Coke-oven gas waste heat high-low-temperature comprehensive recycling system and method

The technology of a recovery system and recovery method is applied in the field of high and low temperature comprehensive recovery system for waste heat of waste gas, which can solve the problems of affecting heat exchange efficiency, narrow recovery temperature range, and complex composition of waste gas, so as to improve the life of heat exchangers and reduce the cost of enterprises. The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

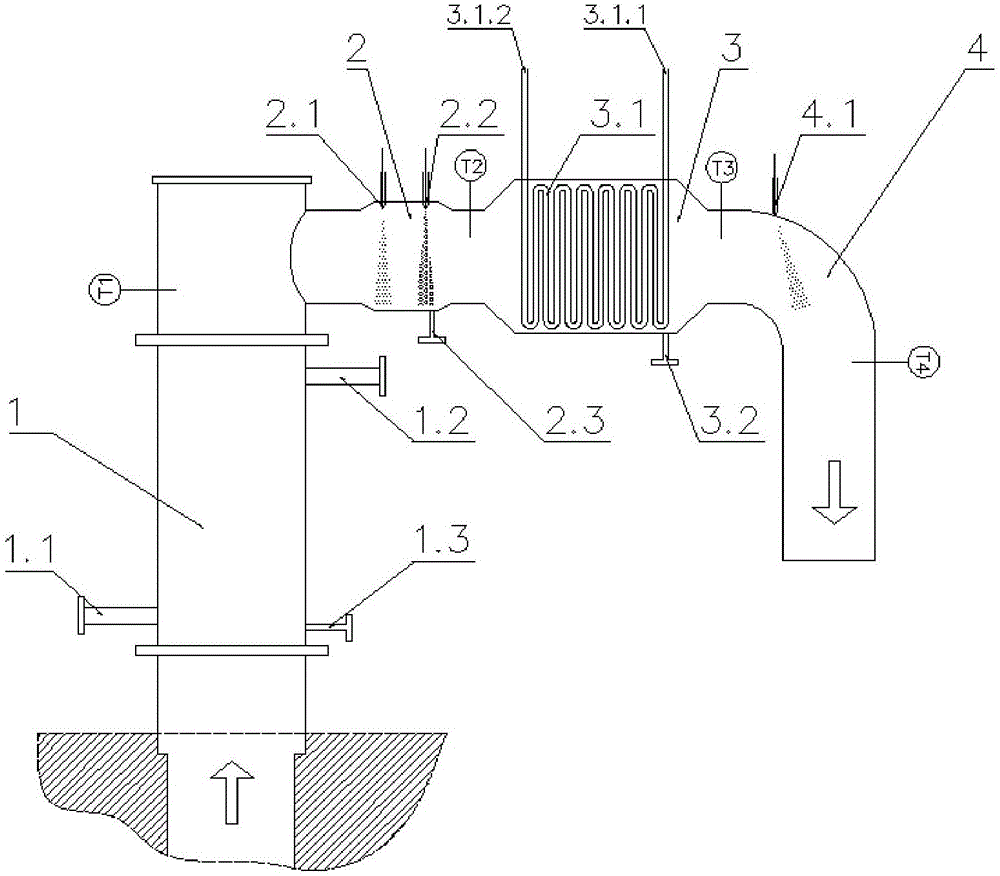

[0034] Such as Figure 1-2 As shown, this embodiment provides a high-low temperature comprehensive recovery method for waste heat of raw coal gas. The system includes a high-temperature heat exchanger 1 , a medium-temperature spray cooler 2 , a low-temperature heat exchanger 3 and a low-temperature spray cooler 4 .

[0035] The high-temperature raw gas above 650°C coming out of the coking chamber enters the high-temperature heat exchanger 1 for heat exchange, and the temperature of the raw gas at the outlet of the high-temperature heat exchanger drops to about 470°C, recovering the first part of high-temperature waste heat. If the heat exchange medium is liquid, it adopts the form of downstream heat exchange. The heat exchange medium enters the heat exchanger from the inlet 1.1 of the working medium side of the high temperature heat exchanger 1, and leaves the heat exchanger from the outlet 1.2 of the working medium side; if the heat exchange medium adopts The gas medium adopt...

Embodiment 2

[0045] The difference between this embodiment and the above-mentioned embodiments is that the low-temperature heat exchanger and the high-temperature heat exchanger in this embodiment use the same working fluid. Therefore, in this embodiment, the two are connected in series. The heat exchanger is initially heated, and then enters the high-temperature heat exchanger to further improve the thermal quality of the heat exchange medium.

[0046] In the above embodiments, the intermediate temperature cooler adopts a rectangular box, and the box may not use a rectangular box, but a pipe with a circular cross section or other shapes.

[0047] In the above embodiment, the nozzle of the intermediate temperature cooler sprays ammonia water. It should be understood that the use of ammonia water here is a preferred embodiment mode, not the only one, and other cooling means in the field can also be used.

[0048] In the above embodiments, the nozzles in the cryocooler spray water mist. It s...

Embodiment 3

[0052] This embodiment provides a high and low temperature comprehensive recovery method for waste heat of raw gas comprehensively recovering waste heat of raw gas.

[0053] In order to achieve the above object, the high and low temperature comprehensive recovery method of waste gas waste heat of the present invention comprises the following steps:

[0054] S1 uses a high-temperature heat exchanger to exchange heat for raw gas, and controls the outlet gas temperature of the high-temperature heat exchanger to be 470±10°C;

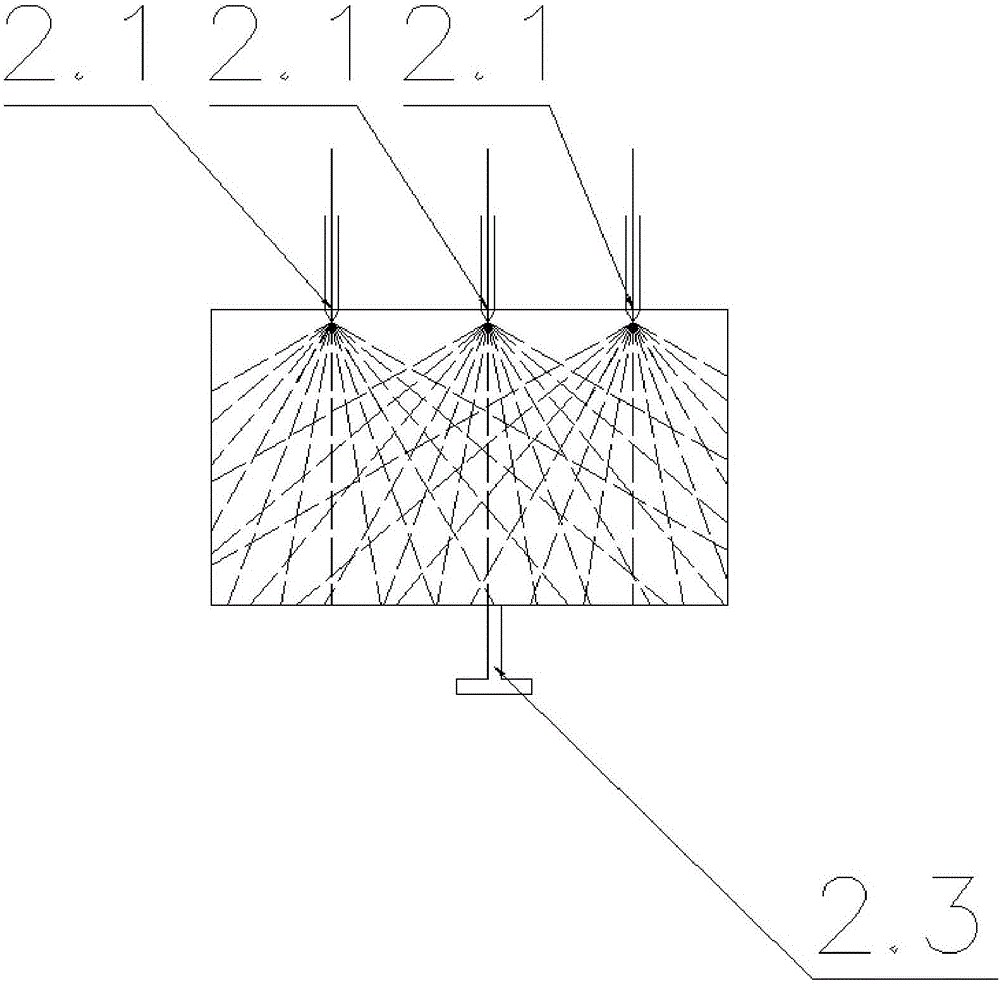

[0055] S2 uses a medium-temperature cooler to cool down the raw gas, and controls the outlet gas temperature of the medium-temperature cooler to 260±10°C; the medium-temperature spray cooler is arranged horizontally, and multiple fan-shaped nozzles are arranged at the inlet section. According to the ratio of length and width of the cooler, 1-3 nozzles are distributed on the top and side of the cooler. The high-pressure circulating ammonia water is sprayed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com