Glass reinforced plastic material tower

A glass fiber reinforced plastic and material tower technology, which is applied to containers, packaging, underwater structures, etc., can solve the problems of easy agglomeration of feed, easy adhesion of feed, and large individuals, so as to achieve the effects of convenient and efficient cleaning and convenient and fast transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

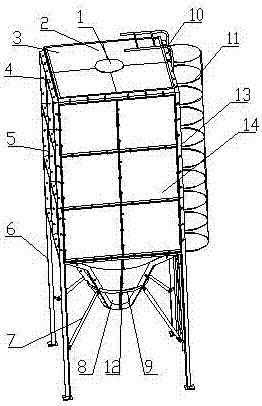

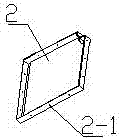

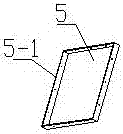

[0017] Embodiment: The fiberglass material tower as shown in the figure includes a tower body 13, a bracket 6 and a ladder 10, the bracket is installed outside the tower body, the ladder 10 is installed on one side of the tower body, and the ladder 10 is provided with Multiple protective rings 11 are convenient for later maintenance and cleaning, while ensuring the safety of staff. The tower body 13 is a square structure. The tower body 13 is composed of a tower cover 3, a housing 14 and a lower hopper 12 from top to bottom. The tower cover 3 is formed by connecting four cover pieces 2. The middle parts of the four cover pieces 2 It is the blanking hole 1, and the blanking hole 1 is provided with a cover plate. The casing 14 is spliced by several casing pieces 5; the lower hopper 12 is installed at the lower end of the casing 14, and the lower hopper 12 is spliced together by several arc-shaped variable-diameter pieces 8 to form an inverted cone, and the lower hopper 12 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com