Amorphous silicon membrane photovoltaic module

A photovoltaic module and adhesive layer technology, applied in the field of solar cells, can solve the problem that solar cells cannot adapt to harsh environments, and achieve the effects of good mechanical safety performance, good general applicability, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

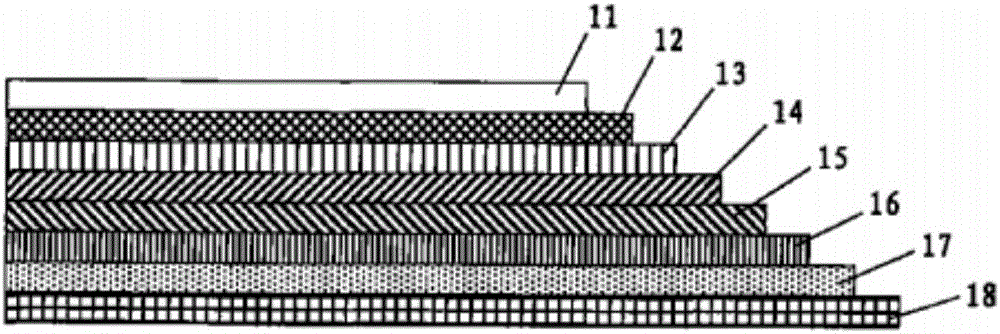

[0026] like Figure 2-3 As shown, an amorphous silicon thin film photovoltaic module includes: tempered glass 11 located outside the front glass 13 and bonded to the front glass 13 through an adhesive layer 12 . It is used to protect the front plate glass 13, which enhances the strength of the front panel of the solar cell. Preferably, the thickness of the tempered glass 11 is 5-15 mm, and the mechanical strength of the entire solar cell module is improved through the tempered glass.

[0027] The adhesive layer 12 is located between the toughened glass 11 and the front glass 13 and is used for bonding the front glass 11 and the toughened glass 12 together. It adopts transparent bonding material and has good light transmittance. Preferably, the adhesive layer 12 is made of polyvinyl butyral PVB, EVA resin or other transparent adhesive materials. Wherein, the EVA resin is an ethylene-vinyl acetate copolymer, and the general vinyl acetate (VA) content is 5% to 40%. Both polyv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com