High-moisture penetrability biodegradable composite material and production method thereof

A technology of biodegradable and composite materials, which is applied in the field of high moisture permeability biodegradable composite materials and its production, can solve the problems of insufficient moisture permeability and high production cost, and achieve high water vapor transmission rate, low production cost, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

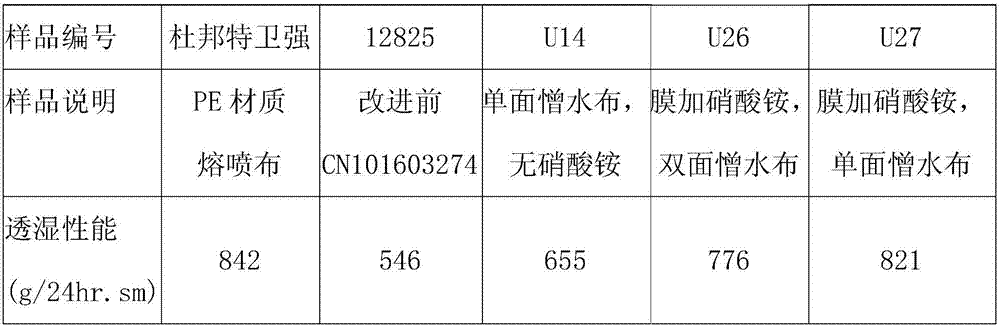

[0036]Containing 5% perfluorinated C6 acrylic acid copolymer emulsion (selected Japan Daikin TG-581), uniformly coated on one side of 45gsm polyvinyl alcohol spunlace nonwoven fabric by spraying method, coating amount is 1%, immediately Enter the oven to dry at a temperature of 120°C, and bake at a temperature of 175°C for 30 seconds. Roll up after cooling.

[0037] Take 100kg of 2499 polyvinyl alcohol and put it into a mixing vessel with 95°C jacket heating. Add 550kg of water, 11kg of glycerin, 0.125kg of polyethylene glycol laurate, and 10kg of ammonium nitrate, stir and dissolve for more than 2 hours for later use.

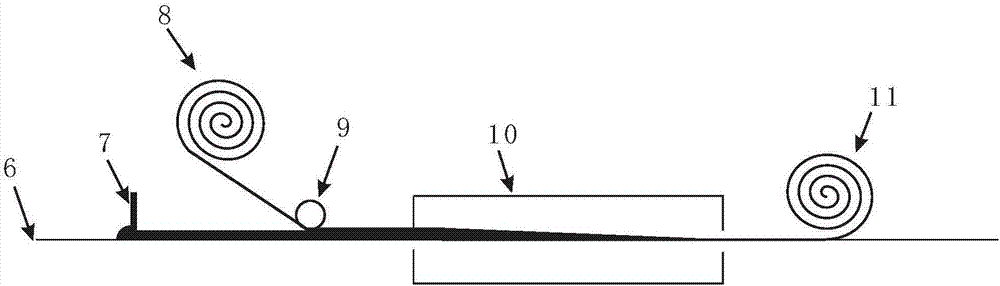

[0038] The above-mentioned dissolved polyvinyl alcohol solution is evenly coated on the frosted PET substrate, and the coating amount is 160gsm, and the above-mentioned polyvinyl alcohol spunlaced nonwoven fabric is flatly pasted on the wet film without tension, and the diameter is 15mm. After the sponge roller is gently rolled once, it is dried in an oven a...

Embodiment 2

[0041] In the above examples, the grammage of the polyvinyl alcohol spunlaced nonwoven fabric was changed to 62gsm. The obtained finished product was 91 gsm, and the moisture permeability was 755.23 g / d.sm.

Embodiment 3

[0043] Apply the perfluorinated C6 acrylic copolymer emulsion containing 10% (selected Asahi Glass AG-E82) evenly on one side of the 45gsm polyvinyl alcohol spunlace nonwoven fabric by spraying method, the coating amount is 1.5%, enter immediately The oven was dried at 120° C. and baked at 175° C. for 30 seconds. Roll up after cooling.

[0044] Take 100kg of 2499 polyvinyl alcohol and put it into a mixing vessel with 95°C jacket heating. Add 550kg of water, 9kg of glycerin, 0.3kg of polyethylene glycol laurate, and 20kg of ammonium nitrate, stir and dissolve for more than 2 hours for later use.

[0045] The above-mentioned dissolved polyvinyl alcohol solution is evenly coated on the frosted PET substrate, the coating amount is 150gsm, the above-mentioned polyvinyl alcohol spunlaced nonwoven fabric is flatly pasted on the wet film without tension, and the diameter is 15mm. After the sponge roller is gently rolled once, it is dried in an oven at a temperature of 120-140 ° C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com