Antibacterial sponge insole and preparation method thereof

The technology of sponge and insole is applied in the field of antibacterial sponge insole and its preparation, which can solve the problems of bacteria breeding, insole cannot perform long-term sterilization and deodorization, etc., and achieves the effects of avoiding breeding, low cost and reducing pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

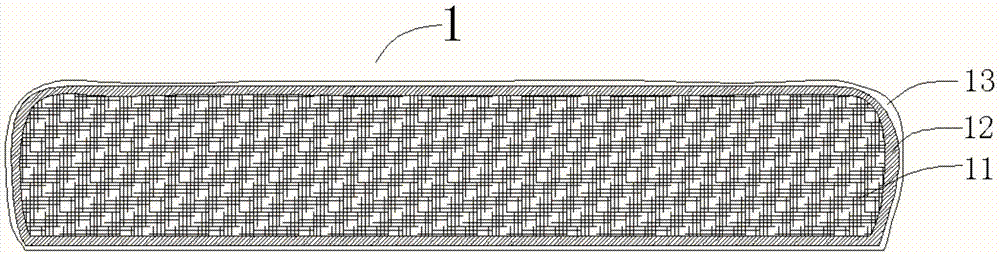

Image

Examples

Embodiment 1

[0026] (1) Add 100 parts by weight of polyether diol and 1 part by weight of graphene into a stirrer and stir at high speed for 20 minutes to obtain a uniformly mixed mixture.

[0027] (2) the compound of step (1) is mixed with the organic isocyanate of 40 weight parts, the water of 5 weight parts, the triethanolamine of the stannous octoate of 0.33 weight part and 0.42 weight part foaming and obtain antibacterial sponge.

[0028] (3) The sponge was cut into the shape of an insole, the outer surface was covered with cotton cloth, the middle of the two was evenly coated with white latex, and then hot-pressed at 200° C. for 20 seconds to obtain a molded antibacterial sponge insole.

Embodiment 2

[0030] (1) Add 100 parts by weight of polyether diol and polyether triol mixture and 3 parts by weight of graphene into a mixer and stir at high speed for 30 minutes to obtain a uniformly mixed mixture.

[0031] (2) the compound of step (1) is mixed with the organic isocyanate of 45 parts by weight, the water of 8 parts by weight, the triethylenediamine of 0.35 parts by weight of stannous octoate and 0.5 parts by weight of triethylenediamine is mixed and foamed to obtain an antibacterial sponge.

[0032] (3) The sponge obtained in step (2) is cut into the shape of an insole, the outer surface is covered with cotton cloth, the middle of the two is evenly coated with superglue, and then hot-pressed at 205° C. for 30 seconds to obtain a molded antibacterial sponge insole.

Embodiment 3

[0034] (1) Add 100 parts by weight of polyether trihydric alcohol and 1 part by weight of graphene into a mixer and stir at high speed for 20 minutes to obtain a uniformly mixed mixture.

[0035] (2) the mixing material of step (1) is mixed with the diphenylmethane diisocyanate of 40 parts by weight, the water of 5 parts by weight, the dibutyltin of 0.28 parts by weight and the triethanolamine of 0.35 parts by weight are mixed and foamed to obtain antibacterial sponge.

[0036] (3) The sponge obtained in step (2) is cut into the shape of an insole, the outer surface is covered with cotton cloth, the middle of the two is evenly coated with hot melt adhesive, and then hot-pressed at 195°C for 20 seconds to obtain a molded antibacterial sponge insole .

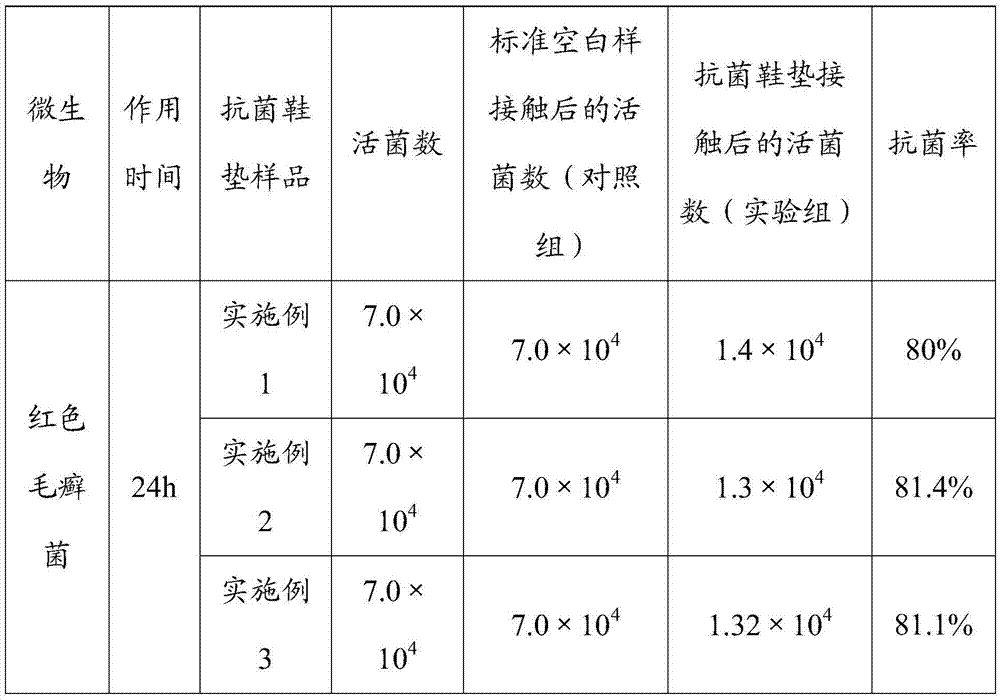

[0037] The antibacterial sponge insole prepared by the above three embodiments was tested for its antibacterial rate, and the test results are shown in Table 1.

[0038] Table 1

[0039]

[0040] The above results show that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com