Walking hydraulic system of concrete pavement sympathetic vibration rock crushing plant

A cement pavement and hydraulic system technology, applied in the field of walking hydraulic system, can solve the problems of inability to achieve synchronous effect of driving wheels, different motor speeds, insufficient traction of mechanical equipment, etc., to facilitate heat exchange, prevent cavitation, and increase operating frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

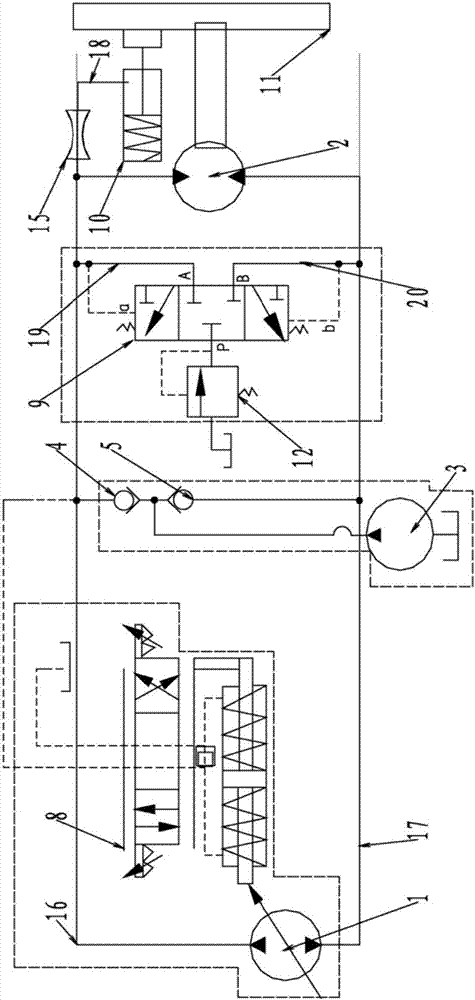

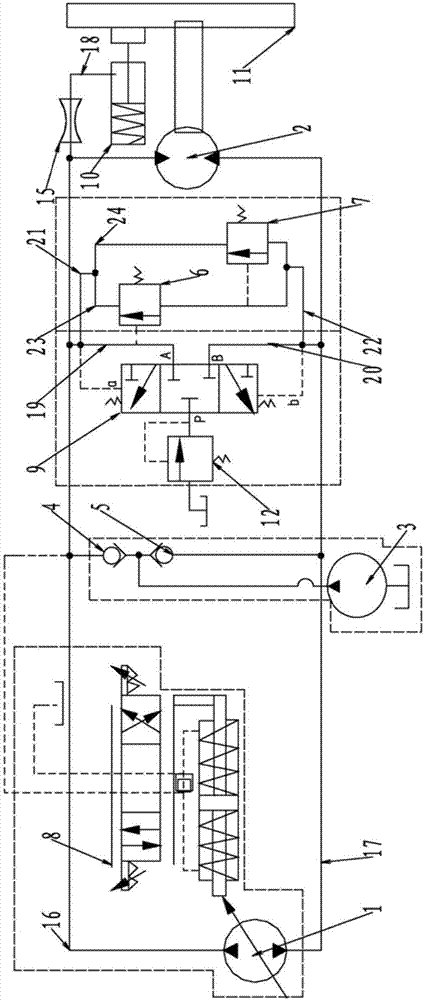

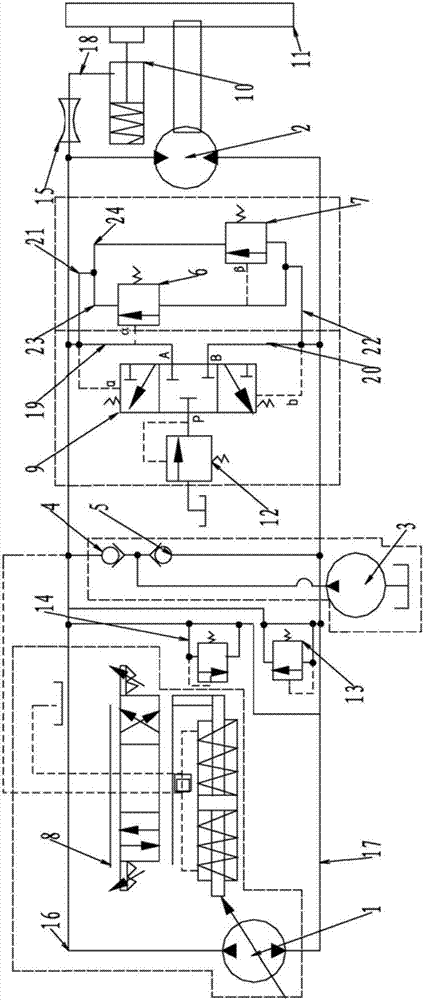

[0020] Such as Figure 1-3 As shown, the walking hydraulic system of the cement pavement resonant gravel equipment in this embodiment includes a volumetric speed control system, the oil output by the hydraulic pump directly enters the actuator, there is no overflow loss and throttling loss, and the working pressure changes with the load And changes, so the efficiency is high and the heat is less. The volume speed regulation system includes a variable pump and a quantitative motor 2 connected to the variable pump through pipelines; the quantitative motor 2 is used to drive the resonant gravel equipment on the cement road; a shuttle valve connected to the oil tank is connected in parallel between the two ports of the quantitative motor 2 9. The volume speed regulating system is a semi-closed system; the two-way variable pump 1 is connected with an electro-hydraulic proportional control valve 8, and the electro-hydraulic proportional control valve 8 controls the flow and reversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com