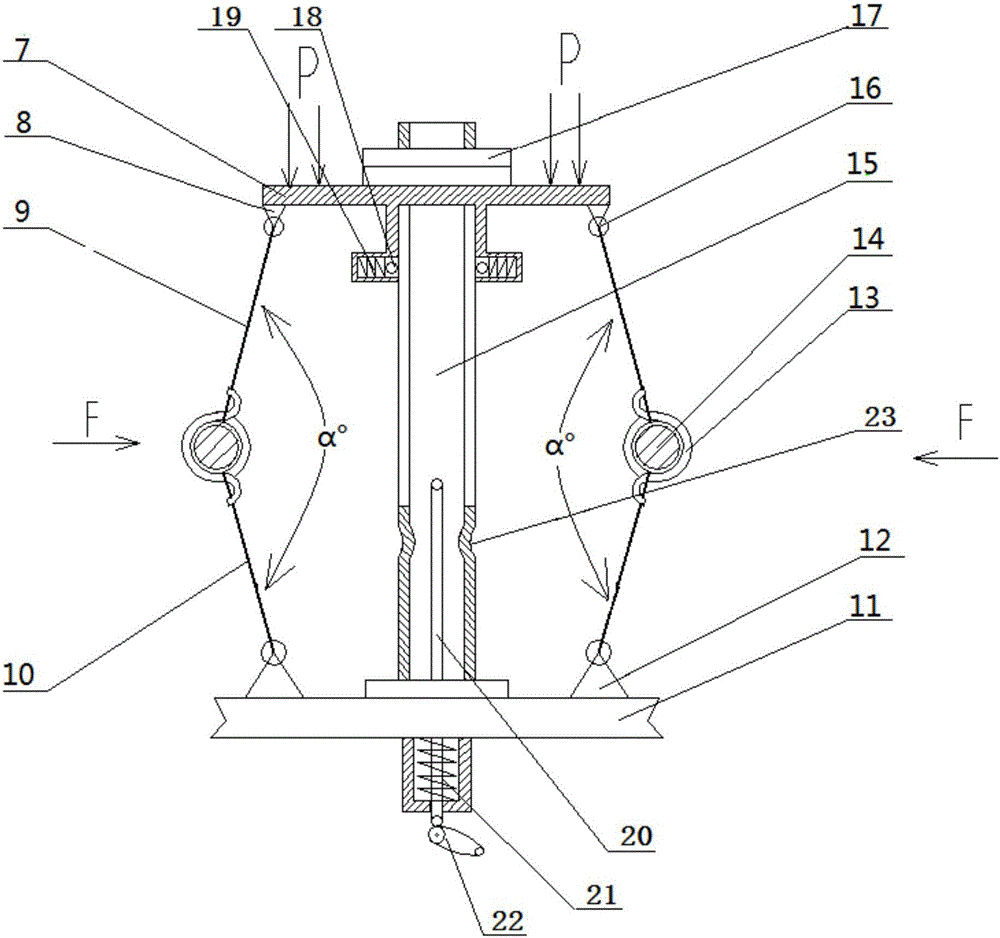

[0038] Such as figure 1 , 3As shown, the pitch actuator includes a pitch mechanism seat 11, a pull rod 6, a synchronous disk 7 and a shear elastic balance unit,...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the hub includes a left end face, a right end face, and four evenly distributed hollow disk-shaped circular end faces, that is to say, there are four blades, and the distance between the chord line of the blade and the axis of the blade shaft after assembly is The included angle between them is 5 degrees, and the compression rod I, the compression rod II and the tension spring (or torsion spring) in the shear elastic balance unit are configured in 5 groups.

[0055] All the other are identical with embodiment 1.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that the hub includes a left end face, a right end face, and six evenly distributed hollow disc-shaped circular end faces, that is to say, there are six blades, and the distance between the chord line of the blade and the axis of the blade shaft after assembly is The included angle between them is 8 degrees, and there are 8 sets of compression rod I, compression rod II and tension spring (or torsion spring) configuration components in the shear elastic balance unit.

[0058] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com