A kind of preparation method of superhydrophobic sand

A super-hydrophobic and sand-based technology, which is applied to the surface coating device, coating, special surface, etc., can solve the problems of insufficient resources of super-hydrophobic materials, high production costs, poor heat resistance, etc., and achieve good water storage , high mechanical strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Sand pretreatment: wash a certain amount of sand with 100mL deionized water for 3 times, and then dry it for use.

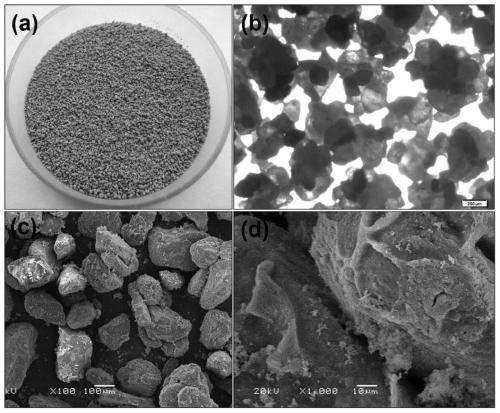

[0028] (2) Preparation of surface-coated silica sand: Add 5g of washed sand to 100mL of ethanol solvent, then add 50mL of cetyltrimethylammonium bromide with a concentration of 0.14M, and stir for 1 hour. The pH of the solution was adjusted to 13 with aqueous ammonia. Then, in the process of stirring, 10 mL of ethyl orthosilicate was added dropwise into the above solution, and the reaction was fully carried out for 12 hours. Then leave it to stand, remove the white dispersion liquid on the sand upper layer, fully wash the lower layer sand 3 times with deionized water, and obtain the sand that the surface is coated with silicon dioxide after drying (such as figure 1 shown).

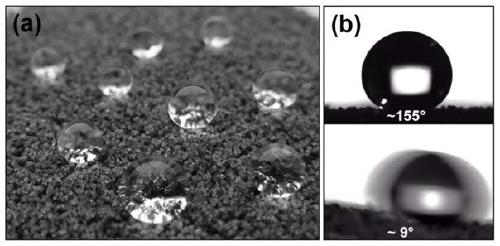

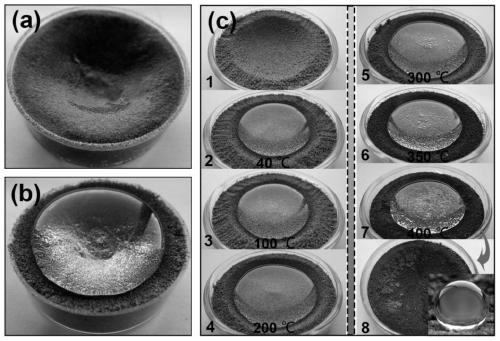

[0029] (3) Low surface energy modification: Add the sand coated with silica on the surface prepared in step B to 100 mL of a 0.5% perfluorodecyltriethoxysilane ethanol mixed solu...

Embodiment 2

[0033] (1) Sand pretreatment: wash a certain amount of sand with 100mL deionized water for 3 times, and then dry it for use.

[0034] (2) Preparation of surface-coated silica sand: add 10g of washed sand to 100mL of ethanol solvent, then add 50mL of cetyltrimethylammonium bromide with a concentration of 0.14M, stir well for 1h, The pH of the solution was adjusted to 13 with aqueous ammonia. Then, in the process of stirring, 15 mL of ethyl orthosilicate was added dropwise into the above solution, and the reaction was fully carried out for 12 hours. Then let it stand, remove the white dispersion liquid on the upper layer of the sand, fully wash the sand in the lower layer 3 times with deionized water, and obtain the sand coated with silicon dioxide on the surface after drying.

[0035] (3) Low surface energy modification: Add the sand coated with silica on the surface prepared in step B to 100 mL of a 0.5% perfluorodecyltriethoxysilane ethanol mixed solution, stir, and wait for...

Embodiment 3

[0037] (1) Sand pretreatment: wash a certain amount of sand with 100mL deionized water for 3 times, and then dry it for use.

[0038] (2 Preparation of surface-coated silica sand: add 10g of washed sand to 100mL of ethanol solvent, then add 50mL of cetyltrimethylammonium bromide with a concentration of 0.14M, stir thoroughly for 1 hour, and use Ammonia water adjusts the pH value of the solution to 12. Then, in the process of stirring, add 10mL tetraethyl orthosilicate dropwise to the above solution, and fully react for 10h. Then let stand, remove the white dispersion on the sand, and use The lower layer of sand is fully washed with ionized water for 3 times, and the sand coated with silicon dioxide is obtained after drying.

[0039] (3) Low surface energy modification: Add the sand coated with silica on the surface prepared in step B to 100 mL of a 0.5% perfluorodecyltriethoxysilane ethanol mixed solution, stir, and wait for 6 hours to react Later, the modified sand is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com