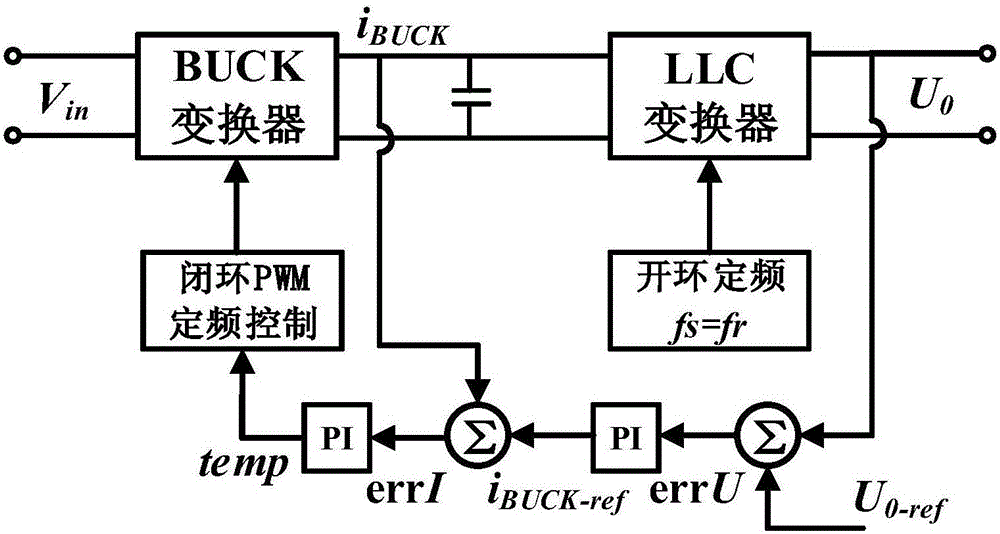

Double-loop constant-frequency control method based on BUCK-LLC (buck-logical link control) two-level DC/DC (direct current/direct current) converter

A control method and converter technology, applied in control/regulation systems, conversion of DC power input to DC power output, instruments, etc., can solve problems such as unfavorable engineering applications, weak anti-interference ability, complex control system design, etc., to achieve Strong anti-load disturbance ability, wide voltage input range and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

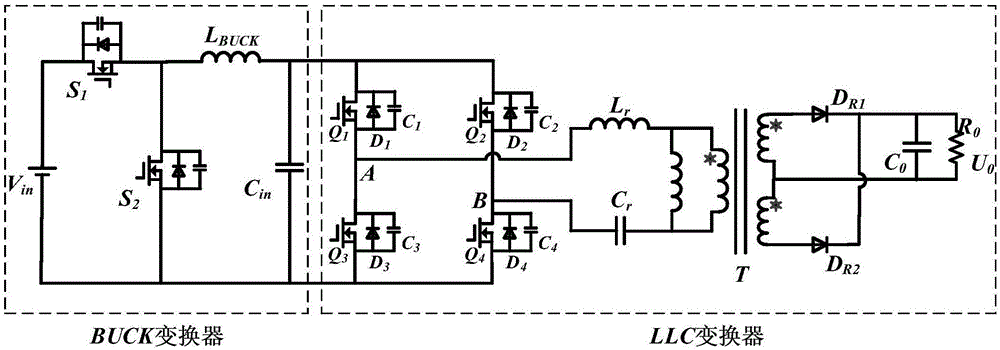

[0051] figure 1 It is a circuit topology diagram of the present invention, and it can be seen from this figure that the circuit topology involved in the present invention is a two-stage structure, and the front-stage BUCK converter includes a DC input voltage V in , switch tube S1, switch tube S2, inductor L BUCK , output capacitance C in ; The post-stage LLC converter includes switch tube Q1, switch tube Q2, switch tube Q3, switch tube Q4, and resonant inductor L r , Resonant capacitance C r , high frequency transformer T, diode D R1 , Diode D R2 , output capacitance C 0 , output load resistance R 0 .

[0052] The collector of the switch tube S1 is connected to the input voltage V in The positive pole of the switching tube S2 is connected to the emitter of the switching tube S1, and the emitter of the switching tube S2 is connected to the DC input v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com