Orderly and densely arranged microcavity structure membrane vacuum glass

A technology of vacuum glass and structural film, which is applied in the direction of glass/slag layered products, metal layered products, chemical instruments and methods, etc., which can solve problems such as interference, troubles in residents' lives, elevation, etc., to improve decoration and save lighting The effect of electricity consumption and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

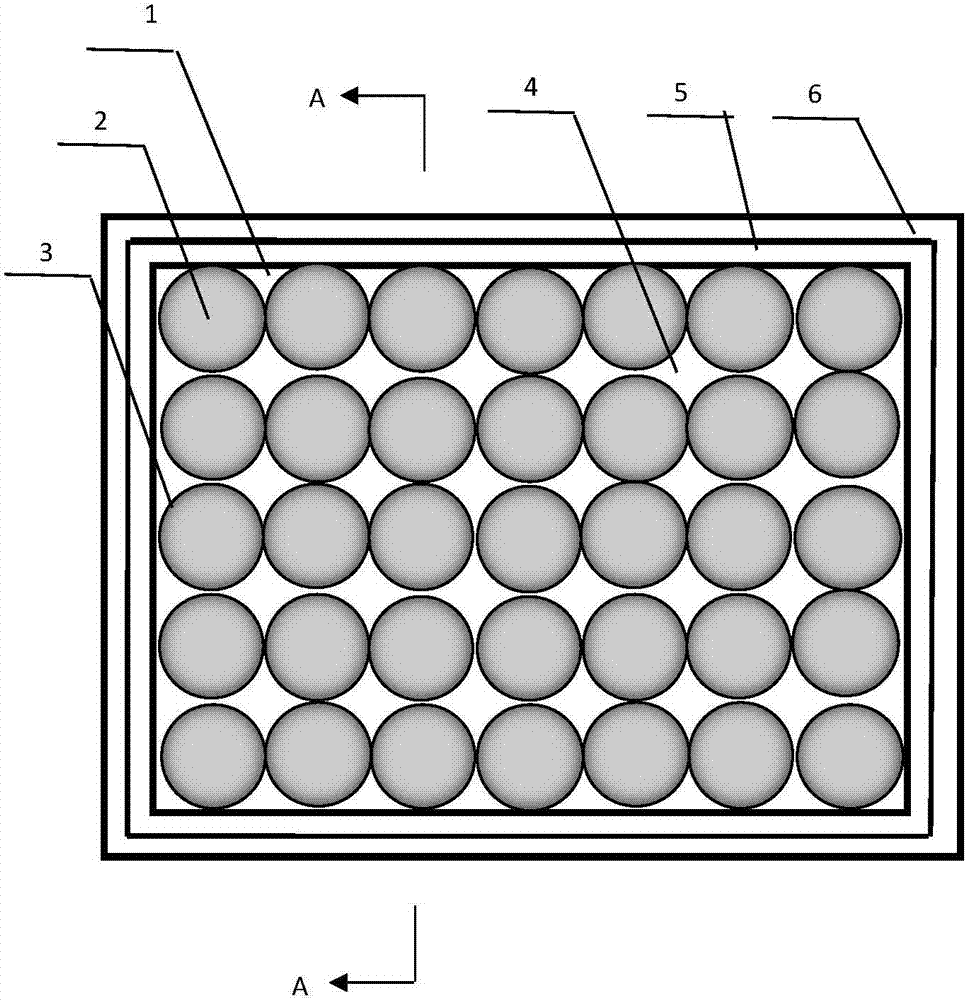

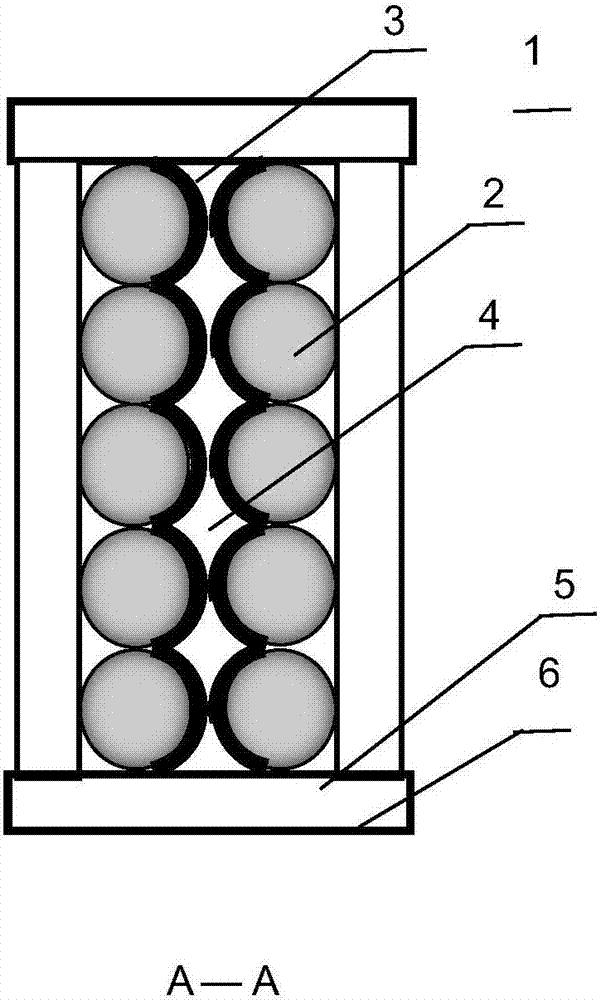

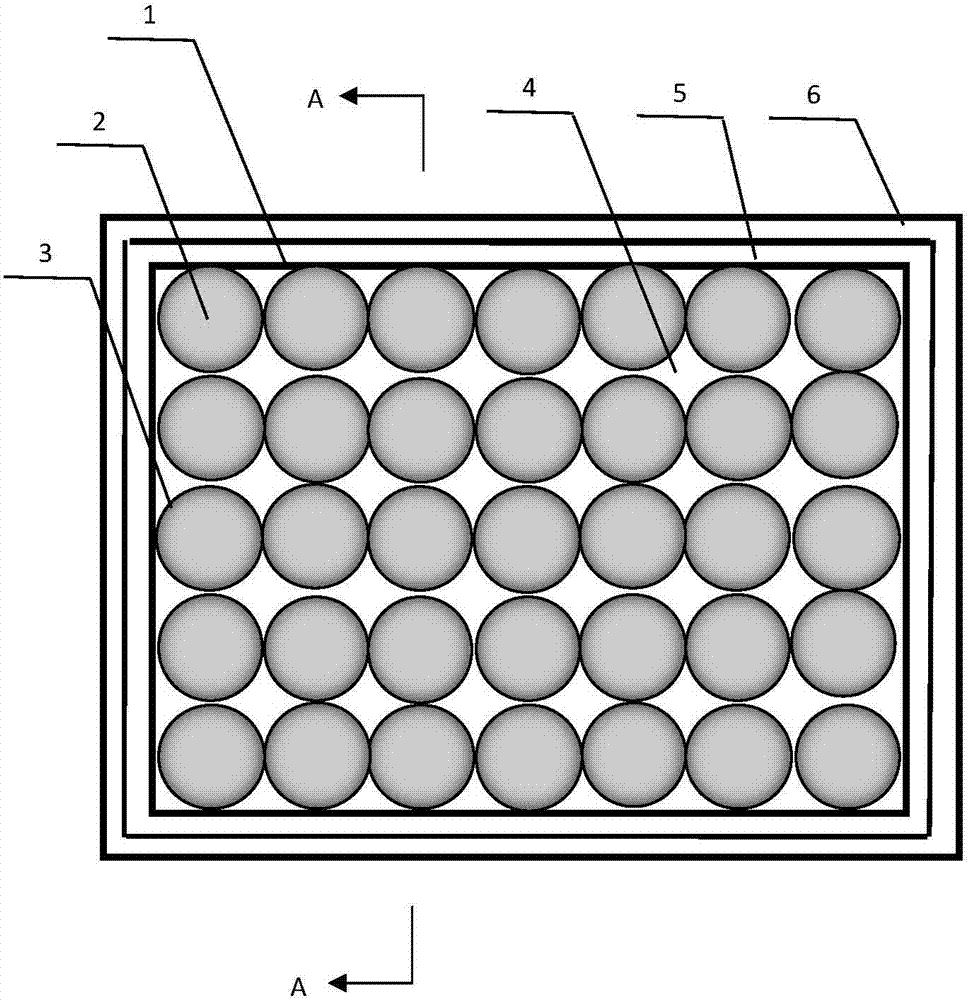

[0059] The ordered microcavity glass plate 1 of the present embodiment is a flat plate shape of 300 square centimeters, and there are two layers of closely arranged SiO inside it. 2 Microspheres 2. The scale of the microsphere 2 is 1 micron, and a metal Cu thin film 3 is arranged on its surface. The thickness of the thin film 3 is 30 nanometers, and the thin film 3 covers half of the spherical surface of the microsphere. There are small gap microcavities 4 between the closely arranged adjacent microspheres 2 in this layer. Nothing exists in the microcavity 4, and there is no air, and its vacuum gas pressure is less than 1×10 -1 Pa. A sealant 5 and a sealing frame 6 of alloy material are installed on the periphery of the glass plate 1 .

Embodiment 2

[0061] The ordered microcavity glass plate 1 of the present embodiment is a flat plate shape of 600 square centimeters, and a layer of closely arranged SiO is arranged inside it. 2 Microspheres 2. The scale of the microsphere 2 is 2 microns, and a metal Al film 3 is arranged on its surface. The thickness of the film 3 is 50 nanometers, and the film 3 covers half of the spherical surface of the microsphere. There is a small gap microcavity 4 between the closely arranged microspheres 2 of the first layer and the second layer. Nothing exists in the microcavity 4, and there is no air, and its vacuum gas pressure is less than 1×10 -1 Pa. A sealant 5 and a sealing frame 6 of alloy material are installed on the periphery of the glass plate 1 .

Embodiment 3

[0063] The ordered microcavity glass plate 1 of this embodiment is in the shape of a 600 square centimeter flat plate with a layer of closely arranged glass cones 2 inside. The scale of the cone 2 is 2 microns, and a layer of metal Al film 3 is arranged on its surface. The thickness of the film 3 is 50 nanometers, and the film 3 covers the side surface of the complete cone. There are small gaps of microcavities 4 between the closely arranged adjacent cones 2 in this layer. Nothing exists in the microcavity 4, and there is no air, and its vacuum gas pressure is less than 1×10 -1 Pa. A sealant 5 and a sealing frame 6 of alloy material are installed on the periphery of the glass plate 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com