Fast assembly press grinding plate for sander and manufacturing method thereof

A production method and technology of sanding machine, which are applied in abrasive belt grinders, chemical instruments and methods, grinders, etc., can solve the problems of short service life, waste, non-wearability, etc., and achieve long wear-resistant service life and convenient replacement and use. , good sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

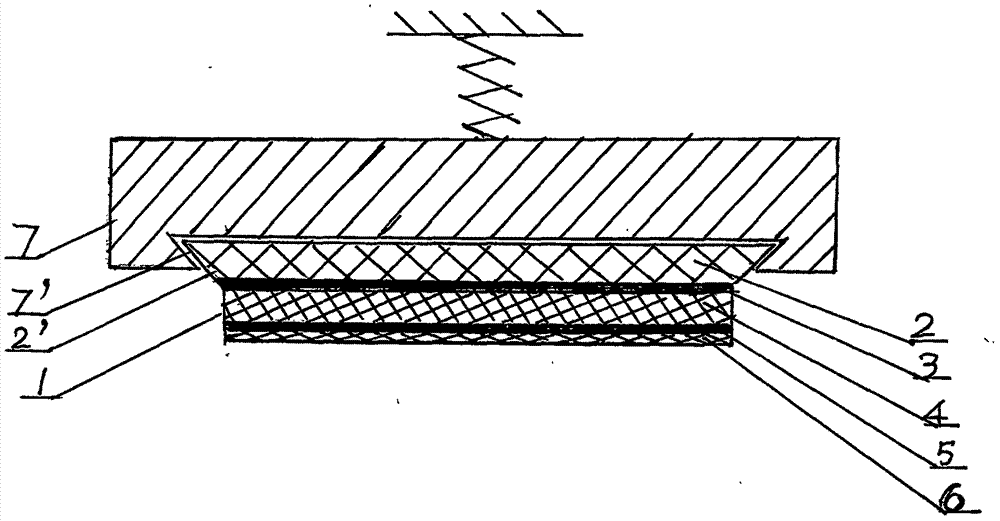

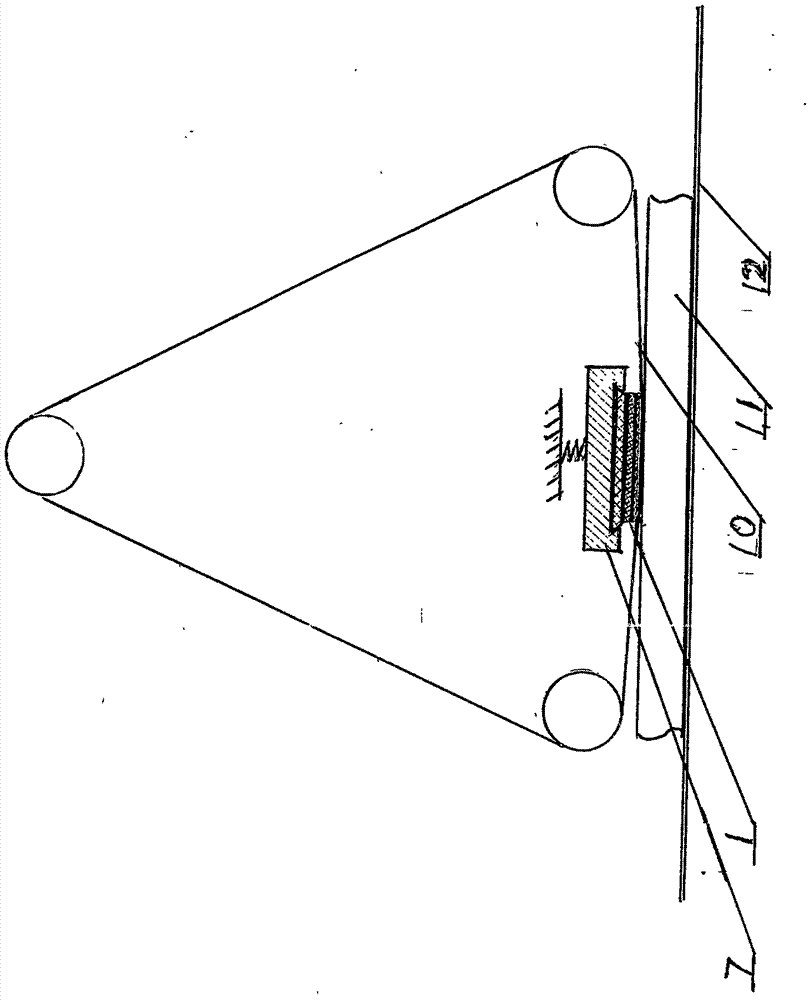

[0019] A fast-loading press plate 1 for a sanding machine is sequentially composed of a base plate 2, an elastic buffer pad 4, and graphite cloth 6 bonded and compounded with each other through an adhesive. The two sides of the base plate 2 have inclined grooves 2 ′ or concave-convex grooves, which can be mated with the corresponding inclined grooves 7 ′ or concave-convex grooves of the grinding plate base 7 .

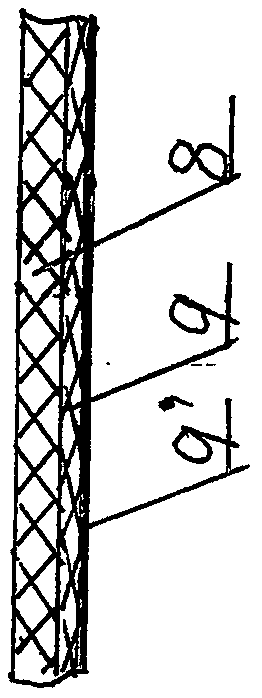

[0020] A further embodiment is that the substrate 2 can be a wood fiber board, or a wood-plastic board, or a plastic board, or an acrylic board, or a composite material board, and its thickness is 5-8 mm. It can also be a steel strip plate with a thickness of 0.5-1 mm. The elastic buffer pad 4 can be a wool felt pad, or a needle-punched non-woven felt pad, or an artificial leather pad, or a resin foam sheet, or a compressed sponge pad, and its thickness is 3-5mm. The graphite cloth 6 is composed of a canvas 8 with a thickness of 0.4-0.5 mm, and a mixed coating of grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com