Cu-based bulk and amorphous alloy composite and preparation method thereof

A technology of amorphous alloys and composite materials, applied in the field of material science, can solve problems such as increased cost and complexity of pre-deformation process, unfavorable in-situ formation of strong and tough phases, poor work hardening ability, etc., and achieves obvious work hardening ability and tensile strength Plasticity, the effect of solving room temperature brittleness and strain softening, and high hardness mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

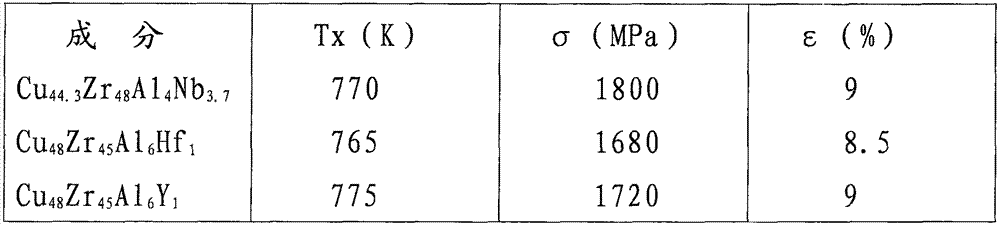

Embodiment 1

[0010] Using Cu, Zr, Al, Nb four elements, according to the mass of each alloy master ingot 10g, prepare Cu 44.3 Zr 48 Al 4 Nb 3.7 The weight of each component of the amorphous alloy is used to prepare a bulk amorphous composite material with a diameter of 3 mm.

Embodiment 2

[0012] Using Cu, Zr, Al, Hf four elements, according to the mass of each alloy master ingot 10g, prepare Cu 48 Zr 45 Al 6 f 1 The weight of each component of the amorphous alloy is used to prepare a bulk amorphous composite material with a diameter of 4 mm.

Embodiment 3

[0014] Using Cu, Zr, Al, Y four elements, according to the mass of each alloy master ingot 10g, prepare Cu 48 Zr 45 Al 6 Y 1 The weight of each component of the amorphous alloy is used to prepare a bulk amorphous composite material with a diameter of 5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com