Design method for partition variable thickness composite laminate

A design method and technology of composite materials, applied in design optimization/simulation, calculation, special data processing application, etc., can solve the problems of variable thickness panel optimization problem, large amount of algorithm calculation, and no optimal solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

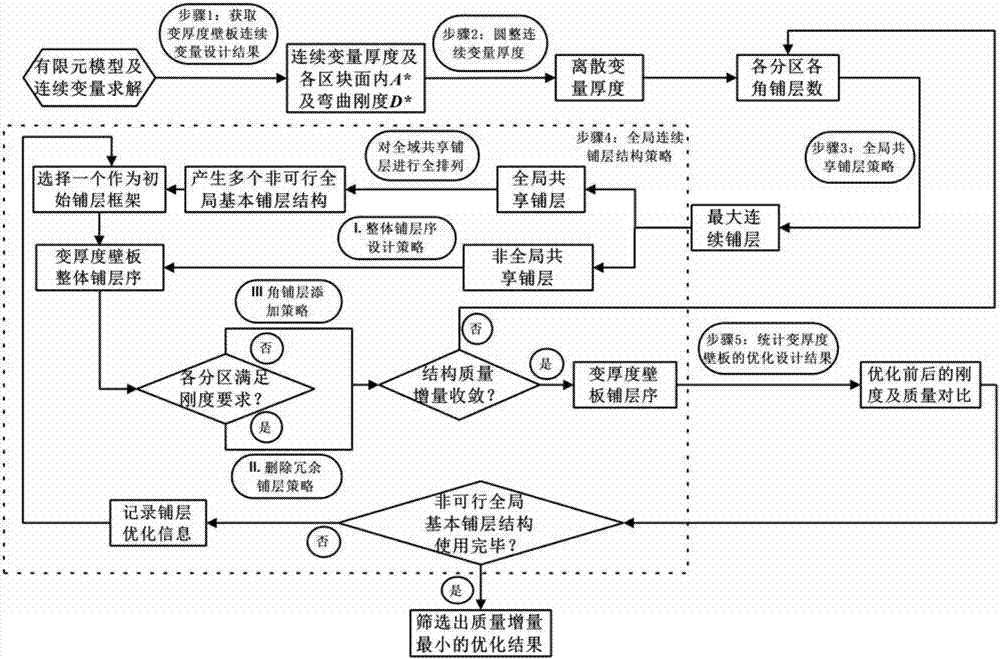

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

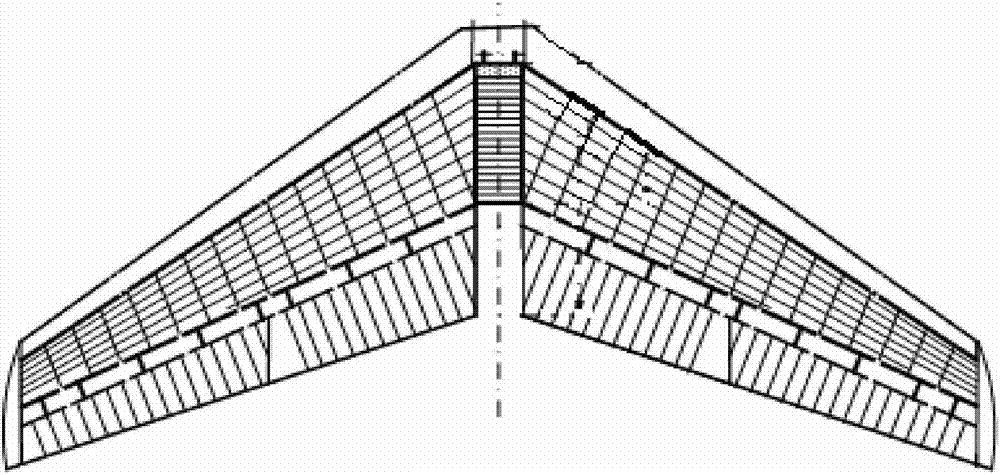

[0097] This embodiment is an optimal design process for a horizontal tail skin variable-thickness composite material panel structure.

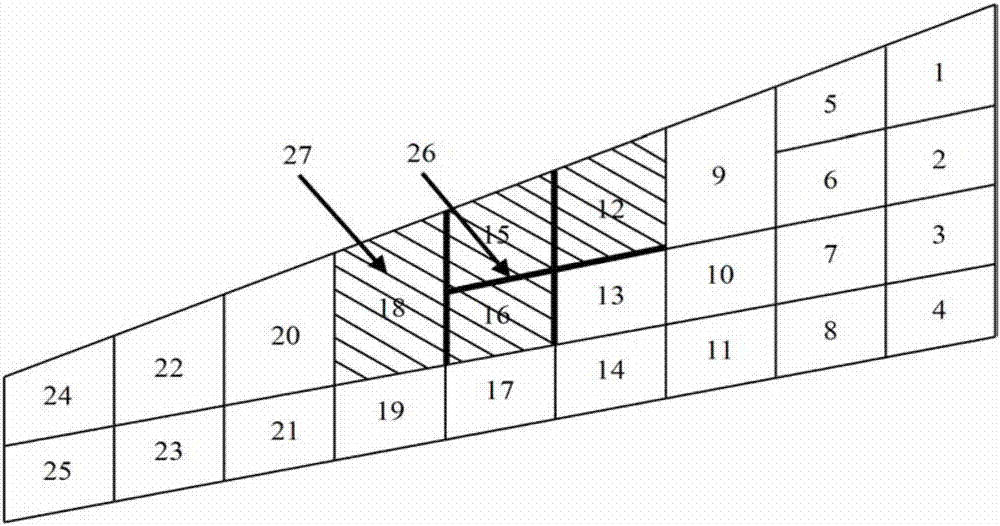

[0098] In the finite element modeling of the horizontal tail, the finite element discretization of the thin-walled structural members of the skin, beam web and rib web mainly adopts four-node quadrilateral shell elements and three-node triangular shell elements. The finite element discretization of Vitex all adopts two-node beam elements. Among them, the skin, beam web and rib web of the horizontal stabilizer and the elevator are all made of composite material shell elements, the connecting lugs between the horizontal stabilizer and the elevator are made of aluminum alloy shell elements, the stringers and beam edges of the horizontal stabilizer Composite material beam elements are used for ribs, ribs and tendons. attached figure 2 In order to establish the finite element model of the horizontal tail structure, the thickness partition of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com