Composite fiber membrane and preparing method and application thereof

A technology of composite fiber membrane and composite fiber, which is applied in fiber treatment, spinning solution preparation, textile and papermaking, etc., can solve the problems such as the decrease of mechanical strength of the film, and achieve simple preparation method, remarkable effect, good dimensional stability and durability thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

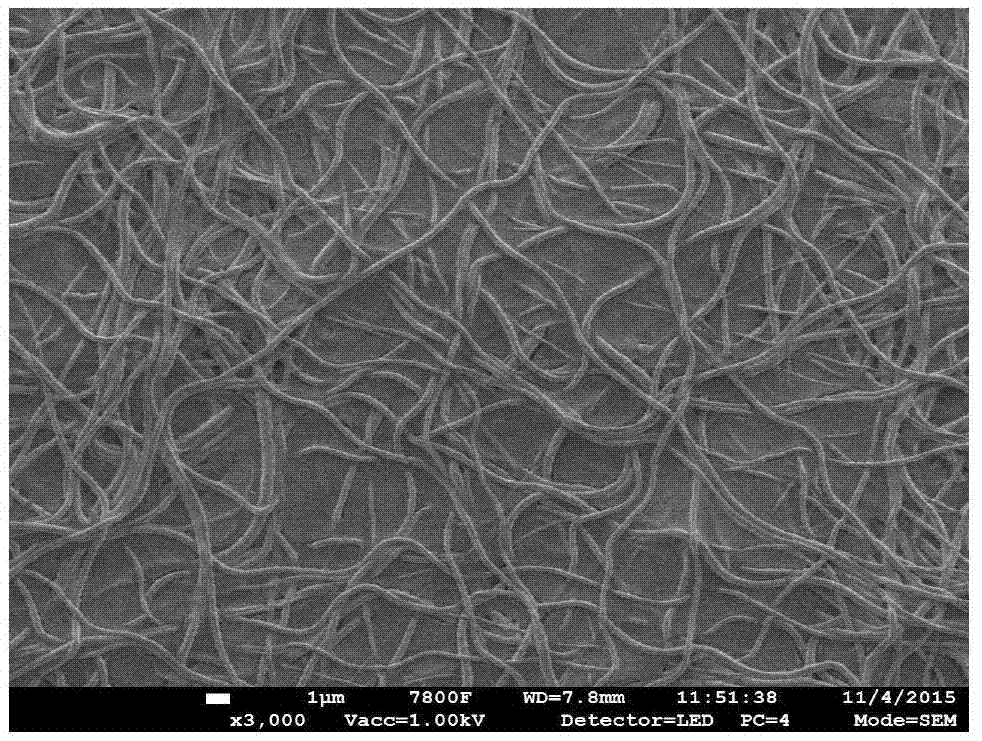

[0035] 1g poly(2,2`-(m-phenyl)5,5`-bibendazole) (mPBI) was dissolved in 15.7g N,N'-dimethylacetamide to prepare a solid content of 6.0wt% 0.01 g of polyoxyethylene was added as a carrier to prepare the spinning solution of polybenzimidazole. 1g of polyvinylidene fluoride (PVDF) was dissolved in 4g of N,N'-dimethylacetamide to prepare a clear spinning solution with a solid content of 20.0wt%. Cover the electrospinning receiving roller with aluminum foil, transfer 5mL mPBI and 5mL PVDF spinning solution into the electrospinning tube respectively, and fix them on both sides of the electrospinning receiving roller, and set the distance from the spinneret to the cathode to the cathode. Set at 20cm, advance speed at 0.04mL / min, spinning voltage at 20KV, use electrospinning tube needle as anode and aluminum foil as cathode to collect two kinds of nanofibers at the same time until all liquid is spun completely. Put the aluminum foil and the collected composite fibers in the steam of ...

Embodiment 2

[0037] 1g of mPBI was dissolved in 15.7g of N,N'-dimethylacetamide to prepare a clear solution with a solid content of 6.0wt%, and 0.01g of polyoxyethylene was added as a carrier to prepare a polybenzimidazole spinning solution. 1g of PVDF was dissolved in 4g of N,N'-dimethylacetamide to prepare a clear spinning solution with a solid content of 15wt%. Wrap the electrospinning receiving roll with aluminum foil, divide 10mL mPBI into two equal parts and transfer them to two electrospinning tubes, and place them on one side of the electrospinning roll; transfer 5mL PVDF spinning liquid to the built-in electrospinning tube On the other side of the electrospinning receiving roller, the distance from the spinneret to the cathode to the cathode is set to 20cm, the advancing speed is 0.04mL / min, and the spinning voltage is 20KV. The needle of the electrospinning tube is used as the anode, and the aluminum foil is used as the cathode. Both nanofibers were collected until the entire liq...

Embodiment 3

[0039]1g of mPBI was dissolved in 15.7g of N,N'-dimethylacetamide to prepare a clear solution with a solid content of 6.0wt%, and 0.01g of polyoxyethylene was added as a carrier to prepare a polybenzimidazole spinning solution. Dissolve 1g of PVDF in 4g of N,N'-dimethylacetamide to prepare a clear spinning solution with a solid content of 15wt%. Wrap the electrospinning receiving roll with aluminum foil, divide 10mL mPBI into two equal parts and transfer to two electrospinning tubes, place on one side of the electrospinning roll; transfer 2.5mL PVDF spinning solution to the electrospinning tube Built into the other side of the electrospinning receiving roller, the distance from the spinneret to the cathode to the cathode is set to 20cm, the advancing speed of the mPBI solution is set to 0.04mL / min, the advancing speed of the PVDF solution is 0.02mL / min, and the spinning voltage is 16.6 - 21KV, the needle of the electrospinning tube is used as the anode, and the aluminum foil i...

PUM

| Property | Measurement | Unit |

|---|---|---|

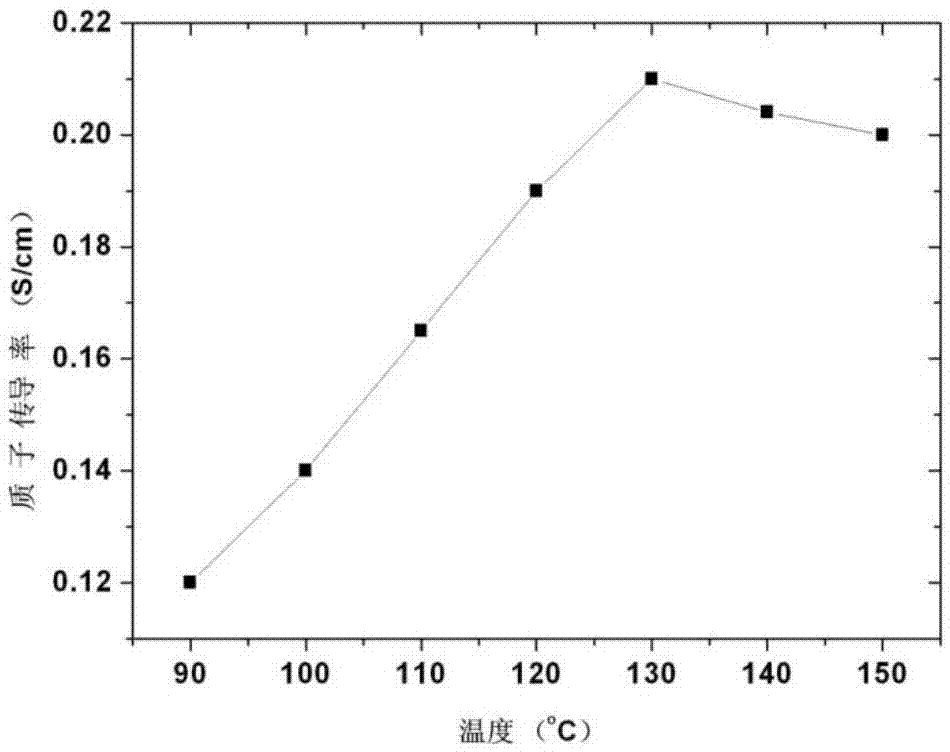

| Proton conductivity | aaaaa | aaaaa |

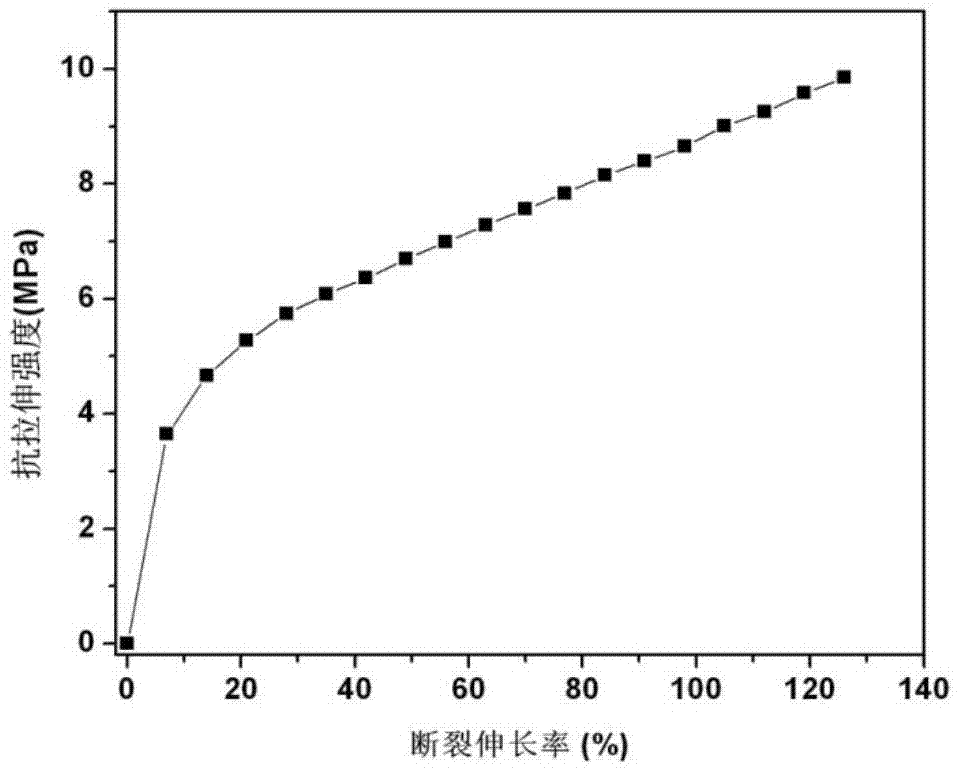

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com