Technical process of fragrant and sweet black tea powder for tea noodle food

A technology of sweet and fragrant black tea and processing technology, which is applied in the direction of tea treatment before extraction, etc., to achieve the effect of tea activity, increased utilization, and outstanding sweetness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

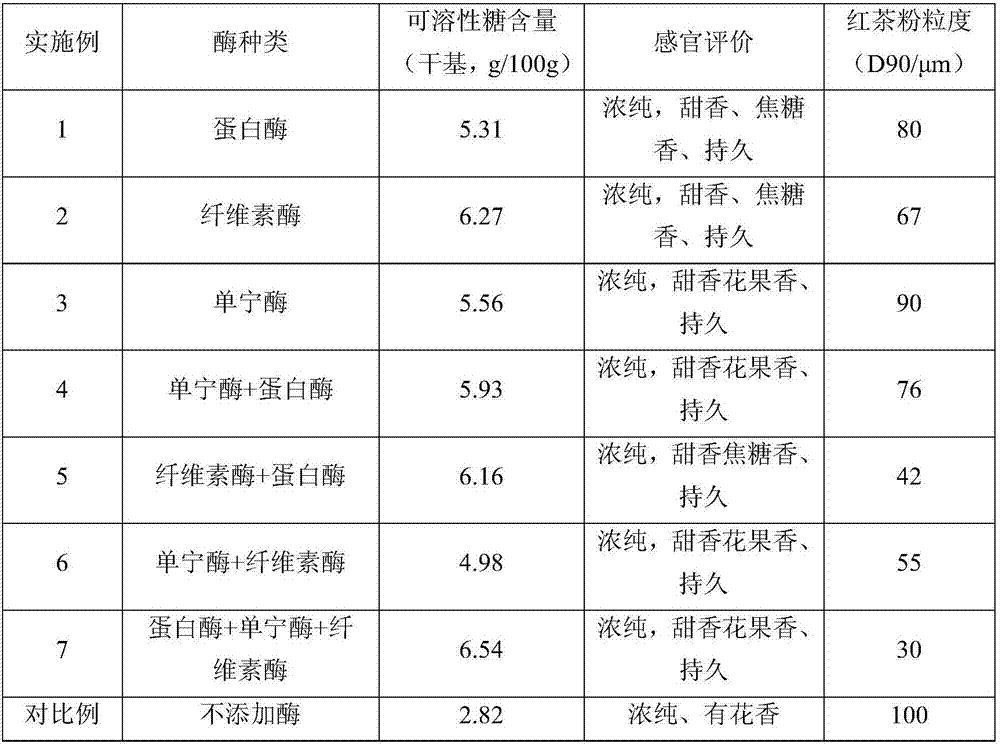

Examples

Embodiment 1

[0040] according to figure 1 The process shown carries out processing of sweet and fragrant black tea powder.

[0041] (1) sweet and fragrant black tea processing (single enzyme)

[0042] a. Fresh leaves: Fresh leaves with one bud and two or three leaves in summer and autumn are used as raw materials, which are disease-free and pest-free;

[0043] b. Withering: fresh leaves are picked and put into the withering tank. The thickness of the fresh leaves is 12cm, the ambient air humidity is 88%, and the ambient temperature is 25°C. Open the withering tank for ventilation and adjust the temperature to 30°C. When withering for 15 hours, the moisture content of the fresh leaves is 62%. stop withering;

[0044] c. Kneading-biological enzymatic hydrolysis compound: put 2.04kg of withered leaves in the Φ40cm kneading barrel of the kneading machine, knead with light pressure at room temperature 25°C for 20min, add papain (EC 3.4.22.2, 50,000 activity units / g, the same below ) 15.02g, ...

Embodiment 2

[0050] The processing technology is the same as that of Example 1, the difference is that the rolling-biological enzymolysis compound process is specifically: put 2.01kg of withered leaves in the Φ40cm kneading barrel of the rolling machine, knead with light pressure at room temperature for 20min at 25°C, add cellulase (EC3 .2.1.4, 20,000 activity units / mL, the same below) 3mL, knead under heavy pressure for 7min, then knead under medium pressure for 40min.

Embodiment 3

[0052] The processing technology is the same as that of Example 1, the difference is that the rolling-biological enzymatic hydrolysis compound process is specifically: 2.04 kg of withered leaves are placed in the Φ40 cm barrel of the rolling machine, and the room temperature is 25 ° C for 20 minutes under light pressure, and tannase (EC 3.1.1.20, 500 vitality units / g, the same below) 1.50g, knead under heavy pressure for 10min, then knead under medium pressure for 60min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com