Preparation method of organic-inorganic modified carbon/montmorillonite composite adsorption material

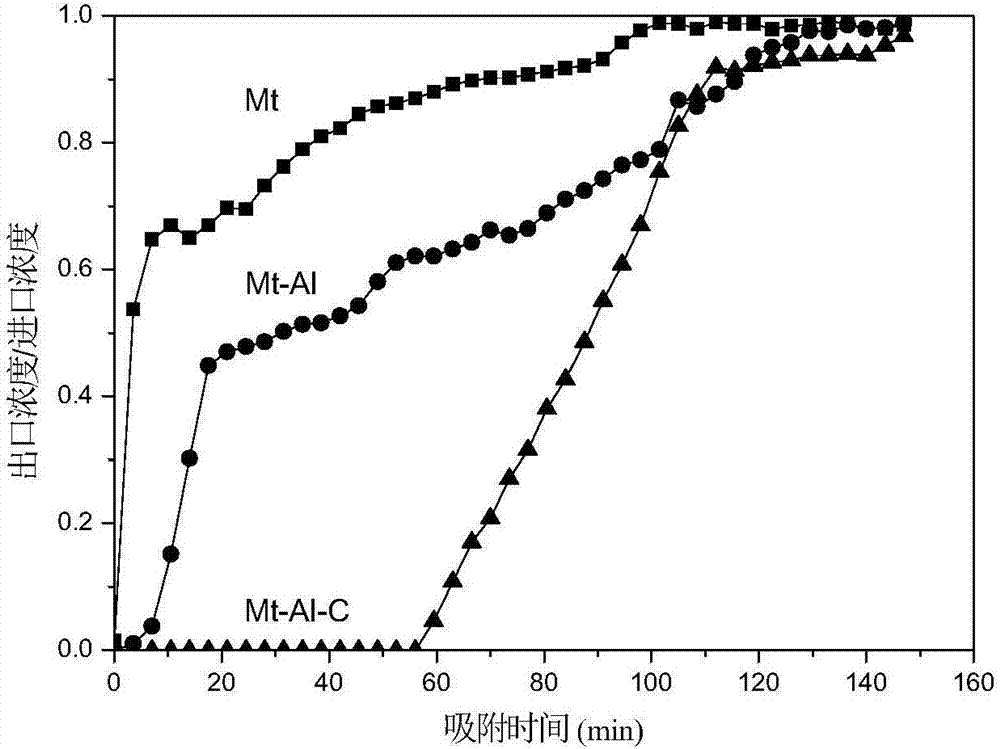

An inorganic modification and composite material technology, which is applied in the field of air purification and composite materials, can solve the problems of restricting the application of air purification and high price, achieve the effect of environmental protection preparation cost and improve adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of Inorganic Polymerized Hydroxyl Aluminum Cationic Pillars

[0031] At room temperature, weigh 0.05 mol of AlCl 3 Added to 0.6mol / L NaOH solution, so that OH in the mixed solution - with Al 3+ The molar ratio is 1:2.6; after uniform mixing, stir at room temperature for 24h.

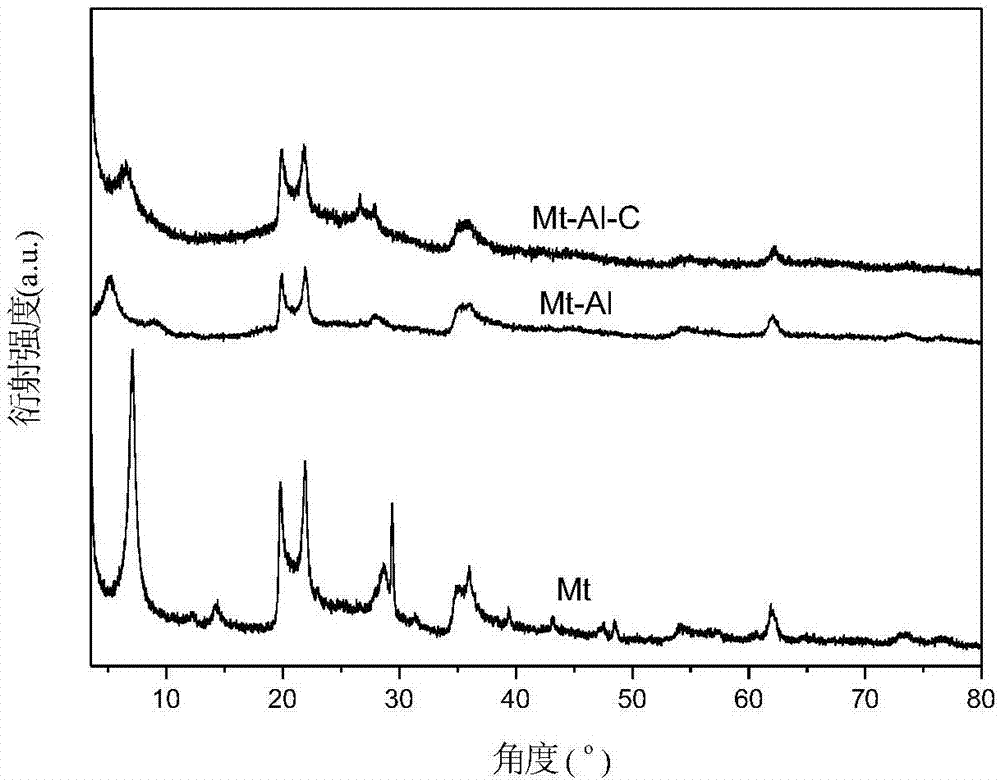

[0032] (2) Preparation of inorganic modified montmorillonite adsorption material

[0033] Weigh 10g of montmorillonite, add it to the above-mentioned proppant solution (wherein the amount of the inorganic polyhydroxyaluminum cation proppant is 5mmol / g montmorillonite), stir at room temperature for 24h, centrifuge, and obtain the solid substance repeatedly with distilled water Wash to free of Cl - It was then dried at 80°C and ground with an agate mortar.

[0034] (3) Preparation of organic-inorganic modified carbon / montmorillonite composites

[0035] Weigh 3 g of inorganically modified montmorillonite and 5 g of glucose and add them to deionized water, stir for 1 h, transfer ...

Embodiment 2

[0038] (1) Preparation of Inorganic Polymerized Hydroxyl Aluminum Cationic Pillars

[0039] At 60°C, weigh 0.04mol AlCl 3 Added to 0.8mol / L Na 2 CO 3 solution, so that OH in the mixed solution - with Al 3+ The molar ratio is 2.6:1; after uniform mixing, stir at room temperature for 24h.

[0040] (2) Preparation of inorganic modified montmorillonite adsorption material

[0041] Weigh 10g of montmorillonite, add it to the above-mentioned proppant solution (wherein the amount of the inorganic polyhydroxyaluminum cation proppant is 5mmol / g montmorillonite), stir at room temperature for 24h, centrifuge, and obtain the solid substance repeatedly with distilled water Wash to free of Cl - Then dry it at 80°C and grind it with an agate mortar.

[0042] (3) Preparation of organic-inorganic modified carbon / montmorillonite composites

[0043] Weigh 3 g of inorganically modified montmorillonite and 9 g of fructose and add them to deionized water, stir for 1 h, transfer the solution...

Embodiment 3

[0046] (1) Preparation of Inorganic Polymerized Hydroxyl Aluminum Cationic Pillars:

[0047] At 60°C, weigh 0.10mol AlCl 3 Added to 1.6mol / L Na 2 CO 3 solution, so that OH in the mixed solution - with Al 3+ The molar ratio is 2.6:1; after uniform mixing, stir at room temperature for 24h.

[0048] (2) Preparation of inorganic modified montmorillonite adsorption material

[0049] Weigh 10g of montmorillonite, add it to the above-mentioned proppant solution (wherein the amount of the inorganic polyhydroxyaluminum cationic proppant is 10mmol / g montmorillonite), stir at room temperature for 24h, centrifuge, and the obtained solid matter is repeatedly mixed with distilled water. Wash to free of Cl - Then dry it at 80°C and grind it with an agate mortar.

[0050] (3) Preparation of organic-inorganic modified carbon / montmorillonite composites

[0051] Weigh 3g of inorganically modified montmorillonite and 3g of maltose and add them to deionized water, stir for 1h, transfer the...

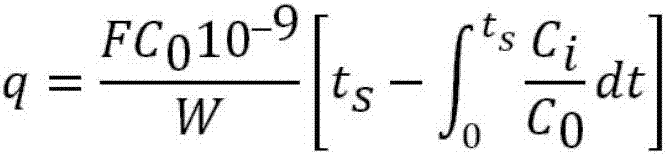

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com