Mineral additive

A mineral and weight ratio technology, applied in the field of mineral admixtures, can solve the problems of difficult construction and low early activity, achieve high early strength, improve early strength performance, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

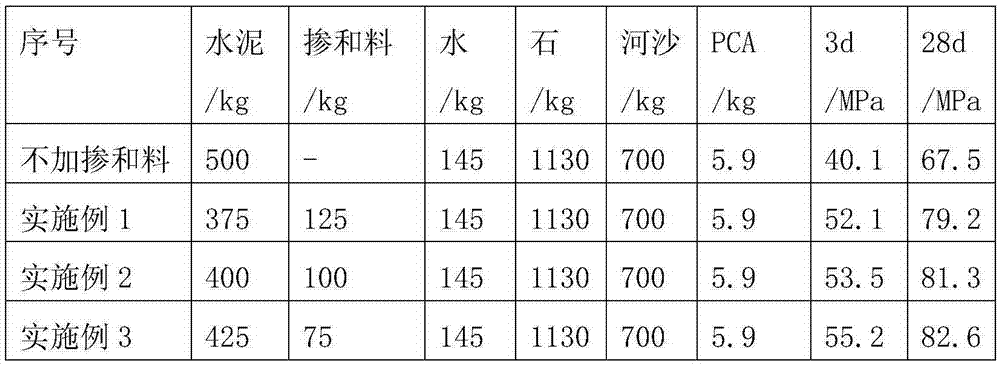

Examples

Embodiment 1

[0013] Embodiment 1 Preparation of mineral admixture of the present invention

[0014] Take 250kg of fly ash, 705kg of blast furnace slag, 5kg of dihydroxyethylethylenediamine, 10kg of sodium sulfate, and 30kg of calcium oxide, and mix them evenly to obtain the mineral admixture.

Embodiment 2

[0015] Embodiment 2 Preparation of mineral admixture of the present invention

[0016] Take 440kg of fly ash, 505kg of blast furnace slag, 15kg of dihydroxyethylethylenediamine, 30kg of sodium sulfate, and 10kg of calcium oxide, and mix them evenly to obtain the mineral admixture.

Embodiment 3

[0017] Embodiment 3 Preparation of mineral admixture of the present invention

[0018] Take 350kg of fly ash, 600kg of blast furnace slag, 10kg of dihydroxyethylethylenediamine, 20kg of sodium sulfate, and 20kg of calcium oxide, and mix them evenly to obtain a mineral admixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com