Fluorine-containing single ion conductor polymer electrolyte and its preparation method and application

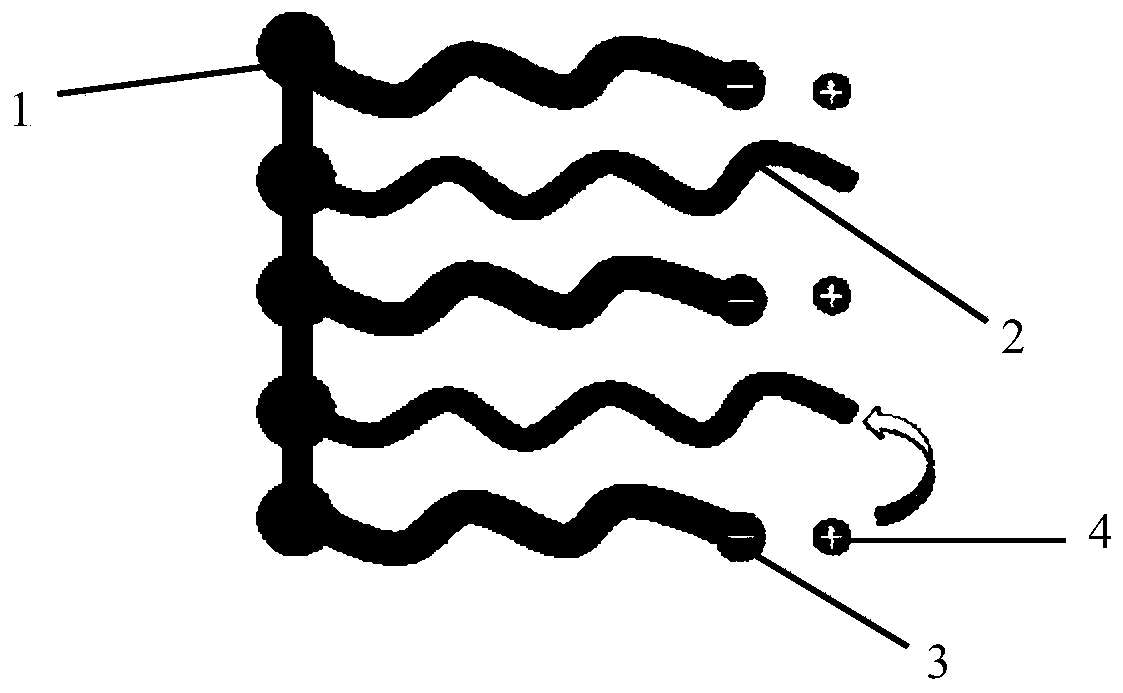

A conductor polymer, single-ion technology, used in the manufacture of electrolyte batteries, solid electrolyte fuel cells, non-aqueous electrolyte batteries, etc., can solve the problem of reducing battery energy efficiency and service life, reducing battery charge and discharge stability, and low cation migration and other problems, to achieve the effect of improving battery safety, satisfying mechanical properties, and high ion migration number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

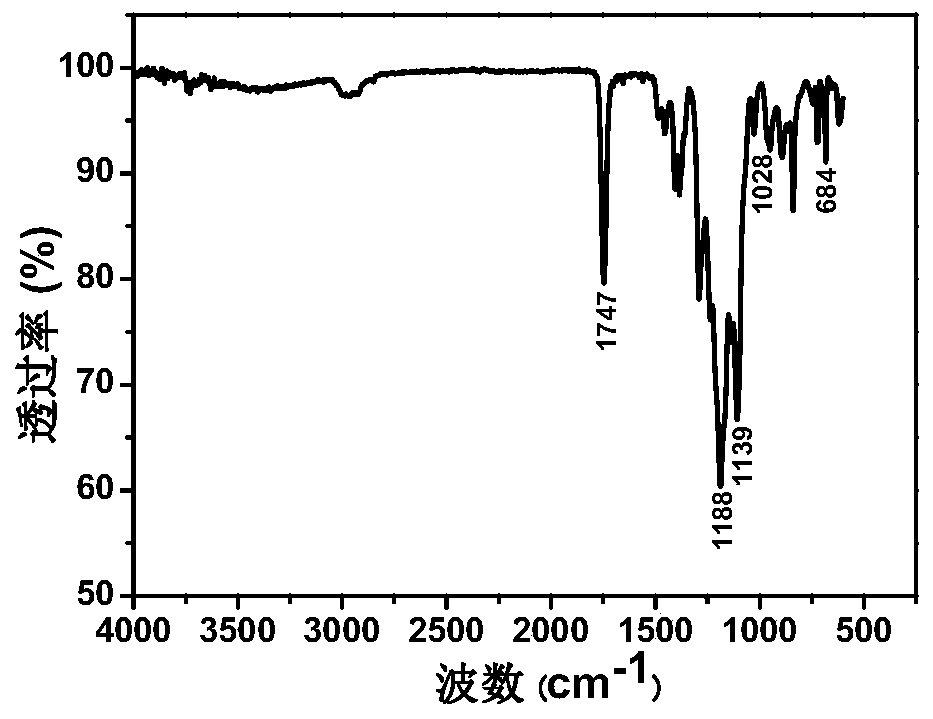

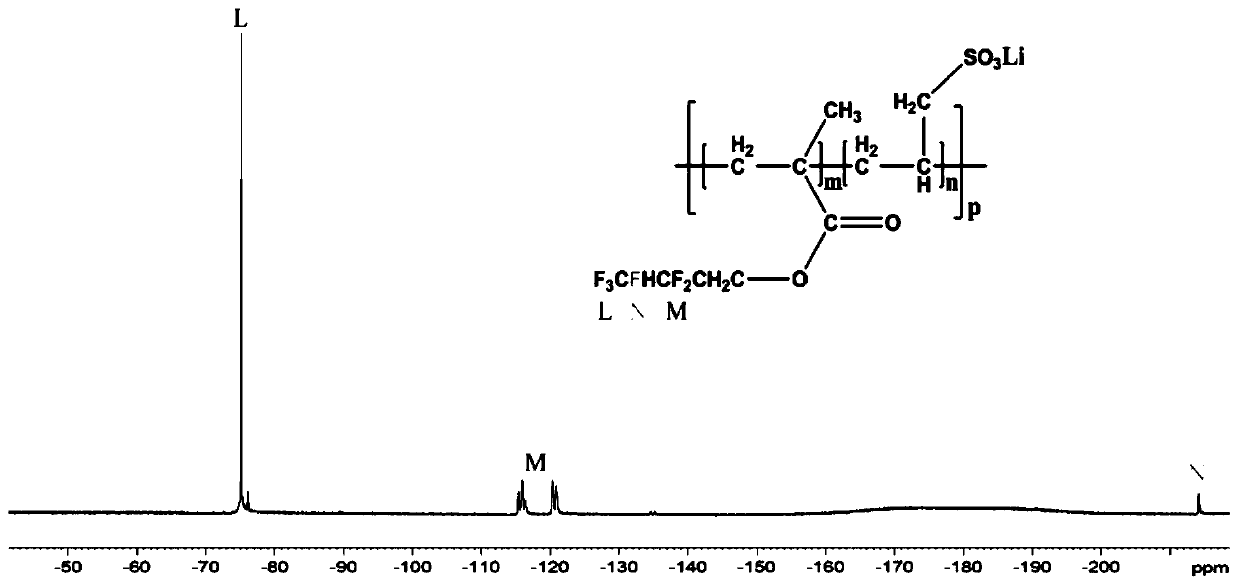

[0048] Add 0.025mol of hexafluorobutyl methacrylate, 0.025mol of sodium allyl sulfonate, 5ml of methanol and 0.020g of azobisisobutyronitrile into a three-necked flask, and place it in a 65°C oil bath under nitrogen protection In the device, stir and reflux for 12h. The product was washed three times with methanol and water to remove unreacted monomer and initiator. The product was dissolved in N, N-dimethylformamide and then precipitated in a precipitating agent. The dissolution and precipitation were repeated three times and dried at 80°C to obtain a fluorine-containing single ion conductor polymer with sulfonate functional groups.

[0049] Fully dissolve 0.5g of the above-mentioned dried polymer in 15ml of N,N-dimethylformamide, let stand in vacuum for 2h to defoam, cast the solution on a clean glass plate to form a film, and dry at 60°C for 24h. Place the cast membrane in 0.5 mol / L H 2 SO 4 In the solution, replace with new 0.5mol / L H every 6h 2 SO 4 solution, soaked ...

Embodiment 2

[0073] Add 0.025mol of trifluoroethyl methacrylate, 0.050mol of sodium p-styrene sulfonate, 5ml of methanol and 0.050g of azobisisobutyronitrile into a three-necked flask, and place it in a 65°C oil bath under nitrogen protection In the device, stir and reflux for 12h. The product was washed three times with methanol and water to remove unreacted monomer and initiator. The product was dissolved in N, N-dimethylformamide and then precipitated in a precipitating agent. The dissolution and precipitation were repeated three times and dried at 80°C to obtain a fluorine-containing single ion conductor polymer with sulfonate functional groups.

[0074] Fully dissolve 0.5g of the above-mentioned dried polymer in 15ml of N,N-dimethylformamide, let stand in vacuum for 2h to defoam, cast the solution on a clean glass plate to form a film, and dry at 60°C for 24h. A fluorine-containing single-ion conductor polymer electrolyte membrane with sodium sulfonate functional groups is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com