IGBT drive circuit

A drive circuit, INV1 technology, applied in the direction of electrical components, electronic switches, pulse technology, etc., can solve the problem of long tail of current, solve the problem of surge voltage, reduce switching loss, and improve the effect of overshoot voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

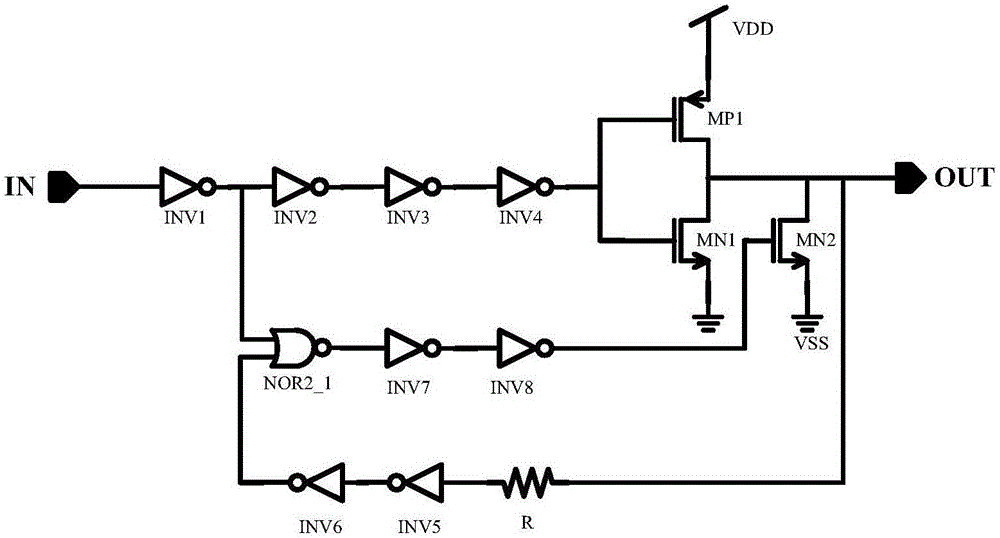

[0020] The present invention adopts the variable slope driving method, such as figure 1 Shown is an implementation form of the present invention, including a first inverter INV1, a second inverter INV2, a third inverter INV3, a fourth inverter INV4, a fifth inverter INV5, a sixth inverter Inverter INV6, seventh inverter INV7, eighth inverter INV8, PMOS transistor MP1, first NMOS transistor MN1, second NMOS transistor MN2, resistor R, two-input NAND gate NOR2_1, first inverter INV1 The input terminal of the input terminal is connected to the input signal IN, and the output terminal thereof is connected to the input terminal of the second inverter INV2 and the first input terminal of the two-input NOR gate NOR2_1; the input terminal of the third inverter INV3 is connected to the second inverter INV2 the output terminal of the fourth inverter INV4, the output terminal of which is connected to the input terminal of the fourth inverter INV4; the gates of the PMOS transistor MP1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com