Solar energy air drying device for cold-rolled steel plates

A cold-rolled steel plate and air-drying device technology, which is applied in solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problems of oil contamination, dust, etc., and achieve the effect of convenient layout, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Typical implementations of the present invention will be described below in conjunction with specific drawings.

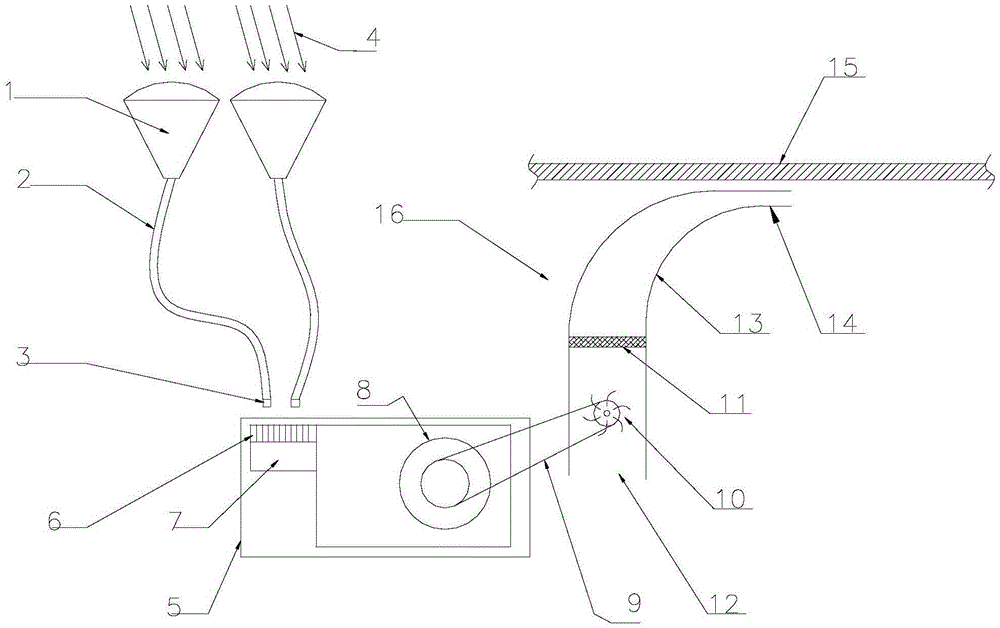

[0018] Such as figure 1 Shown:

[0019] The cold-rolled steel solar air-drying device mainly consists of a condenser lens (1), an optical fiber (2), a light scattering head (3), a Stirling engine (5), a conveyor belt (9), a fan (10), and a filter layer ( 11), composed of a gooseneck fan (16); the condenser lens (1) with light-condensing effect is placed under sunlight (4), one end of the optical fiber (2) is connected to the focus position of the condenser lens (1), and the other end is connected to The light-scattering head (3); the light-scattering head (3) is facing the heat-absorbing sheet (6) of the heat chamber of the Stirling engine; the engine power output wheel (8) drives the fan (10) through the transmission belt (9).

[0020] The heat absorbing fins (6) of the heat chamber of the Stirling engine are of a finned structure, and are fixed on the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com