Method for preparing carbon fiber toughened zirconium boride-silicon carbide composite material by using slurry injection process

An injection process and composite material technology are applied in the field of preparing carbon fiber toughened ZrB2-SiC composite materials, which can solve the problems of easy damage of carbon fiber and difficulty in obtaining high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

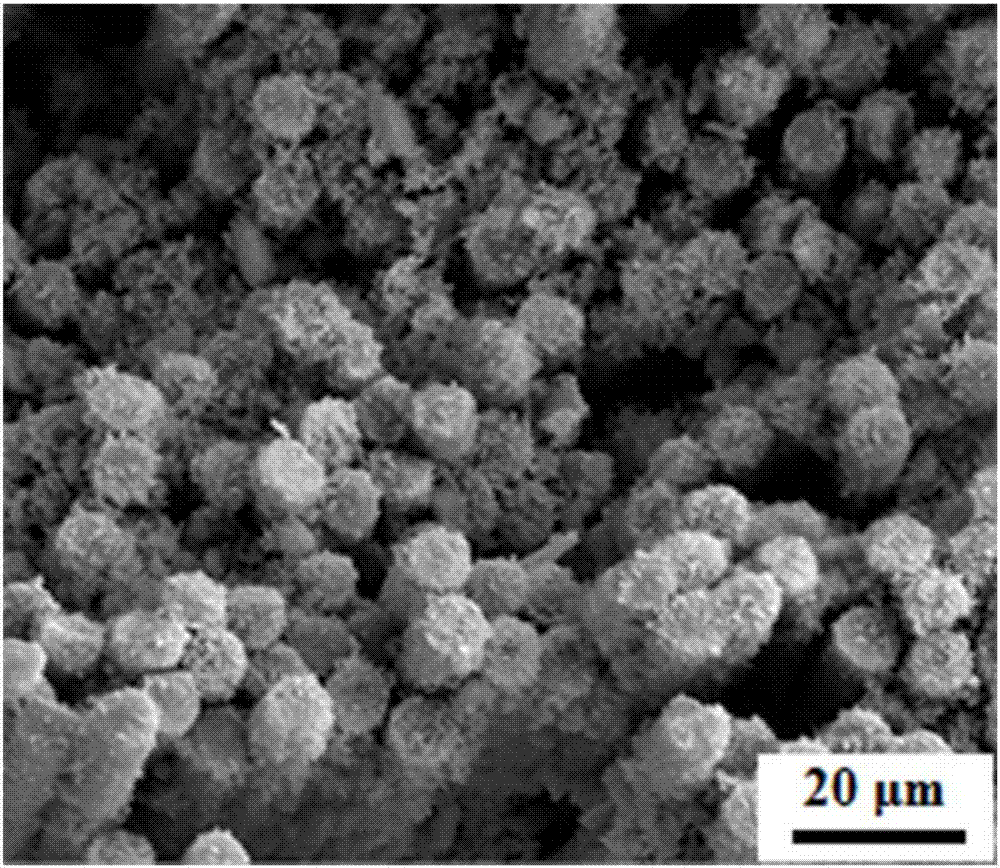

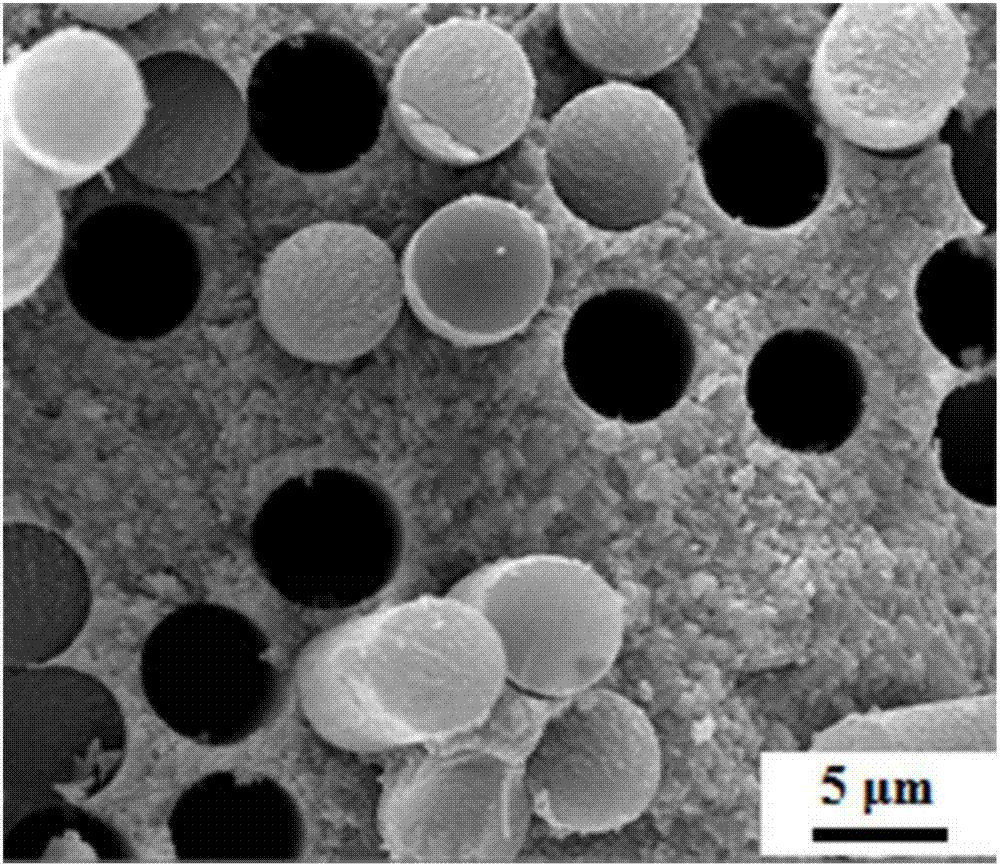

[0021] Embodiment 1: This embodiment is a method for preparing carbon fiber toughened zirconium boride-silicon carbide composite material by slurry injection process, which is completed according to the following steps:

[0022] 1. Preparation of ZrB 2 -SiC ceramic paste: ZrB 2 Powder and SiC powder are mixed to get ZrB 2 Powder and SiC powder mixed powder; ZrB 2 Add the mixed powder of powder and SiC powder into absolute ethanol, then add dispersant, and then ball mill for 3h~5h at the ball milling speed of 150r / min~300r / min to obtain uniformly dispersed ZrB 2 - SiC ceramic paste;

[0023] ZrB as described in step 1 2 ZrB in mixed powder of powder and SiC powder 2 The volume fraction of the powder is 60% to 70%;

[0024] ZrB as described in step 1 2 The volume fraction of SiC powder in the mixed powder of powder and SiC powder is 30% to 40%;

[0025] Dispersant and ZrB described in step one 2 The mass ratio of the mixed powder of powder and SiC powder (0.01~0.02):1; ...

specific Embodiment approach 2

[0036]Specific embodiment two: the difference between this embodiment and specific embodiment one is: ZrB described in step one 2 The particle size of the powder is 100nm-200nm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the SiC powder in step 1 has a particle size of 400nm-600nm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com