Smart self-starting permanent magnet motor

A permanent magnet motor, self-starting technology, applied in asynchronous induction motors, magnetic circuits, electric components, etc., can solve the problems of low accuracy of test results, large dispersion of test data, low work efficiency, etc., and achieve significant energy-saving effects. The effect of improving protective performance and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

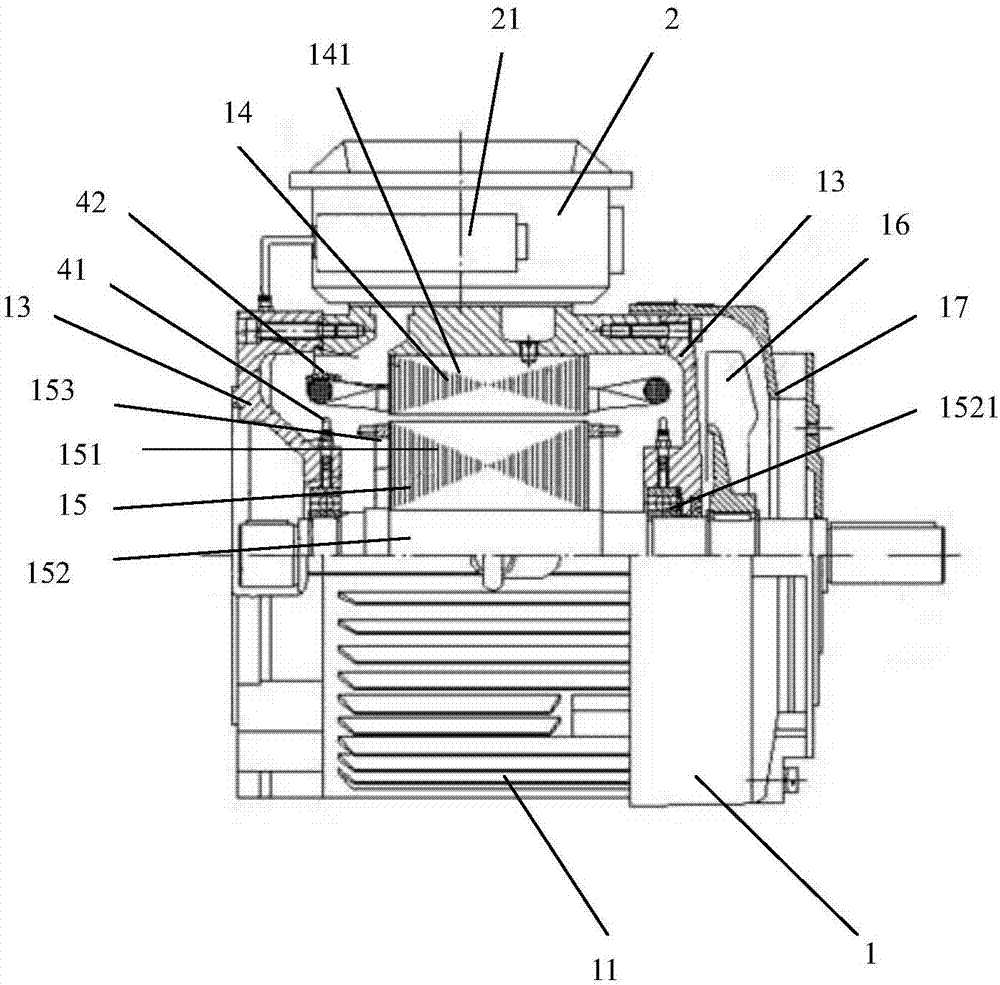

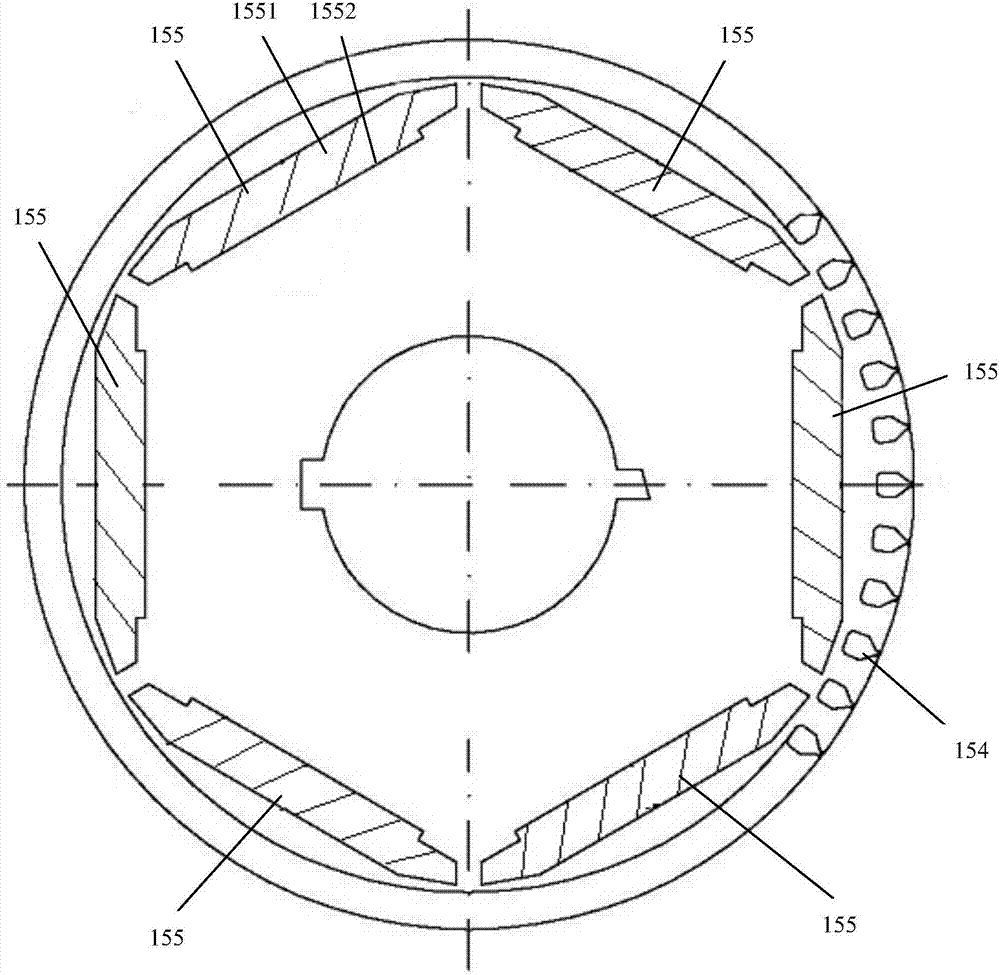

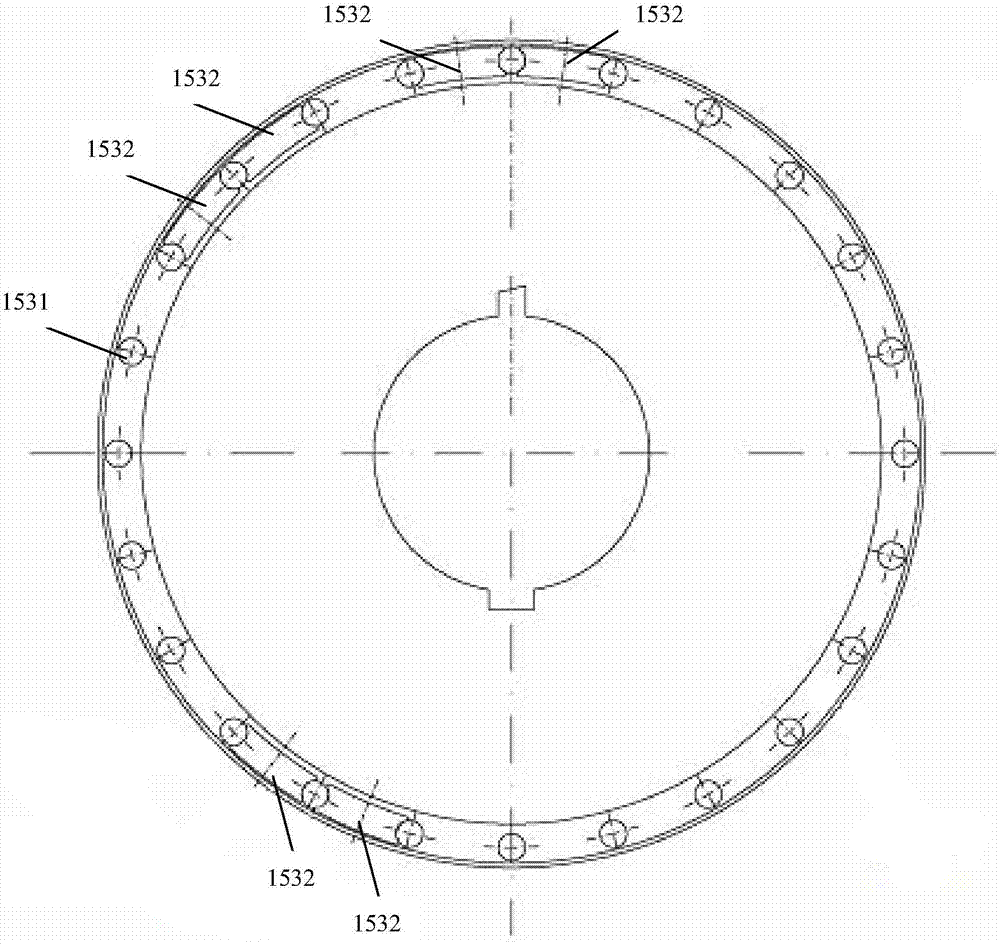

[0070] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 5 As shown, the cross-sections of several magnetic steel holes 155 are all stepped, and the cross-sections of several magnetic steel holes 155 include wide hole portions 1551 and narrow hole portions 1552, and the narrow hole portions 1552 of several magnetic steel holes 115 are all facing the stator punching sheet The center of the circle, the wide hole portions 1551 of the magnetic steel holes 155 are located outside the narrow hole portions 1552 .

[0071] In a further embodiment of the present invention, the enameled wire of the stator winding adopts Class F enameled wire.

[0072]In a further embodiment of the present invention, the windshield 17 is made of HT200 gray cast iron, and several air inlet holes are opened on the side of the windshield 17 . Compared with the existing windshields made of stretched thin steel plates or iron sheets, the mechanical strength and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com