Mixing apparatus used for ternary one-time foaming for refrigerator

A mixing device and refrigerator technology, which is applied in the field of mixing devices, can solve the problems of high thermal conductivity of alkane blowing agent, poor insulation effect of insulation layer, and increased probability of cracking, etc., to achieve stable mixing effect, reduced influence of corrosion and swelling, and corrosion The effect of reducing the chance of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

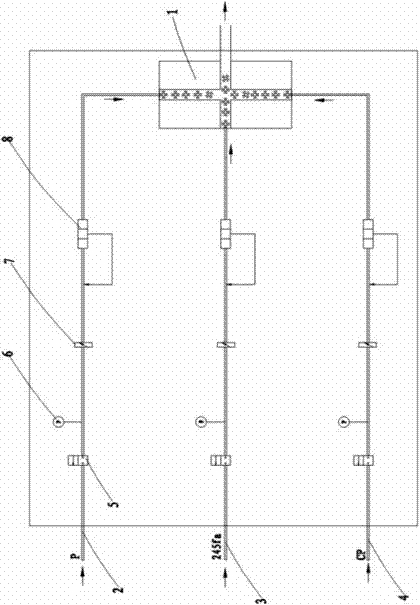

[0017] Example: Combine figure 1 , the refrigerator of the present embodiment uses a ternary foaming and mixing device, which includes: a static mixer 1, and a polyether pipeline 2, a pentafluoropropane pipeline 3 and a cyclopentane pipeline are respectively provided in the static mixer 1 4 communicates with it. In the polyether pipeline 2, a two-way valve 5, a pressure gauge 6, a flow meter 7 and a three-way valve 8 are sequentially provided between the feed end and the static mixer; similarly, in the pentafluoropropane pipe In the road 3 and the cyclopentane pipeline 4, a two-way valve, a pressure gauge, a flow meter and a three-way valve are also arranged sequentially from the feed end to the static mixer. figure 1 As shown, in each pipeline, there is a material loop between a channel of the three-way valve and the pipeline at the feed end. In specific applications, polyether polyol is conveyed in polyether pipeline 2, fluorocarbon foaming agent is conveyed in pentafluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com