Novel rotating rectifier with fault monitoring function

A rotating rectifier and fault monitoring technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, instruments, etc., can solve the problem of increasing armature current and field current of AC exciter, and easily burning out the insulation of excitation winding layer, high voltage of power supply, etc., to achieve the effects of reducing harmonics, fast transmission speed, and fewer switching devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

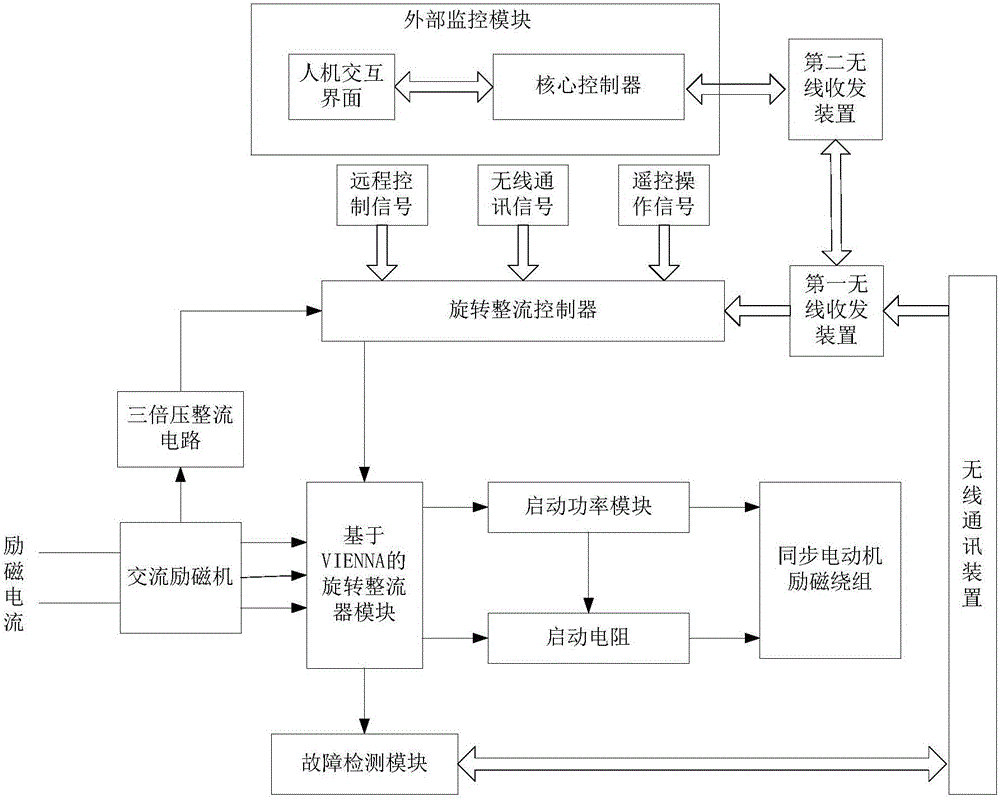

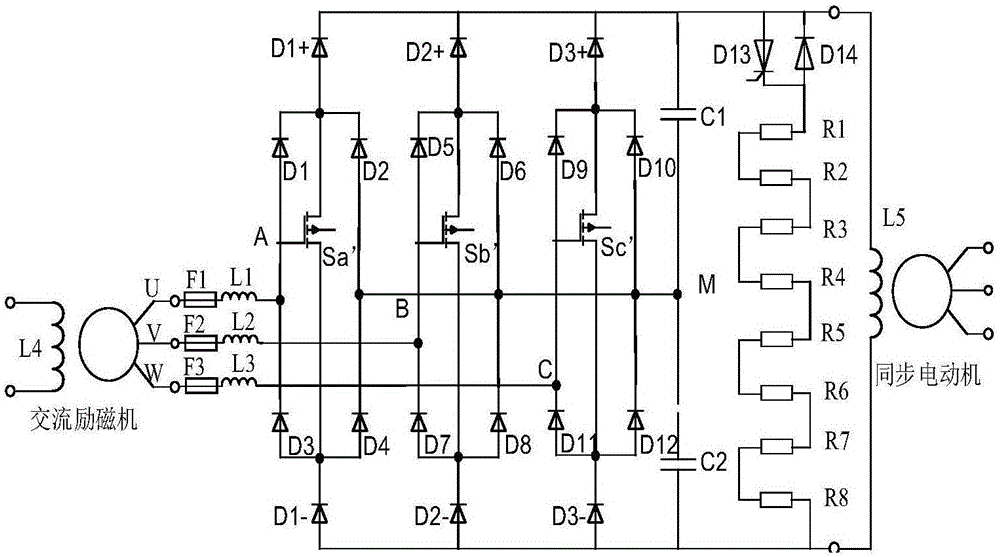

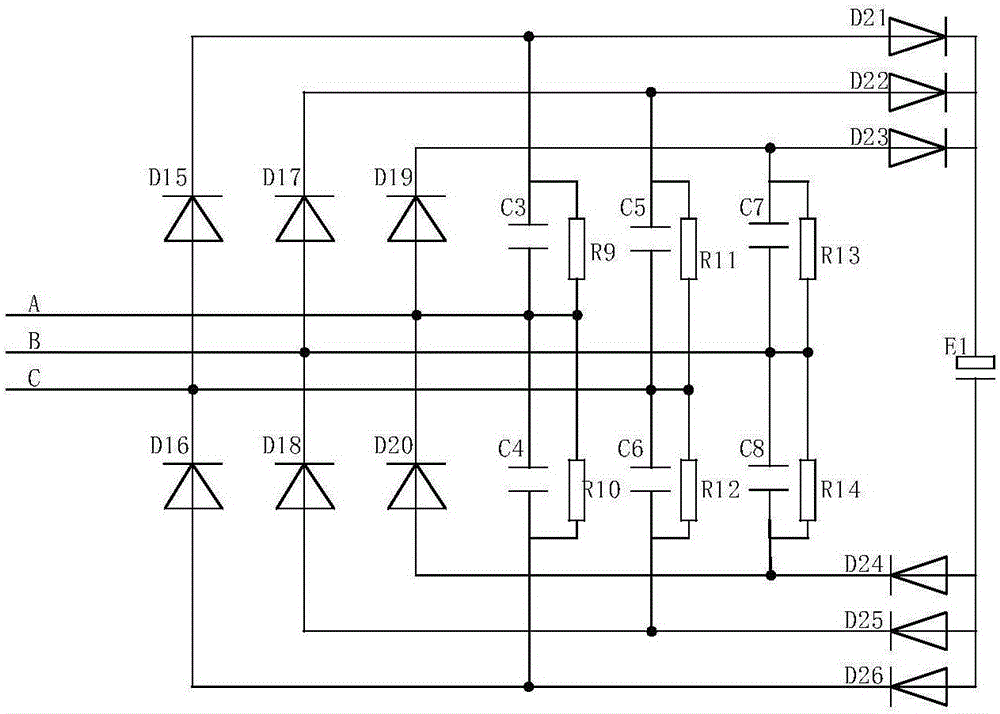

[0046] Specific implementation mode one: combine Figure 1~3Describe this embodiment, the novel rotary rectifier with fault monitoring function of this embodiment is as follows figure 1 As shown, including: AC exciter, three-phase triple voltage rectifier circuit, rotary rectifier controller, VIENNA-based rotary rectifier bridge module, starting power module, starting resistor, synchronous motor excitation unit, fault detection module, wireless communication device, A first wireless transceiver device, a second wireless transceiver device and an external monitoring module;

[0047] The input end of the AC exciter is connected to the input excitation current, the output end is connected to the VIENNA-based rotary rectifier bridge module and the input end of the three-phase triple voltage rectifier circuit, and the output end of the three-phase triple voltage rectifier circuit is connected to the rotary rectifier controller, the output end of the rotary rectification controller...

specific Embodiment approach 2

[0074] Specific implementation mode two: combination Figure 8-9 Describe this embodiment, the novel rotary rectifier with fault monitoring function of this embodiment, adopt the flow chart as Figure 9 The following method shown balances the midpoint voltage:

[0075] Step a, DC side two capacitor voltage V dc,上 and V dc,下 The reference voltage is V x,ref,DPWM,Vienna (x=a,b,c), V dc,上 and V dc,下 Will fluctuate up and down, judge V before fluctuating dc,上 increasing or decreasing trend to determine the injected zero-sequence voltage V Z direction: at V dc,上 Inject the moment to be reduced into a positive V Z (+) make V dc,上 increase, V dc,下 decrease; conversely, at V dc,上 Inject the moment to be increased into V Z (-) make V dc,上 decrease, V dc,上 Increase;

[0076] Step b. Determine the current I in the middle of the three input currents mid positive or negative, if I mid is positive, inject positive zero-sequence voltage V Z (+), if I mid is a negative valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com