Cavity equipment convenient to radiate

A cavity and equipment technology, applied in the construction parts of electrical equipment, electrical equipment housing/cabinet/drawer, cooling/ventilation/heating transformation, etc., can solve the problem of metal packaging that cannot play the role of sealing, mechanical support and physical protection Problems such as poor heat dissipation of the shell and poor stress on the joints of the components have achieved the effects of lowering the temperature, enhancing the structural strength, and reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

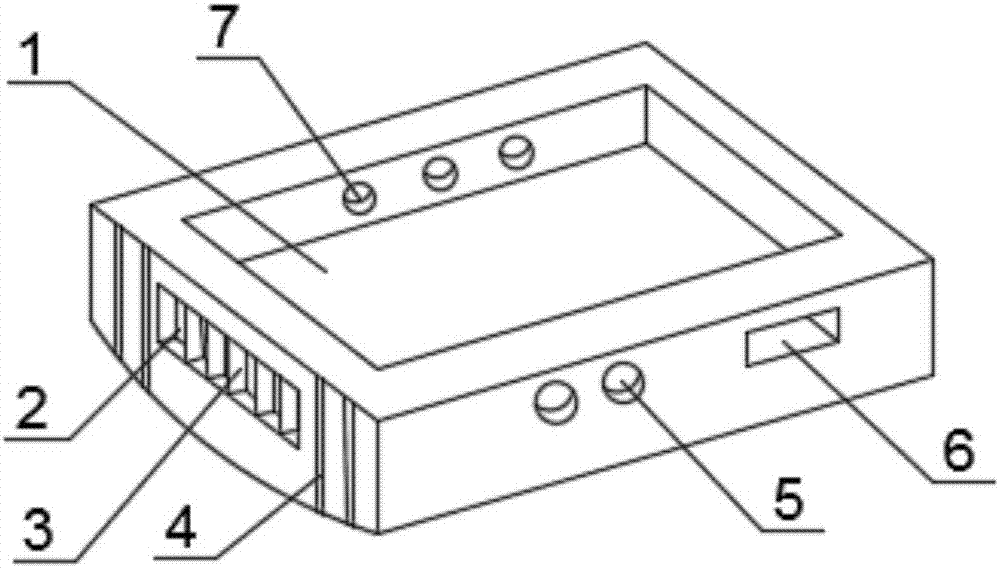

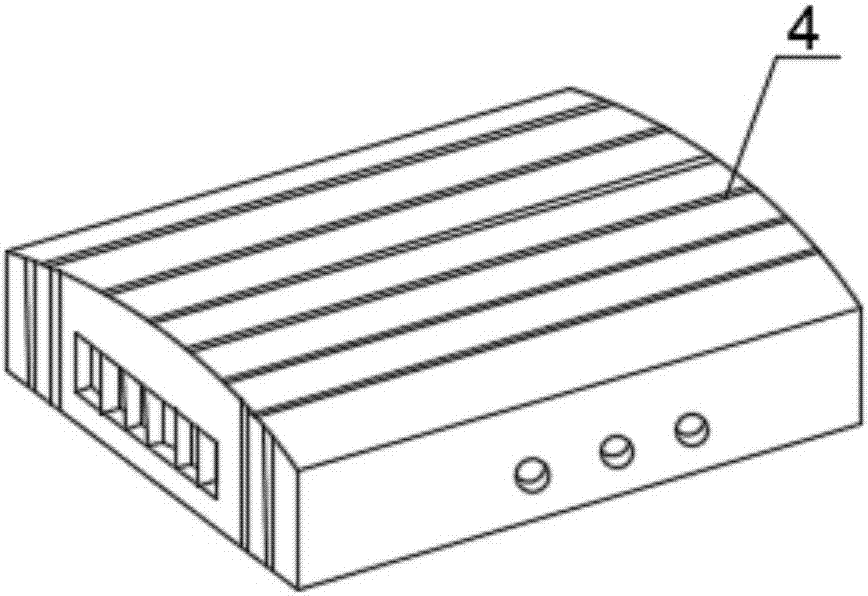

[0026] Such as figure 1 with figure 2 As shown, this embodiment provides a cavity device that facilitates heat dissipation. A concave cavity 1 is provided on the upper surface of the cavity body. The cavity body is an integrated structure. The left and right outer sides of the cavity body are respectively provided with There is a first groove 2, and a plurality of cooling fins 3 are arranged in the first groove 2; a plurality of second grooves 4 are respectively arranged on the left outer surface and the right outer surface of the cavity body, and the second groove 4 It does not intersect with the first groove 2; the lower surface of the cavity body is arc-shaped, and the lower surface of the cavity body is provided with a plurality of second grooves 4; in addition, the first groove 2, the heat sink 3 and the second The surfaces of the grooves 4 are all coated with heat-dissipating paint.

[0027] The front side of the cavity body is provided with a first round hole 5 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com