Natural dyestuff dyeing method for cellulosic fiber fabric

A technology of cellulose fibers and natural dyes, applied in the field of textile dyeing and finishing, can solve problems such as no similar reports, and achieve the effects of easy availability of raw materials, reduction of waste, and improvement of bonding fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

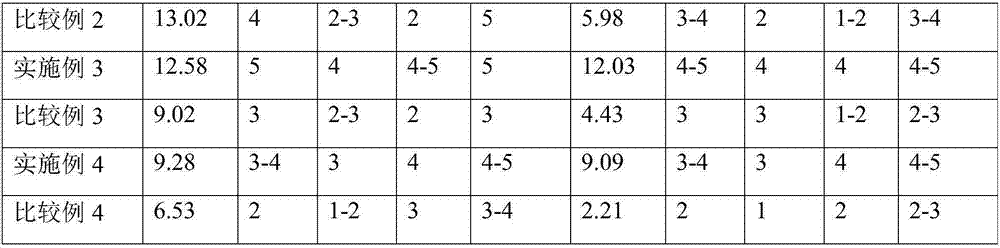

Examples

Embodiment 1

[0020] (1) Preparation of collagen hydrolyzate: Accurately weigh a certain amount of chrome-tanned leather leftovers, add it to a mass fraction of 10% NaOH solution, the ratio of chrome-tanned leather leftovers to NaOH solution mass is 1:8, Then hydrolyze at 80°C for 3 hours; after the hydrolysis is completed, filter to obtain a yellow viscous liquid that is collagen hydrolyzate, use glacial acetic acid to adjust the pH value of the hydrolyzate to neutral, and set aside;

[0021] (2) Cellulosic fiber fabric pretreatment: Accurately measure 100mL of the above collagen hydrolyzate, immerse the cotton fabric in the collagen hydrolyzate, dip twice and roll twice, the excess rate is 80%, pre-baked at 60°C for 10 minutes, and then soaked In a diisocyanate ethanol solution with a mass ratio of hexamethylene diisocyanate to absolute ethanol of 0.2:50, the crosslinking reaction time is 24 hours at 20°C. After the reaction, wash with water three times, dry at 80°C, and set aside;

[002...

Embodiment 2

[0030] (1) Preparation of collagen hydrolyzate: Accurately weigh a certain amount of aluminum tanned leather leftovers, add it into a 20% NaOH solution with a mass fraction, the ratio of aluminum tanned leather leftovers to NaOH solution mass is 1:16, Then hydrolyze at 100°C for 1 hour; after the hydrolysis is completed, filter to obtain a yellow viscous liquid, namely collagen hydrolyzate, use glacial acetic acid to adjust the pH value of the hydrolyzate to neutral, and set aside;

[0031] (2) Pretreatment of cellulose fiber fabric: accurately measure 100mL of the above-mentioned collagen hydrolyzate, immerse the hemp fabric in the collagen hydrolyzate, dip twice and roll twice, the excess rate is 90%, pre-baked at 75°C for 5 minutes, and then soaked In a diisocyanate ethanol solution with a mass ratio of p-phenylene diisocyanate to absolute ethanol of 0.6:50, the crosslinking reaction time is 12 hours at 50°C. After the reaction is completed, wash 5 times with water, dry at 8...

Embodiment 3

[0036] (1) Preparation of collagen hydrolyzate: accurately take a certain amount of iron-tanned leather leftovers, add it to a mass fraction of 15% NaOH solution, the ratio of iron-tanned leather leftovers to NaOH solution mass is 1:10, Then hydrolyze at 90°C for 2 hours; after the hydrolysis, filter to obtain a yellow viscous liquid that is collagen hydrolyzate, use glacial acetic acid to adjust the pH value of the hydrolyzate to neutral, and set aside;

[0037] (2) Cellulosic fiber fabric pretreatment: Accurately measure 100mL of the above-mentioned collagen hydrolyzate, immerse the viscose fabric in the collagen hydrolyzate, dip twice and roll twice, with a surplus rate of 85%, pre-baking at 65°C for 8 minutes, and then Soak in toluene-2,4-diisocyanate and absolute ethanol with a mass ratio of 0.4:50 diisocyanate ethanol solution, cross-linking reaction time at 40°C for 18h, after the reaction, wash 4 times with water, and dry at 82°C ,spare;

[0038] (3) Dyeing with natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com