Optical pressure-sensitive paint dynamic pressure calibration cabin of standing wave tube type

A technology of dynamic pressure and standing wave tubes, which is applied in the calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc., which can solve problems such as easy distortion of waveforms, inaccurate measurement, and small frequency of pressure changes, and achieve Avoiding pressure wave energy loss, accurate experimental optical measurement, and reducing optical influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

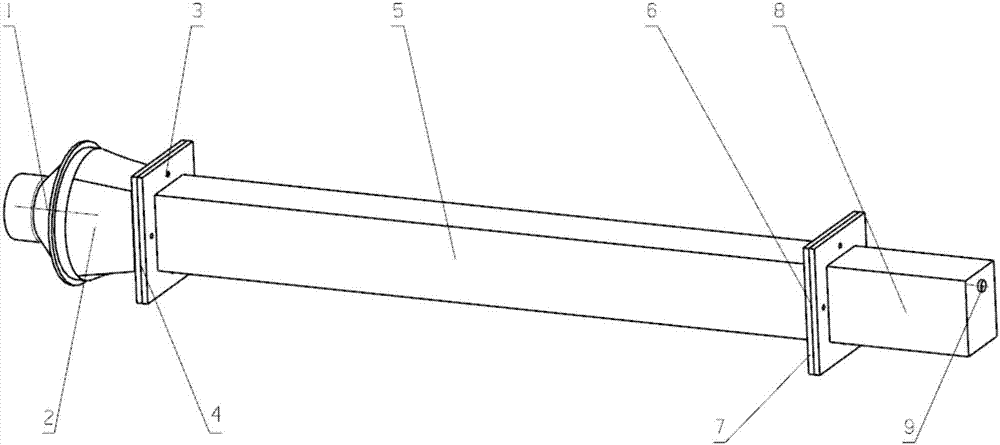

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

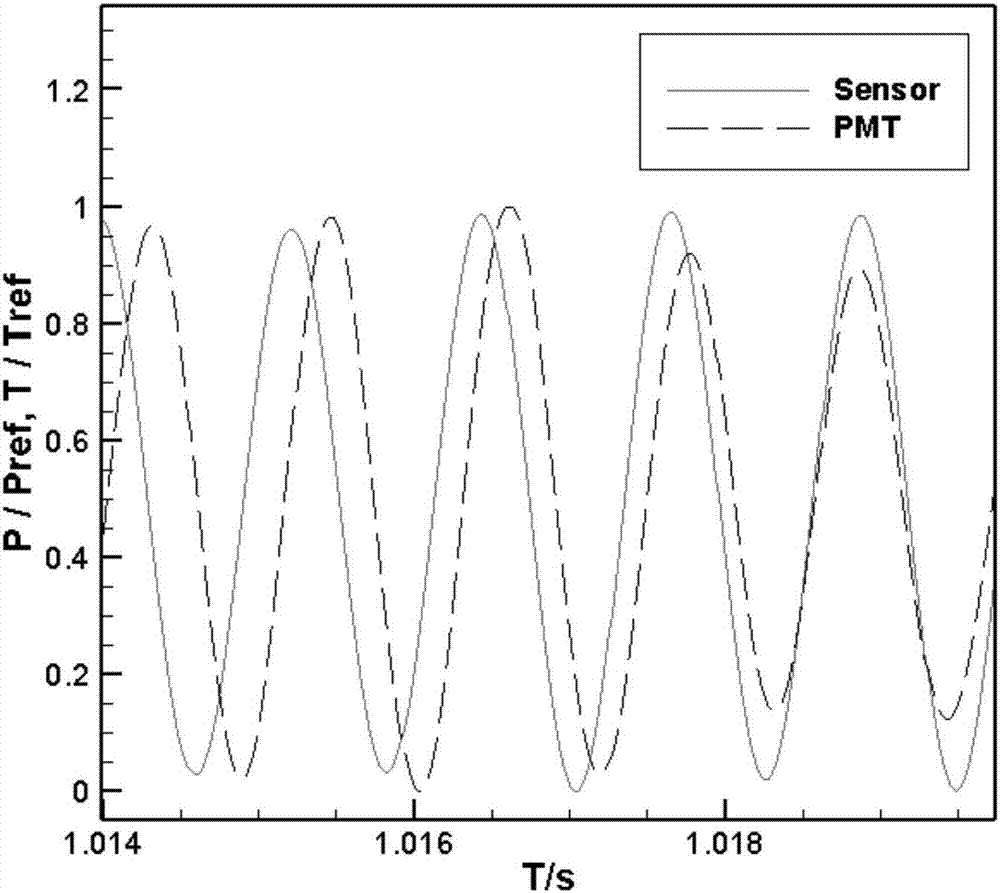

[0017] The calibration chamber of the invention is mainly used for dynamic pressure calibration of optical pressure-sensitive coatings, and can conduct dynamic calibration research on the frequency response characteristics of PSP coatings. The process of realizing dynamic calibration research measurement by relying on this calibration cabin is as follows:

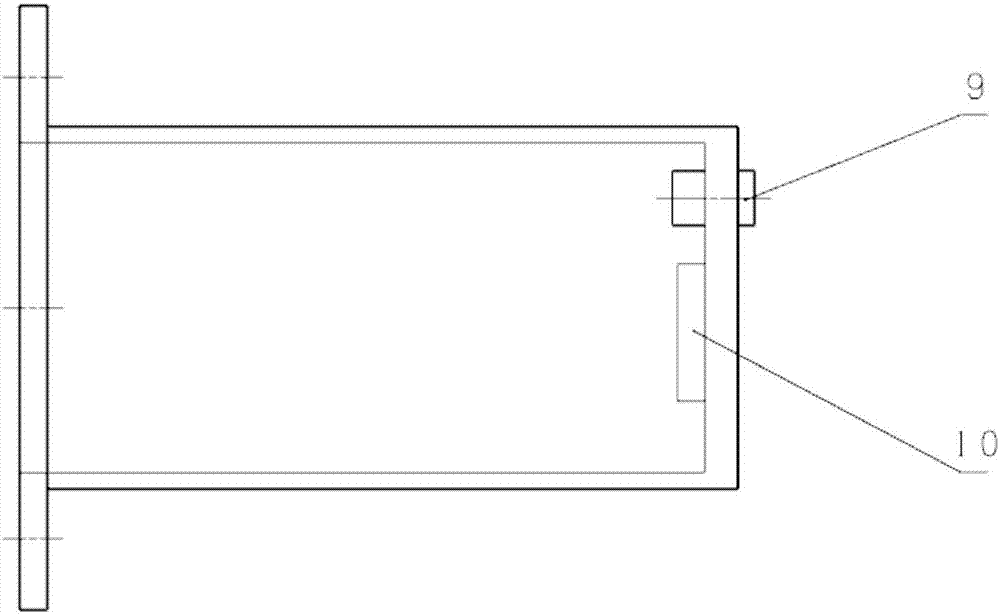

[0018] 1. Before the experiment, clean the surface of the calibration sheet (10), spray the measured optical pressure-sensitive paint and dry it. After the paint is cured, fix the calibration sheet on the reflective wall of the test section, with the side sprayed with the paint facing outward ,Such as figure 2 ;

[0019] 2. If figure 2 , pass the dynamic pressure sensor (9) through the reflective wall surface of the experimental section and fix and seal it. Note that the pressure sensing part of the sensor mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com