Temperature control system and method thereof

A temperature control system and controller technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve problems such as electrical noise, power factor fluctuation, improper temperature fluctuation, etc., to achieve effective use and improve power factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

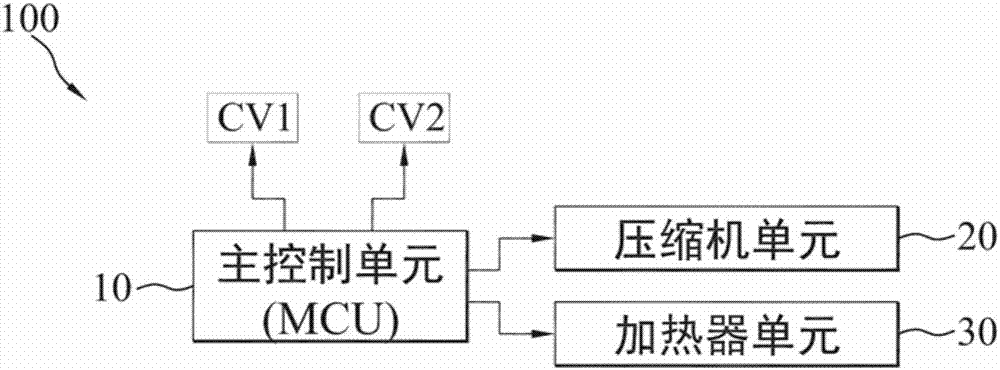

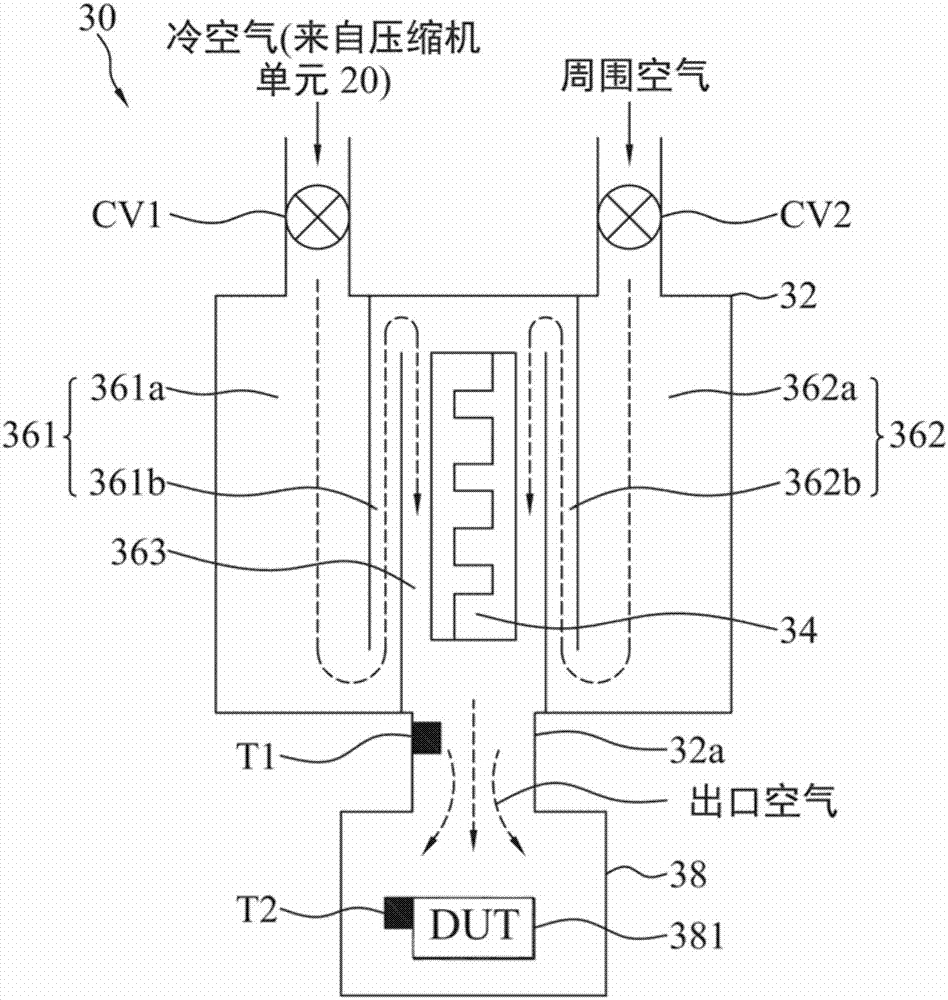

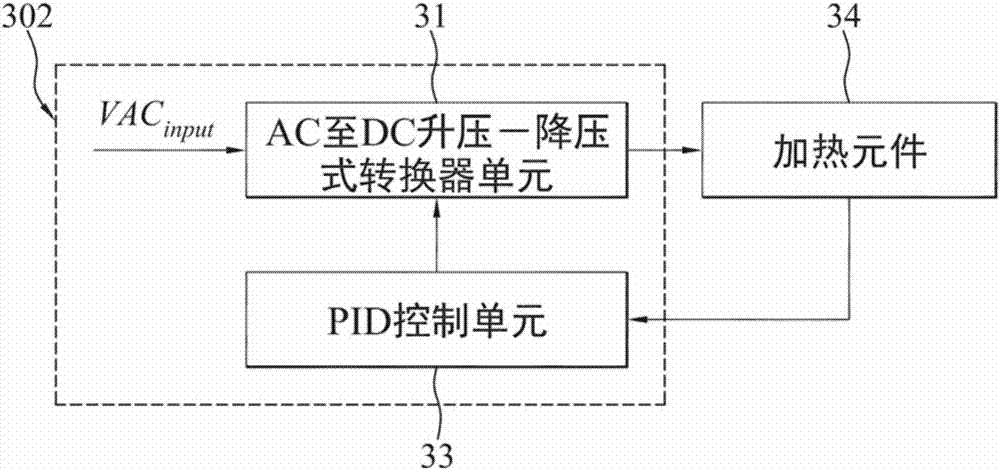

[0078] exist figure 1 In the figure is a temperature control system 100 used in an embodiment of the present invention to provide a description of the thermal management of a device under test or DUT (Device Under Test). The temperature control system 100 includes a main control unit (MCU) 10 , a compressor unit 20 and a heater unit 30 . The MCU 10 may be a processor having a plurality of I / O terminals respectively coupled to the first valve CV1, the second valve CV2, the compressor unit 20, and the heater unit 30 so that a signal can be sent to the first valve CV1 , the second valve CV2, the compressor unit 20 and the heater unit 30, and receive signals from the first valve CV1, the second valve CV2, the compressor unit 20 and the heater unit 30. The MCU 10 may control the first valve CV1 to adjust the flow of cool air (or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com